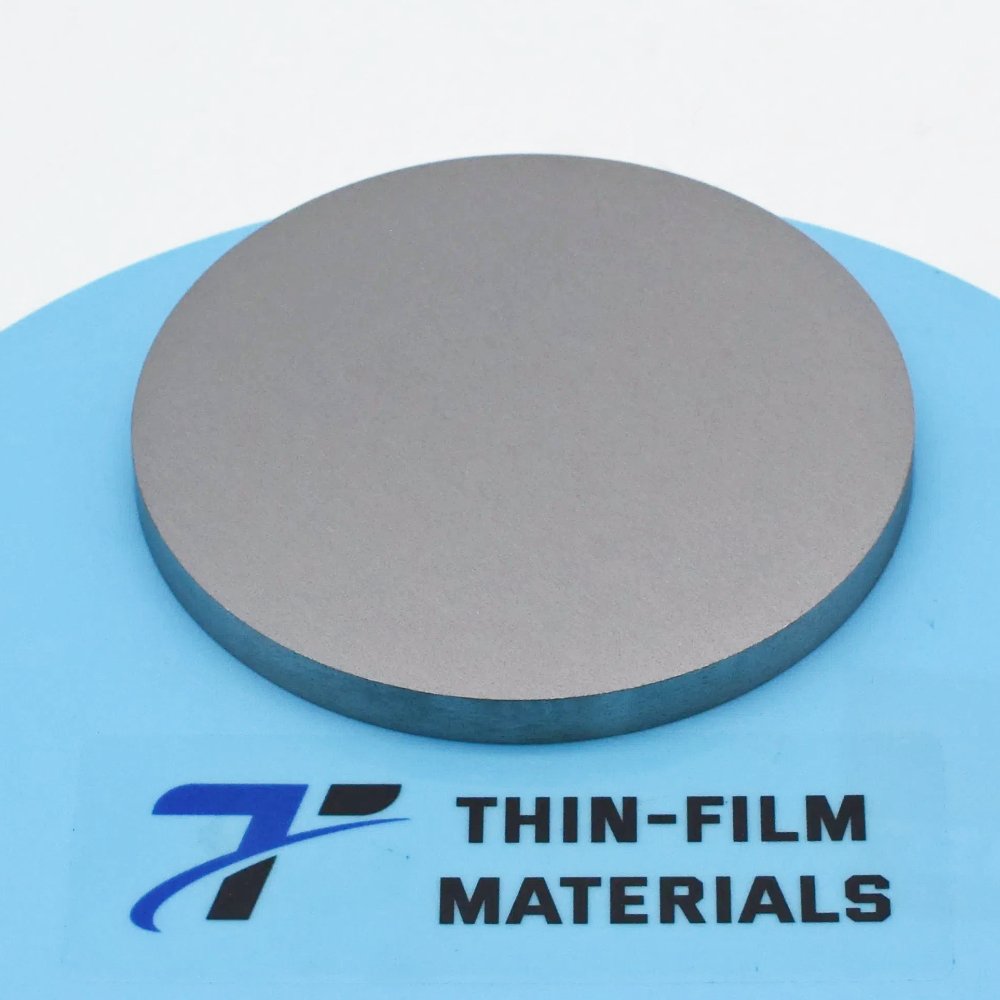

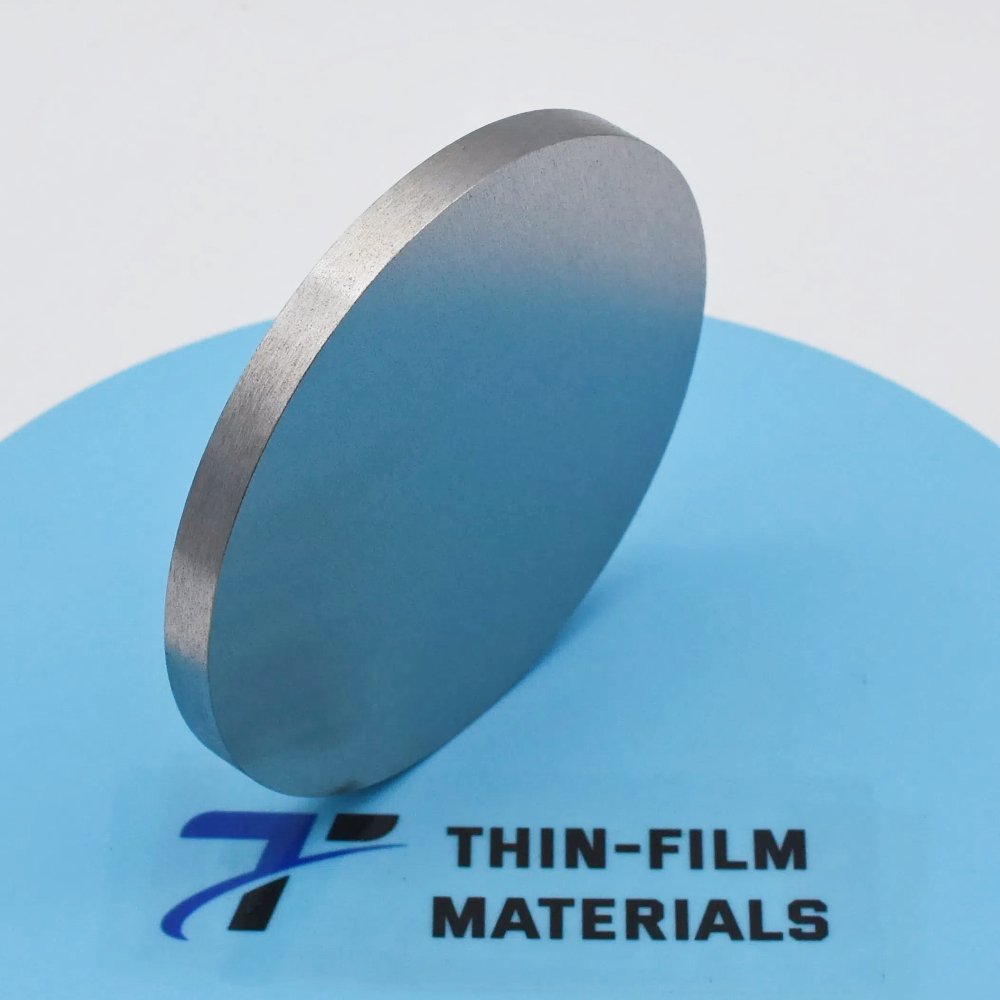

When your sputtering process demands extreme hardness, outstanding thermal stability, and superior film performance, ordinary targets simply won’t cut it. That’s where refractory boride targets like Tungsten Nickel Boride (WNiB) and Tungsten Zirconium Boride (WZrB) step in. These advanced sputtering materials are engineered to thrive under punishing deposition conditions, ensuring you get high-quality thin films every single time.

What Are WNiB and WZrB Sputtering Targets?

