Niobium (Nb), a transition metal known for its superior conductivity, corrosion resistance, and superconducting properties, is a preferred material in the field of advanced thin film technology. In rotary sputtering systems, niobium rotary sputtering targets offer consistent performance, long target life, and enhanced material utilization—making them an ideal choice for large-area coatings, integrated circuits, and optical films.

TFM (Thin Film Materials) specializes in producing high-purity Niobium (Nb) Rotary Sputtering Targets tailored to meet the stringent requirements of modern PVD (Physical Vapor Deposition) applications. This comprehensive guide delves into the material properties, production techniques, advantages, and industrial applications of niobium rotary targets, with insights into why TFM is a trusted supplier in this space.

What Is a Niobium Rotary Sputtering Target?

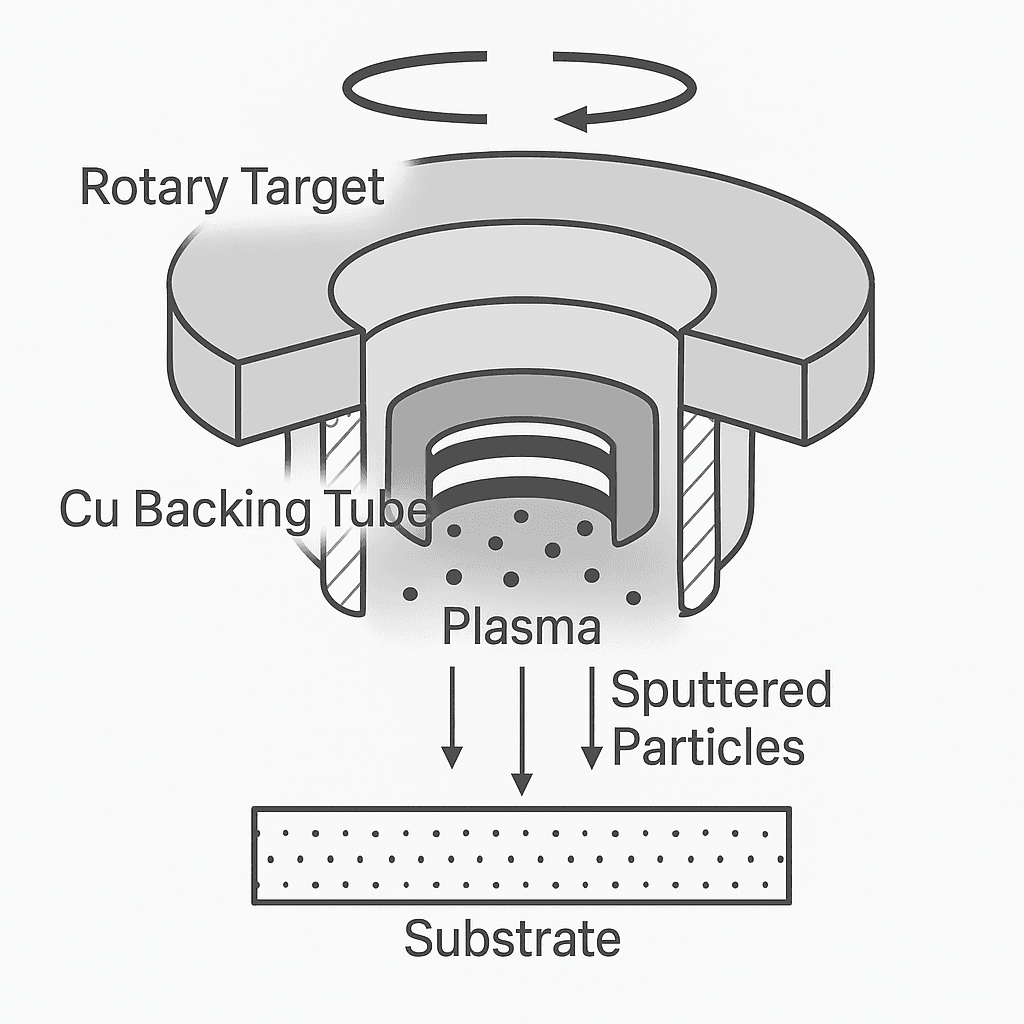

A Niobium Rotary Sputtering Target is a cylindrical-shaped target made from high-purity niobium metal, typically hollow inside, designed for use in rotating magnetron sputtering systems. Unlike planar targets, rotary targets rotate continuously during the sputtering process, allowing for a more uniform erosion profile, improved film thickness uniformity, and extended target life.

The rotary design is particularly advantageous in large-area coating processes and continuous film deposition lines such as architectural glass coating, photovoltaics, and flat panel displays.

Key Material Properties of Niobium (Nb)

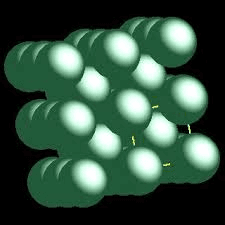

Understanding the intrinsic properties of niobium is essential to appreciate why it is selected for rotary sputtering targets.

