Introduction

In cutting-edge industries where vacuum purity, chemical resistance, and extreme temperatures are standard, traditional valve technologies often fall short. The use of elastomers or polymers in conventional valves introduces unacceptable risks: outgassing, material degradation, seal failure, and contamination. In response to these limitations, All-Metal Valves have become the preferred solution for systems operating in ultra-high vacuum (UHV), high-radiation fields, and aggressive chemical processes.

At TFM (Thin Film Materials), we recognize the critical importance of material purity, leak integrity, and mechanical durability. Our selection of all-metal valves is engineered to support high-demand sectors including semiconductor fabrication, space systems, and vacuum thin film deposition.

What Are All-Metal Valves?

An All-Metal Valve is a precision-engineered flow control component composed exclusively of metallic elements—this includes the body, bonnet, sealing elements, actuator interface, and internal flow structures. These valves are constructed without any elastomers, polymers, or soft sealing materials, making them uniquely suited for extreme conditions.

These valves operate on metal-to-metal sealing principles, leveraging lapped or precision-machined surfaces to ensure leak-tight closures even under dynamic thermal cycling, radiation exposure, or ultra-high vacuum levels. They are engineered to function across a broad range of temperatures (from cryogenic levels near absolute zero to over 600°C), high pressures, and chemically harsh environments.

Design and Construction Details

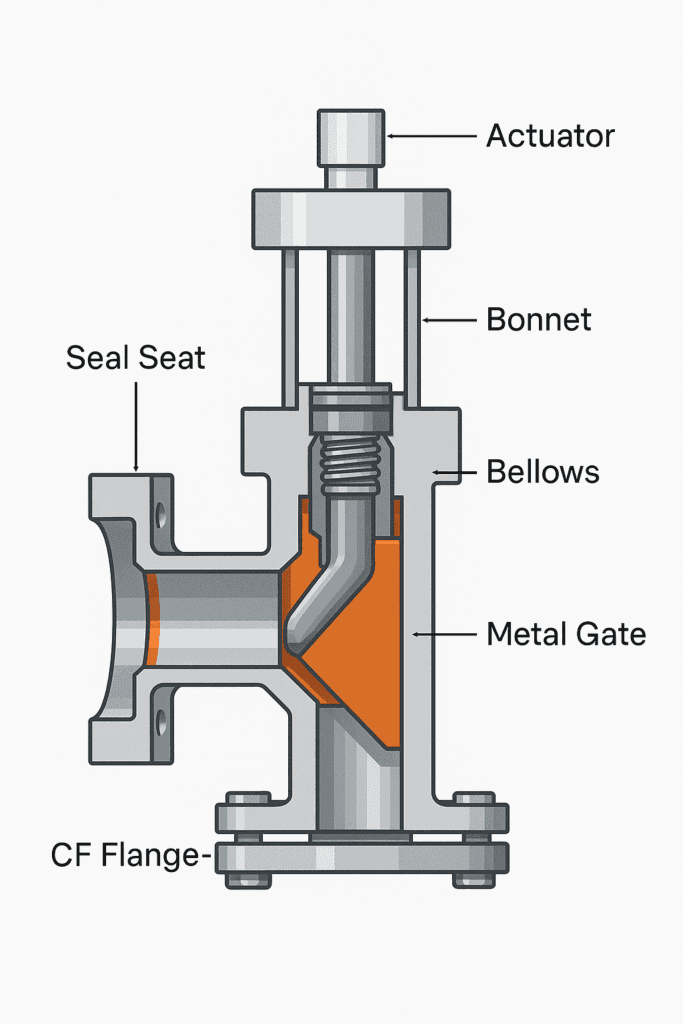

The performance of an all-metal valve hinges on several critical design elements:

● Valve Body and Bonnet

Typically machined from 304L or 316L stainless steel, or in some cases high-performance alloys like Inconel, Hastelloy, or titanium, depending on corrosion and temperature requirements.

● Sealing Surface Geometry

These valves utilize advanced seal geometries such as:

- Knife-edge flanges (common in CF flange systems)

- Polished conical seats (used in globe and gate valves)

- Flat lapped surfaces (for disc-style sealing)

● Actuation Systems

All-metal valves may be manually operated or connected to pneumatic or electric actuators. TFM offers options for both linear and rotary actuators, compatible with cleanroom environments or hazardous duty conditions.

● Bellows Seal

Many UHV-compatible valves incorporate metal bellows to isolate the actuator mechanism from the process chamber. These bellows are typically made of formed or welded stainless steel to provide flexibility and long cycle life under repeated thermal or mechanical stress.

● Bakeability

Unlike plastic or PTFE-lined valves, all-metal valves are bakeable to 250–450°C, making them ideal for in-situ system cleaning and vacuum conditioning.

Advantages of All-Metal Valves

The specialized design of all-metal valves provides several unmatched advantages:

| Feature | Performance Benefit |

|---|---|

| No Outgassing | Ideal for UHV and analytical systems |

| Radiation Resistant | Suited for nuclear and particle physics |

| Chemical Durability | Can handle reactive or corrosive gases |

| Wide Temperature Range | Operates from -270°C to 600°C |

| Leak Tightness | Achieves <1×10⁻¹⁰ mbar·L/s leak rates |

| Longevity | Designed for decades of service with minimal maintenance |

Types of All-Metal Valves Offered by TFM

TFM supplies a range of standardized and custom-configurable all-metal valve types, including:

1. All-Metal Gate Valves

These valves are perfect for isolating vacuum chambers or load-lock ports. A flat or wedge-shaped metal gate is pressed tightly against the valve seat to provide a high-integrity seal.

