Introduction

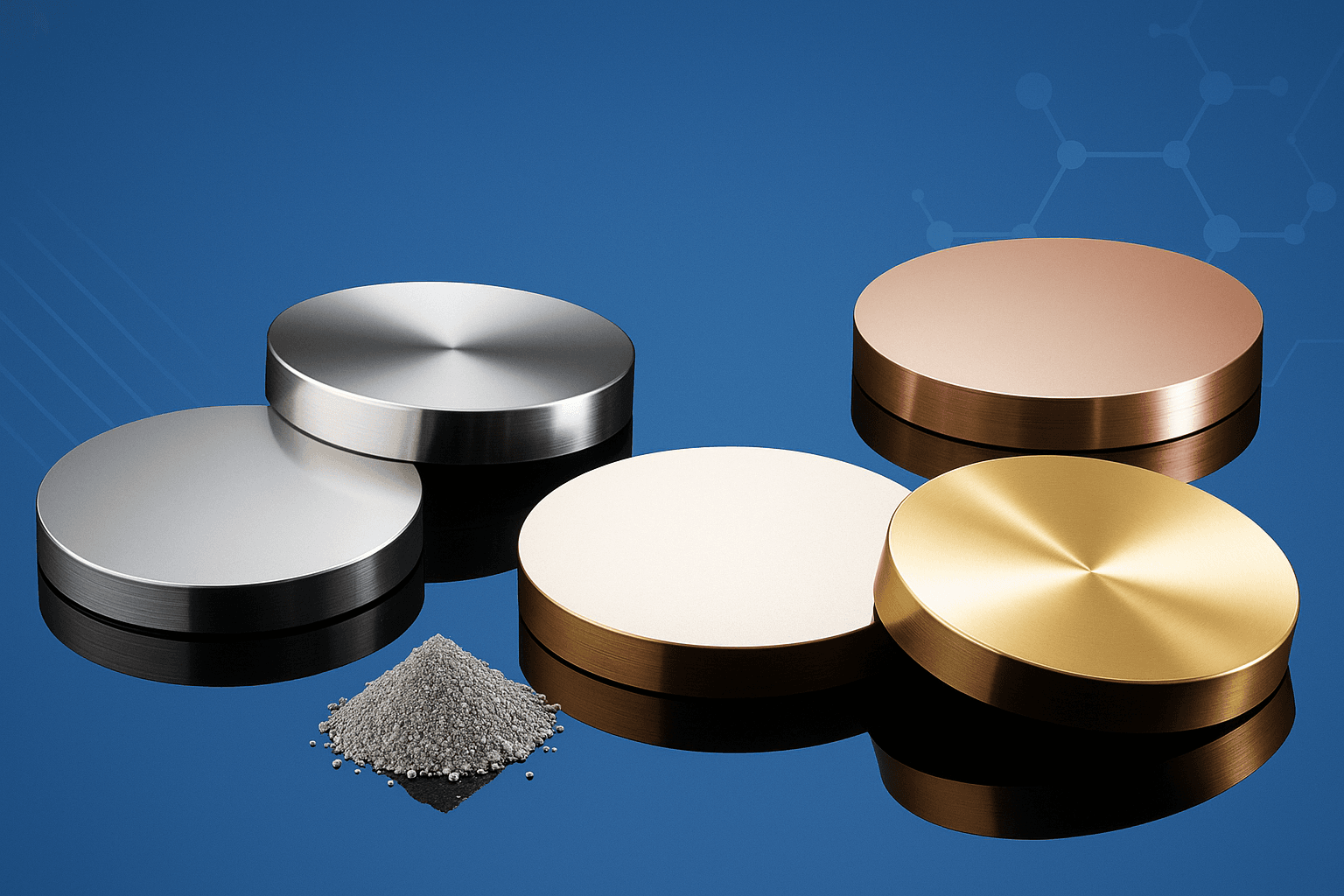

In the rapidly advancing field of thin film deposition, particularly in technologies such as physical vapor deposition (PVD) and magnetron sputtering, the choice of sputtering target plays a critical role in determining film quality, uniformity, and functionality. Among the diverse range of available sputtering materials, alloy sputtering targets and composite sputtering targets stand out as two distinct classes, each with unique material characteristics, fabrication techniques, and optimal application areas.

This article presents an in-depth comparative analysis of alloy and composite sputtering targets, focusing on their structural differences, manufacturing processes, advantages, limitations, and specific use cases in various industries such as semiconductors, optics, data storage, and energy devices. All insights are grounded in TFM’s extensive industry expertise in producing high-purity sputtering materials for advanced thin film applications.