- Element Symbol: Nb

- Atomic Number: 41

- Atomic Weight: 92.906

- Density: 8.57 g/cm³

- Melting Point: 2,468°C

- Electrical Resistivity: 15.2 µΩ·cm at 20°C

- Crystal Structure: Body-centered cubic (BCC)

- Purity Available: 3N5 (99.95%), 4N (99.99%), 4N5 (99.995%)

These properties make niobium ideal for applications requiring high-temperature stability, excellent conductivity, and compatibility with reactive gas atmospheres (like O₂ or N₂) during sputtering.

Advantages of Niobium Rotary Targets in Sputtering

1. High Utilization Efficiency

Rotary sputtering targets can achieve up to 80–90% material utilization, compared to around 30–40% for planar targets. This improves cost-efficiency, especially when using expensive materials like high-purity niobium.

2. Superior Uniformity

The rotating motion provides uniform erosion across the target surface, which translates to better film thickness uniformity across large substrates. This is critical in producing defect-free thin films in microelectronics and optics.

3. Longer Target Life

Niobium rotary targets offer significantly longer lifetimes compared to planar types, making them suitable for long production runs and reducing downtime for target replacement.

4. High Deposition Rates

Niobium, due to its high atomic mass and surface binding energy, allows high sputter yields in both DC and RF magnetron sputtering systems.

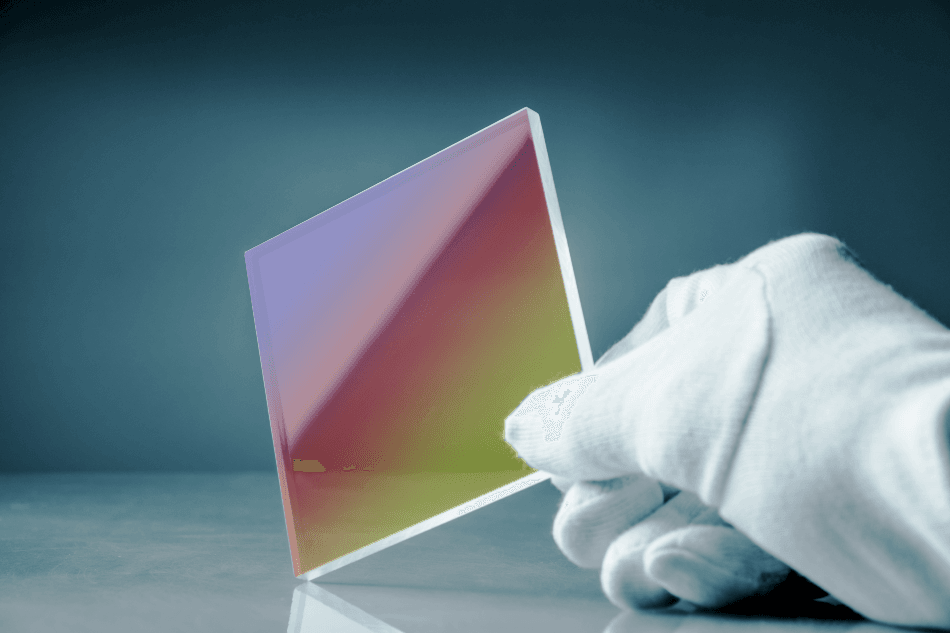

5. Stable Oxide Films

Niobium forms stable oxides (Nb₂O₅) that are transparent and dielectric in nature. These are widely used in optical coatings, fuel cells, and memory storage devices.

Common Applications of Niobium Rotary Sputtering Targets

Niobium thin films are integral to several cutting-edge technologies. Rotary sputtering targets enable scalable and high-throughput production for the following applications:

1. Optical Coatings

Niobium oxide (Nb₂O₅) thin films are used in anti-reflective coatings, beam splitters, and optical interference filters. They offer high refractive indices and wide bandgap properties.

2. Semiconductors and Microelectronics

Nb is used as a barrier layer and electrode in semiconductor devices, especially in CMOS, DRAM, and superconductor junctions due to its low resistivity and compatibility with silicon.

3. Superconducting Films

Niobium is a critical material in the production of superconducting thin films for MRI magnets, quantum computers, and particle accelerators.

4. Energy Storage and Conversion

Nb-based thin films are being researched for use in solid oxide fuel cells (SOFCs), Li-ion batteries, and electrochromic smart windows.

5. Photovoltaics

Niobium is used as a transparent conducting oxide (TCO) dopant and back contact material in thin-film solar cells such as CIGS and perovskite-based devices.

Manufacturing of TFM Niobium Rotary Sputtering Targets

At TFM, the production of niobium rotary targets follows strict quality control protocols and state-of-the-art metallurgy techniques.

Step 1: Raw Material Selection

TFM sources high-purity niobium ingots from certified suppliers. Only 3N5 and above purity levels are selected to ensure minimal contamination and high deposition quality.

Step 2: Vacuum Melting and Casting

Niobium is vacuum arc melted (VAM) or electron beam melted (EBM) to refine the metal and eliminate gaseous and metallic impurities.