2. All-Metal Angle Valves

A popular option for vacuum system layout optimization. The 90-degree flow path reduces footprint while ensuring low pressure drop and excellent cleanliness.

3. All-Metal Globe Valves

Enable precise throttling of gas flows. The globe-style body and stem motion allow for fine adjustment of conductance, ideal in mass spectrometry or leak testing systems.

4. All-Metal Butterfly Valves

Suited for high-conductance lines requiring fast on/off control. The metal disc rotates on a central shaft, supported by precision metal seats.

5. All-Metal Ball Valves

Highly durable valves for quick shut-off and flow control. TFM’s all-metal ball valves are used in cryogenic lines and corrosive chemical transport.

Industrial and Research Applications

TFM all-metal valves support a wide range of scientific and industrial applications where contamination control, safety, and mechanical integrity are critical:

● Ultra-High Vacuum (UHV) Systems

Used in molecular beam epitaxy (MBE), surface science, electron spectroscopy, and ion implantation chambers. All-metal valves allow system bake-out without material degradation.

● Semiconductor Equipment

Including plasma etching, atomic layer deposition (ALD), and lithography tools where particle control and vacuum purity are non-negotiable.

● Aerospace and Cryogenics

Liquid hydrogen, helium, or oxygen fuel lines require cryo-compatible, metal-sealed valves to prevent embrittlement and outgassing.

● Nuclear Science and Fusion Research

From particle accelerators to nuclear reactors, all-metal valves operate reliably in high-radiation and vacuum environments.

● Chemical and Petrochemical Processing

Valves made from Hastelloy, Inconel, or Monel resist harsh chemicals such as chlorine, HF, or halogenated gases.

● Synchrotrons and Neutron Sources

Where radiation, thermal cycling, and vacuum are simultaneously present, metal-only construction ensures performance.

Historical Context and Development

All-metal valves emerged during the Cold War era as part of the development of nuclear research infrastructure and space exploration. At the time, vacuum systems needed components that could withstand bake-out, radiation, and thermal cycling over long mission durations.

Early designs were extremely bulky and manually operated, but today’s advancements in CNC machining, laser welding, and materials science allow for lightweight, compact all-metal valves with precision leak tightness and long service life.

TFM’s product line benefits from decades of vacuum science evolution and is built to comply with modern standards like ISO 2861 (KF/ISO flanges) and ISO 3669 (CF flanges).

Custom Engineering and Value-Added Services from TFM

At TFM, we go beyond standard catalogs. We support clients with:

- Custom flange configurations (CF, KF, ISO, ANSI)

- Material substitution for extreme corrosion resistance (e.g., replacing stainless steel with tantalum or Monel)

- Custom pressure and temperature ratings

- Cleanroom pre-conditioning

- Welded integration with tube assemblies or chamber ports

- Leak testing and certification

Our valves are vacuum-tested, helium leak-checked, and thoroughly inspected to meet ultra-demanding system integration requirements.

Frequently Asked Questions (Extended)

Q1: Can all-metal valves handle toxic gases?

A: Yes. With appropriate materials (e.g., Hastelloy or Monel), they are ideal for toxic and reactive gas environments.

Q2: Can TFM provide all-metal valves with pneumatic actuators?

A: Absolutely. We offer actuator packages suitable for cleanrooms, corrosive environments, or automated control.

Q3: Are all-metal valves compatible with ISO-KF flanges?

A: TFM provides valves for both KF and CF flange systems. Custom flange transitions are also available.

Q4: How often should I service an all-metal valve?

A: Under UHV conditions and correct installation, many valves operate for over 10 years with minimal servicing. However, periodic cleaning and inspection is recommended in aggressive gas environments.

Q5: Can I bake out an all-metal valve to 450°C?

A: Yes. TFM’s valves are bakeable to 450°C, provided proper installation and flange hardware are used.

Q6: What is the delivery time for custom all-metal valves?

A: Standard models may ship in 5–7 days. Custom configurations require 3–5 weeks depending on complexity.

Q7: How are valves leak-tested?

A: Each TFM all-metal valve is helium leak-tested to <1×10⁻¹⁰ mbar·L/s using a calibrated mass spectrometer.

Q8: Do you offer CAD drawings or STEP files?

A: Yes, 2D and 3D files are available upon request to support system integration.

Q9: Can I order welded assemblies with multiple valves and fittings?

A: Definitely. TFM provides welded UHV assemblies including valves, tubing, crosses, and flanges—all helium leak tested.

Q10: Do your all-metal valves meet ISO or ASTM standards?

A: Yes, our valves conform to ISO 3669, ASTM B446, and related specifications depending on material and application.

Conclusion

All-Metal Valves represent the pinnacle of durability, cleanliness, and engineering precision in flow control devices. Whether your system is operating in the harsh vacuum of space, the cryogenic temperature of liquid helium, or the corrosive atmosphere of a plasma reactor, these valves offer unmatched performance and peace of mind.

At TFM, we are proud to support research institutions, aerospace innovators, semiconductor manufacturers, and advanced materials laboratories with dependable all-metal valve solutions. Backed by engineering expertise and strict quality control, our valves ensure your systems perform without compromise.

Explore our full catalog today or contact our vacuum engineering team for tailored solutions.

1 thought on “All-Metal Valves: High-Performance Flow Control for UHV and Extreme Environments”

This is the right blog for anyone who wants to find out about this topic. You realize so much its almost hard to argue with you (not that I actually would want…HaHa). You definitely put a new spin on a topic thats been written about for years. Great stuff, just great!