Introduction

Aluminum substrates are widely used base materials in thin-film deposition, electronic packaging, thermal management, and general industrial applications. Thanks to aluminum’s excellent thermal conductivity, low density, good electrical conductivity, and ease of machining, Aluminum (Al) substrates provide a versatile and cost-effective solution for both research and industrial environments. They are commonly selected where efficient heat dissipation, mechanical stability, and process compatibility are essential.

Detailed Description

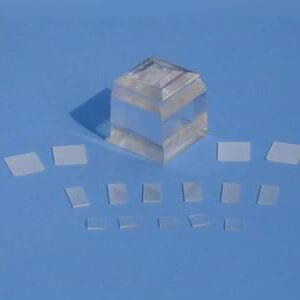

Aluminum is a lightweight metal with high thermal conductivity and good corrosion resistance, especially when surface-treated or used in controlled environments. As a substrate material, aluminum offers a stable platform for thin-film coatings, metallization layers, and functional surface treatments.

Our Aluminum substrates are manufactured from high-purity aluminum using precision cutting, grinding, and polishing processes to ensure consistent thickness, flatness, and surface quality. Substrates can be supplied with as-machined, fine-ground, or polished surfaces, depending on the requirements of sputtering, evaporation, plating, or coating processes.

Aluminum substrates are compatible with a wide range of deposition techniques, including Physical Vapor Deposition (PVD), thermal evaporation, electron-beam evaporation, and electrochemical processes. Their high thermal conductivity makes them particularly suitable for applications involving heat-generating devices or high-power coatings. Custom dimensions, thicknesses, and surface finishes are available to support both laboratory research and industrial production.

Applications

Aluminum substrates are used across many industries and technical fields, including:

Thin-film deposition substrates for sputtering and evaporation

Thermal management and heat-spreading components

Electronic packaging and power device bases

Optical and decorative coatings

General R&D and prototype fabrication

Industrial coatings and surface engineering

Technical Parameters

| Parameter | Typical Value / Range | Importance |

|---|---|---|

| Material | Aluminum (Al) | Provides thermal & mechanical performance |

| Purity | 99.5% – 99.99% | Affects conductivity and film adhesion |

| Form | Plate / Disc / Custom shape | Fits different system requirements |

| Thickness | 0.5 – 20 mm (custom) | Determines strength & heat dissipation |

| Surface Finish | Machined / Ground / Polished | Influences coating quality |

| Thermal Conductivity | ~237 W/m·K | Enables efficient heat transfer |

| Density | ~2.7 g/cm³ | Lightweight structural advantage |

Comparison with Related Materials

| Material | Key Advantage | Typical Application |

|---|---|---|

| Aluminum (Al) | Lightweight, excellent thermal conductivity | Coatings, heat sinks |

| Copper (Cu) | Higher electrical & thermal conductivity | Power electronics |

| Stainless Steel | High strength, corrosion resistance | Structural substrates |

| Silicon | Semiconductor compatibility | Microelectronics |

FAQ

| Question | Answer |

|---|---|

| Can aluminum substrates be customized? | Yes, size, thickness, and surface finish can be tailored. |

| Are aluminum substrates suitable for sputtering? | Yes, they are widely used as substrates and backing materials. |

| What surface finishes are available? | Machined, fine-ground, and polished finishes are available. |

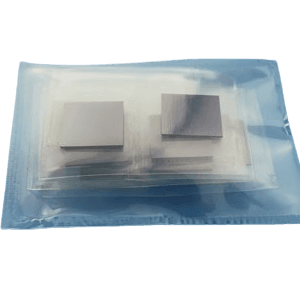

| How are the substrates packaged? | Individually protected to prevent scratches and contamination. |

Packaging

Our Aluminum Substrate (Al) products are meticulously tagged and labeled externally to ensure efficient identification and strict quality control. Each substrate is carefully protected with cushioning materials to prevent surface damage during storage and transportation, ensuring it arrives in excellent condition.

Conclusion

Aluminum substrates offer an ideal balance of performance, versatility, and cost efficiency. With excellent thermal conductivity, low weight, and broad process compatibility, they are a reliable choice for thin-film deposition, electronic, and industrial applications.

For detailed specifications and a quotation, please contact us at sales@thinfilmmaterials.com.

Reviews

There are no reviews yet.