Step 3: Rotary Tube Forming

The purified niobium is hot forged and rolled into tubular form, followed by cold isostatic pressing (CIP) or extrusion to shape the rotary target with precise inner and outer diameters.

Step 4: Heat Treatment

Homogenization and stress-relieving annealing are conducted to refine the microstructure and improve ductility.

Step 5: Machining and Surface Finishing

Advanced CNC machining is used to achieve tight dimensional tolerances. Surface polishing ensures optimal sputtering performance.

Step 6: Quality Inspection

TFM applies comprehensive QA testing, including:

- Chemical composition analysis (GDMS)

- Ultrasonic testing

- Grain size measurement

- Hardness and density testing

- Vacuum leak testing

Specifications of TFM Niobium Rotary Sputtering Targets

| Property | Specification |

|---|---|

| Material | Niobium (Nb) |

| Purity | 99.95%, 99.99%, 99.995% |

| Form | Hollow cylindrical tube |

| Outer Diameter | 100–300 mm (customizable) |

| Inner Diameter | 80–260 mm (customizable) |

| Length | Up to 3000 mm |

| Bonding | Available with indium or elastomeric bonding on copper backing tube (Cu B/T) |

| Surface Finish | Ra ≤ 0.8 μm |

| Density | >99.5% of theoretical |

Custom dimensions and bonding services are available based on system compatibility and customer request.

TFM’s Advantages as Your Niobium Target Supplier

1. Extensive Manufacturing Experience

TFM has decades of experience in producing rotary and planar sputtering targets, ensuring technical maturity and process stability.

2. High Purity Guarantee

Every batch of TFM niobium targets comes with traceable certificates and purity verification to meet semiconductor-grade demands.

3. Global Delivery and Support

TFM serves research labs, OEMs, and coating facilities worldwide with responsive logistics, custom packaging, and expert technical support.

4. Flexible MOQ & Customization

Whether for R&D or mass production, TFM accommodates varying order sizes and custom specifications.

5. Vacuum-Compatible Packaging

Each rotary target is cleaned, vacuum-sealed in inert atmosphere, and packed to prevent contamination or oxidation during transit.

Sputtering Process Optimization Tips

To achieve optimal performance when using TFM’s niobium rotary sputtering targets, consider the following:

- Pre-Sputtering: Always conduct pre-sputter cleaning under vacuum to remove surface oxides and contaminants.

- Reactive Atmosphere Control: For oxide films, control oxygen partial pressure accurately to avoid over-oxidation.

- Cooling Systems: Ensure efficient cooling of the backing tube to avoid thermal warping.

- Target Conditioning: Rotate slowly during ramp-up to uniformize erosion from the start.

FAQs About Niobium Rotary Sputtering Targets

Q1: What is the typical lifetime of a Nb rotary sputtering target?

A well-maintained niobium rotary target can last 2–3 times longer than a planar target under identical sputtering conditions.

Q2: Can TFM provide bonded targets?

Yes. TFM offers indium-bonded or elastomeric-bonded niobium rotary targets on copper backing tubes.

Q3: What is the lead time for custom Nb targets?

Standard lead time is 3–5 weeks, depending on size, bonding requirements, and order volume.

Q4: What vacuum levels are required for sputtering Nb?

A base pressure of <1×10⁻⁶ Torr is recommended, with working pressures around 2–10 mTorr for stable deposition.

Q5: Does Nb react with oxygen?

Yes. Niobium readily forms niobium oxide (Nb₂O₅), useful for optical and dielectric films. Control of oxygen flow is key in reactive sputtering.

Q6: Are rotary targets compatible with standard sputtering systems?

Most rotary sputtering systems support cylindrical targets. TFM provides customizable dimensions to ensure compatibility.

Q7: Is Nb suitable for multilayer coatings?

Absolutely. Niobium is often used in multilayer stacks due to its adhesion properties and compatibility with other materials like Si, Ti, or Ta.

Q8: What is the difference between 99.95% and 99.995% Nb?

Higher purity levels reduce contamination in films, critical for semiconductors. The selection depends on application precision.

Q9: Can I use Nb rotary targets for reactive sputtering?

Yes, especially for producing NbOx or NbN films. TFM can offer pre-conditioned targets for these applications.

Q10: What backing tube materials are used?

Common backing tubes include oxygen-free copper (OFHC Cu) and 316L stainless steel, depending on thermal conductivity needs.

Conclusion

Niobium (Nb) rotary sputtering targets play a pivotal role in the modern thin film landscape—supporting innovation in semiconductors, optics, energy, and superconductivity. With excellent physical properties, high deposition rates, and long target lifetimes, they are a preferred choice for high-throughput, large-area, and precision coatings.

TFM (Thin Film Materials) is committed to delivering high-purity, dimensionally accurate, and performance-optimized niobium rotary sputtering targets tailored to your specific deposition needs. Whether you’re working on cutting-edge research or industrial production, TFM offers the expertise, quality, and reliability you can trust.

For technical support, custom quotes, or bulk orders, contact TFM’s engineering team today.