1. Understanding Sputtering Targets

1.1 What is a Sputtering Target?

A sputtering target is a solid material from which atoms are ejected (“sputtered”) by high-energy particle bombardment in a vacuum chamber during the sputtering deposition process. The ejected atoms then deposit onto a substrate to form a thin film.

1.2 Classification of Sputtering Targets

Sputtering targets are broadly classified into:

- Elemental (Pure Metal) Targets

- Alloy Targets

- Composite Targets

- Ceramic and Compound Targets

Each type serves different purposes depending on the physical and chemical properties desired in the resulting thin film.

2. Alloy Sputtering Targets

2.1 Definition

Alloy sputtering targets are made from a solid solution or intermetallic compound of two or more elements that are melted and homogenized to form a single-phase or multi-phase material.

2.2 Manufacturing Process

- Melting and Casting: The constituent metals are melted together in a controlled atmosphere to form a homogenous alloy.

- Hot/Cold Rolling: The ingot is further processed to refine grain structure.

- Vacuum Annealing: To relieve internal stresses and ensure compositional uniformity.

- Machining and Bonding: Final machining to required dimensions and bonding to a backing plate if needed.

TFM employs strict vacuum melting protocols and microstructural analysis at each stage to ensure uniformity and reproducibility of our alloy targets.

2.3 Characteristics

- Uniform distribution of elements.

- Good mechanical stability and thermal conductivity.

- Better target density compared to composite targets.

2.4 Advantages

- High compositional stability during sputtering.

- Fewer interfacial defects.

- Suitable for high-power sputtering systems.

2.5 Limitations

- Limited to elements that are mutually soluble or form stable alloys.

- Expensive and complex manufacturing for high-purity or reactive element alloys.

3. Composite Sputtering Targets

3.1 Definition

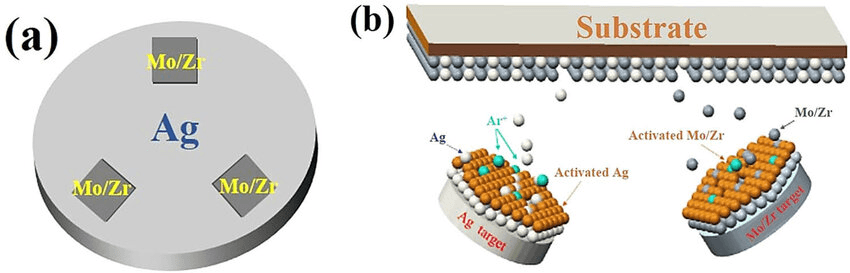

Composite sputtering targets consist of distinct elemental or compound segments, often in the form of discs or tiles, mechanically or metallurgically bonded together on a common backing plate.

3.2 Manufacturing Process

- Powder Pressing and Sintering: Individual powders are pressed and sintered into segments.

- Hot Isostatic Pressing (HIP): For densification and mechanical bonding.

- Segment Bonding: Final segments are bonded to a backing plate using indium, elastomer, or solder techniques.

At TFM, we ensure optimal bonding integrity through X-ray inspection and bonding strength validation for every composite target.

3.3 Characteristics

- Non-uniform phase distribution (by design).

- Customizable ratios by adjusting the area of segments.

- Easier to fabricate for materials with limited mutual solubility.

3.4 Advantages

- Cost-effective for complex or multi-component materials.

- Flexibility in tailoring composition.

- Quick prototyping for R&D.

3.5 Limitations

- Inhomogeneity in the sputtered film if poorly designed.

- Potential delamination of segments under high thermal stress.

- Lower thermal and mechanical stability compared to alloys.

4. Key Differences Between Alloy and Composite Targets

| Property | Alloy Target | Composite Target |

|---|---|---|

| Composition Uniformity | High | Medium to Low |

| Manufacturing Complexity | High | Moderate |

| Thermal Conductivity | Higher | Lower |

| Customizability | Limited | High |

| Material Compatibility | Requires solubility | No solubility needed |

| Film Consistency | Excellent | Depends on design |

| Cost | Higher for exotic alloys | More cost-effective |

5. Application Scenarios

5.1 Semiconductors and Microelectronics

- Alloy Targets: Used where uniform electrical or thermal properties are critical, e.g., Cu-Ni, Ti-W, or Al-Si alloys.