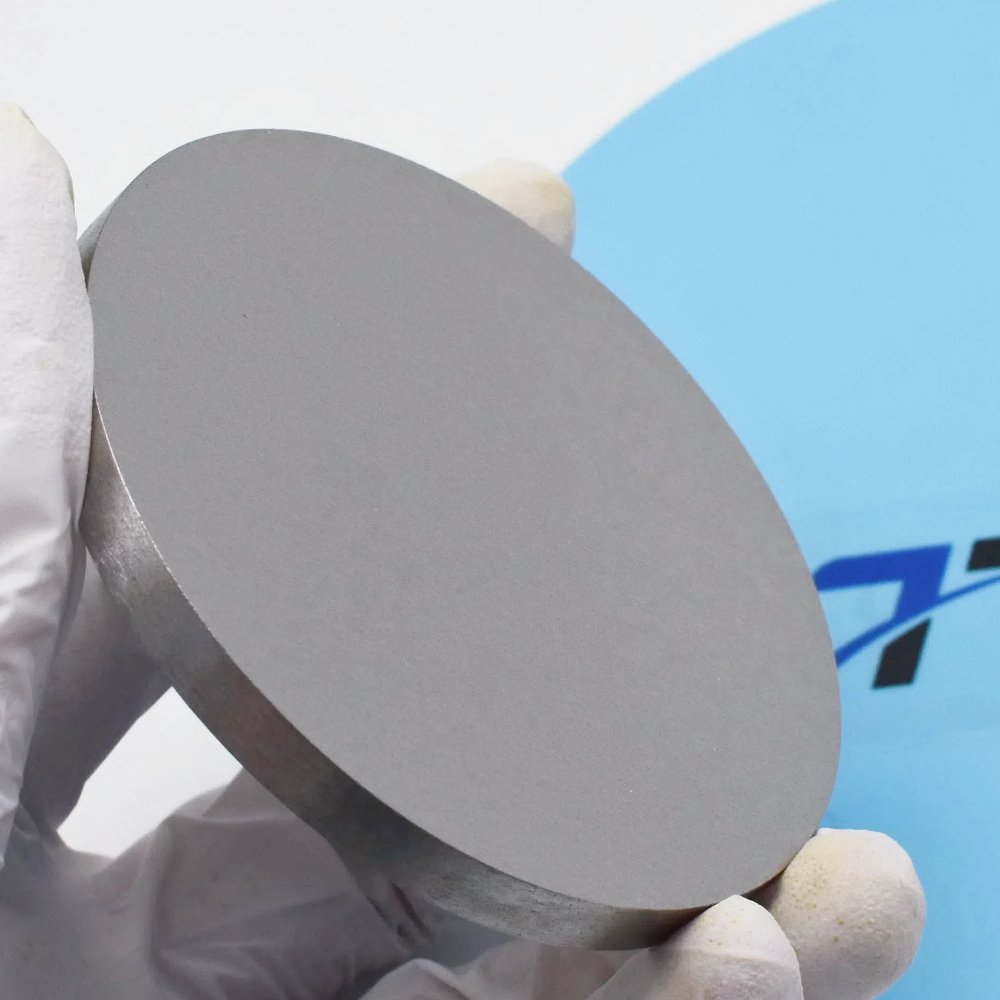

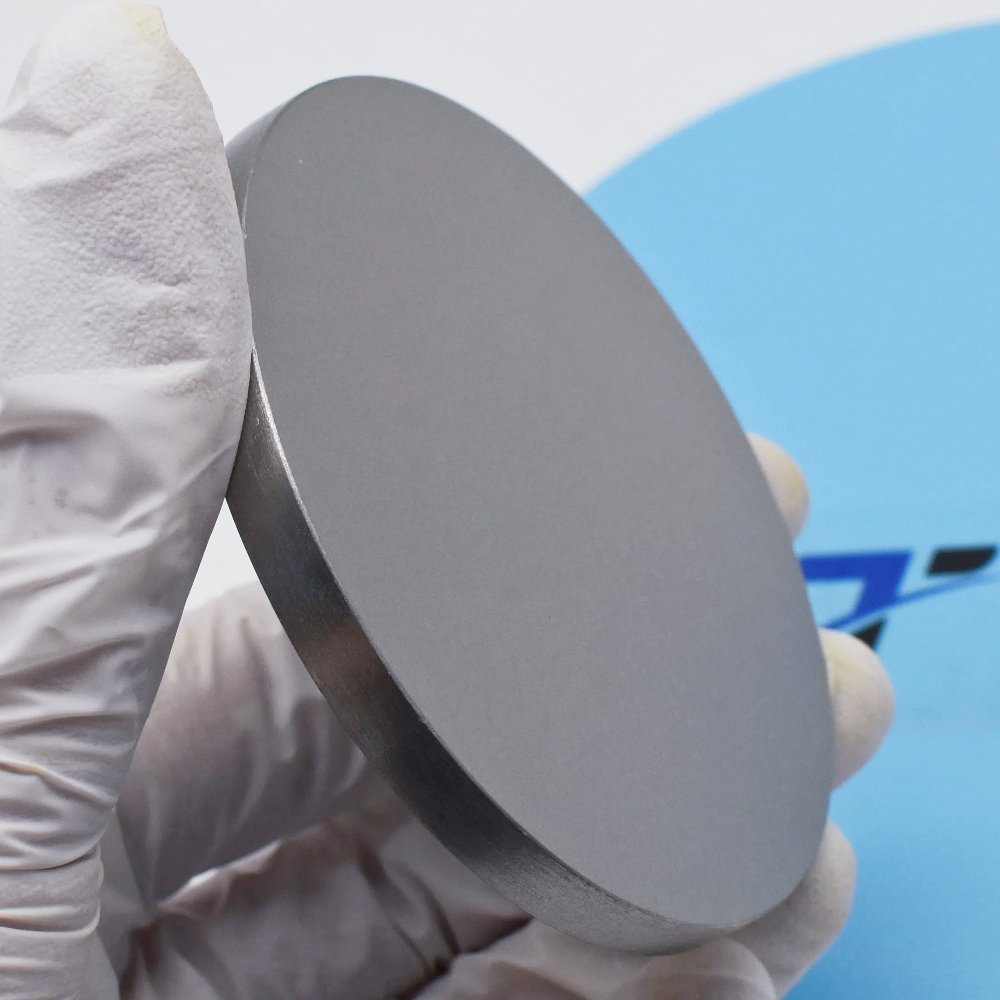

WNiB (Tungsten–Nickel–Boron) combines tungsten’s ultra-high density with nickel’s ductility and boron’s hardness. The result? A target material that delivers exceptional wear resistance, toughness, and consistent film adhesion. It’s a preferred choice in thin-film deposition where durability and precision are paramount.

WZrB (Tungsten–Zirconium–Boron) adds zirconium to the tungsten-boride base, enhancing corrosion resistance and thermal performance. This makes it ideal for coating applications in harsh chemical environments, high-temperature aerospace components, and next-gen semiconductor manufacturing.

Both targets are available in high-purity grades (≥99.5%) and can be supplied as discs, rectangular plates, step targets, or rotary forms to fit DC magnetron sputtering or RF sputtering systems.

Key Performance Advantages

- Extreme Temperature Stability: With melting points exceeding 2,800°C, both WNiB and WZrB remain stable during high-energy deposition.

- High Hardness & Wear Resistance: Extended operational life reduces downtime and replacement costs.

- Excellent Film Adhesion: Produces dense, uniform coatings with minimal defects.

- Corrosion Resistance: WZrB offers superior protection in chemically aggressive environments.

- Versatility: Compatible with reactive sputtering (e.g., N₂, O₂) to create boride, nitride, or oxide films.

Applications Across Industries

- Semiconductors: Barrier layers, interconnects, MEMS devices.

- Aerospace: Thermal protection coatings for turbine blades, rocket nozzles.

