Strontium Lanthanum Aluminate Substrate (LaSrAlO₄)

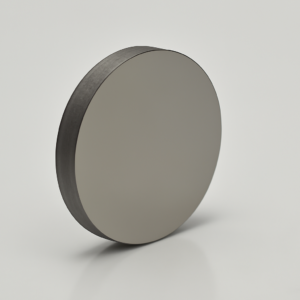

TFM offers high-quality Strontium Lanthanum Aluminate (LaSrAlO₄) substrates, known for their excellent chemical stability, high dielectric constant, and superior lattice matching with various oxide materials. These substrates are ideal for epitaxial growth of thin films, particularly in optoelectronics, superconductivity, and high-frequency applications.

LaSrAlO₄ substrates exhibit exceptional thermal stability and low thermal expansion, making them suitable for high-performance electronic devices and quantum material research. Their high refractive index and transparency in the visible and infrared ranges make them useful in optical coatings and photonics. Additionally, LaSrAlO₄ substrates are often used in complex oxide systems where high-quality interface formation is crucial.

TFM supplies customized LaSrAlO₄ substrates, offering precise specifications for a wide range of applications, from electronic devices to advanced material research, ensuring optimal performance and reliability.

Key Physical Properties

| Property | Value |

|---|---|

| Material | LaSrAlO₄ (Strontium Lanthanum Aluminate) |

| Structure | M4 |

| Lattice (A) | a=3.756, c=12.63 |

| Growth Method | Czochralski |

| Melting Point | 1650℃ |

| Density | 5.92 g/cm³ |

| Hardness | 6-6.5 (Mohns) |

| Permittivity | ε = 16.8 |

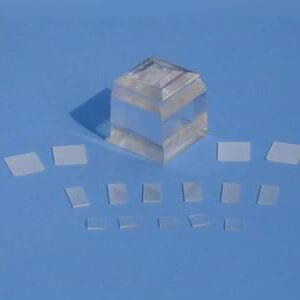

Specifications

- Size: 10×3 mm, 10×5 mm, 10×10 mm, 15×15 mm, 20×20 mm, Dia 15 mm, Dia 20 mm, Dia 1”, Dia 2”

- Thickness: 0.5 mm, 1.0 mm

- Polishing: SSP or DSP

- Orientation: <001>

- Redirection Precision: ±0.5°

- Angle of Crystalline: Custom sizes and orientations available

- Surface Roughness (Ra): ≤5Å (5µm × 5µm)

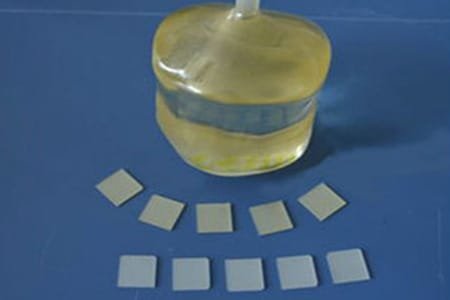

Packaging Details

Strontium Lanthanum Aluminate substrates are securely packaged in class 100 clean bags or wafer containers in a class 1000 clean room, ensuring optimal cleanliness and protection.

Choose Strontium Lanthanum Aluminate Substrates from TFM for high-quality thin films and reliable performance in advanced semiconductor applications.

Reviews

There are no reviews yet.