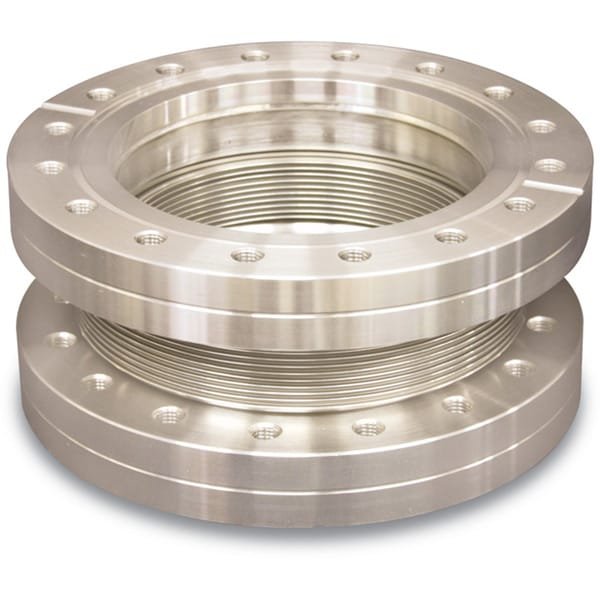

CF Flanged Edge-Welded Bellows for UHV Systems

We produce CF flanged edge-welded bellows for ultra-high vacuum (UHV) systems using durable 347 stainless steel hoses paired with 304L stainless steel knife-edge (ConFlat) flanges. Unlike hydraulically formed metal hoses, edge-welded bellows offer superior flexibility and naturally return to their original length—typically halfway between their extended and compressed states—when not subjected to vacuum conditions. The CF flange is the industry standard for high vacuum and UHV applications, providing compatibility with various gauges, instruments, accessories, and feedthroughs.

Key Features of Edge-Welded Bellows

- Exceptional flexibility

- Automatic spring-back to natural length when vacuum is not applied

- Maximum bakeout temperature of 250°C for stainless steel

Reviews

There are no reviews yet.