- Composite Targets: Ideal for test runs or devices requiring custom doping, e.g., segmented Ti-Si targets for gate electrodes.

TFM supports microelectronics manufacturers with tightly controlled compositions and film uniformity essential for advanced CMOS and RF structures.

5.2 Optical Coatings

- Alloy Targets: Preferred for materials like Cr-Al, Ni-V for hard coatings.

- Composite Targets: Used for complex multilayer stacks like MgF2-TiO2 where precise layer control is needed.

5.3 Data Storage Media

- Alloy Targets: CoPtCr and FePt alloys for high-density magnetic recording.

- Composite Targets: Research phase material combinations for spintronic devices.

5.4 Energy and Battery Materials

- Alloy Targets: Sn-Co, Si-Ti alloys for anode layers.

- Composite Targets: Li-based systems, where combining Li with transition metals can be achieved more easily through composites.

5.5 Research & Development

- Alloy Targets: When the final formulation is known and needs to be scaled.

- Composite Targets: For screening new material systems or varying compositions rapidly.

6. Quality Control and Performance Metrics

6.1 Key Parameters

- Density: Higher in alloys, affects sputter rate.

- Purity: Affects film quality; both types can reach >99.99%.

- Bond Strength: Crucial in composite designs.

- Surface Flatness: Influences film uniformity.

6.2 Failure Modes

- Cracking due to thermal stress.

- Delamination from backing plate.

- Compositional drift during sputtering.

TFM incorporates advanced nondestructive evaluation and post-bonding stress testing to ensure our targets perform reliably under demanding sputtering conditions.

7. Market Availability and Trends

7.1 TFM’s Offerings

TFM provides a full portfolio of alloy and composite sputtering targets, customizable to customer-specified compositions, geometries, and bonding requirements. Our R&D team works closely with partners to deliver rapid prototypes and production-grade targets for a wide range of deposition systems.

7.2 Trends

- Growing use of composite targets for flexible electronics.

- Alloy targets dominating in 5G, power devices.

- Hybrid targets (alloy + embedded segments) as emerging innovations.

Frequently Asked Questions (FAQs)

1. What is the main difference between an alloy sputtering target and a composite sputtering target?

Alloy targets are homogeneous materials formed by melting multiple elements, while composite targets consist of distinct segments or powders bonded together without melting.

2. Which sputtering target type offers better film uniformity?

Alloy targets generally provide superior film uniformity due to their homogeneous structure, especially in high-precision deposition processes.

3. Can TFM provide custom compositions for composite sputtering targets?

Yes. TFM specializes in customized composite targets, allowing clients to specify segment ratios, geometries, and bonding techniques.

4. Are composite targets suitable for high-power sputtering systems?

They can be, but alloy targets typically handle high thermal and mechanical stress better. Composite targets must be properly bonded and designed to avoid delamination.

5. How does target density affect sputtering performance?

Higher density targets (common in alloys) yield more consistent sputter rates, longer target life, and better film quality.

6. When should I choose a composite target over an alloy target?

Composite targets are ideal for prototyping, R&D, or when working with elements that are difficult to alloy, such as certain reactive or immiscible materials.

7. What bonding methods does TFM offer for composite targets?

TFM provides indium bonding, elastomer bonding, and solder bonding, each selected based on material compatibility and application requirements.

8. How does TFM ensure the quality of its sputtering targets?

TFM employs rigorous quality control, including X-ray inspection, ultrasonic testing, microstructural analysis, and post-bonding stress evaluation.

9. Can alloy and composite targets be used interchangeably?

Not always. The choice depends on the process conditions, desired film properties, and cost considerations. TFM provides technical guidance to help customers select the right target type.

10. What is the typical lead time for custom alloy or composite sputtering targets from TFM?

Lead times vary depending on complexity and volume, but TFM offers expedited production services and maintains stock for standard configurations.

8. Conclusion

Both alloy and composite sputtering targets have essential roles in thin film deposition processes. Alloy targets offer high purity, consistency, and structural stability, making them ideal for high-volume and precision-demanding applications. On the other hand, composite targets provide flexibility, affordability, and customization, especially beneficial in research, prototyping, and multi-component material development.

Understanding the differences between these two target types—and matching their characteristics with specific process requirements—is crucial for achieving optimal film performance and cost efficiency in modern materials engineering. TFM stands ready to support customers with expert guidance and high-quality sputtering target solutions tailored to their exact specifications.

Related Products

Pure Metal Targets