- Optics: Anti-reflective, scratch-resistant layers.

- Energy: Coatings for solar cells, fuel cells, and battery components.

- Tooling: Hard protective coatings for cutting tools, molds, and dies.

WNiB vs. WZrB – Quick Comparison

| Property | WNiB | WZrB |

|---|---|---|

| Density | ~18.5 g/cc | ~17.0 g/cc |

| Corrosion Resistance | Good | Excellent |

| Thermal Conductivity | High | Moderate |

| Hardness | Very high | High |

| Best Use Case | Wear-resistant films | Corrosion-resistant films |

Why TFM?

TFM has over a decade of experience producing custom-engineered sputtering targets for semiconductor fabs, aerospace OEMs, and R&D institutions worldwide. Our ISO 9001-certified manufacturing ensures consistent quality, and our ability to customize composition, size, and bonding methods means you get a target tailored exactly to your process.

We ship globally — serving clients in North America, Europe, Japan, Israel, and Australia — and provide full technical consultation to help you choose the right target for your application.

FAQs

Q: Can WNiB and WZrB be used in reactive sputtering?

Yes. They work with reactive gases like nitrogen or oxygen to deposit boride, nitride, or oxide films.

Q: What bonding options are available?

We offer indium bonding and elastomer bonding for improved heat transfer and target stability.

Q: How is purity verified?

Every batch undergoes ICP-MS and XRF testing to maintain strict impurity control.

Ready to enhance your thin-film deposition process with WNiB or WZrB targets?

📩 Contact TFM at sales@thinfilmmaterials.com for a technical consultation or request a quote.