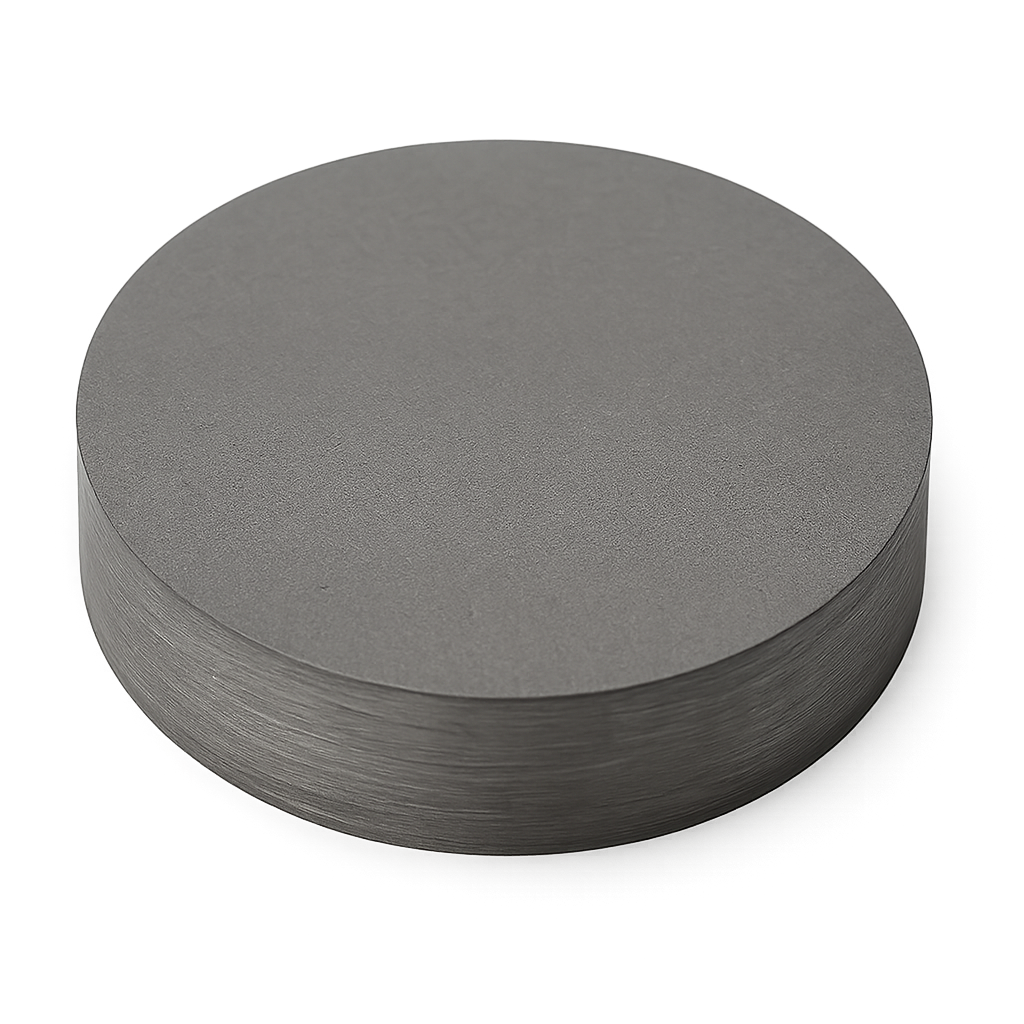

Introduction to Molybdenum Aluminum Boride (MoAlB₂) Sputtering Target

The Molybdenum Aluminum Boride (MoAlB₂) Sputtering Target is an advanced ceramic–metal composite material used for thin-film deposition. Incorporating molybdenum (Mo), aluminum (Al), and boron (B), this compound belongs to the boride family, combining the thermal and mechanical stability of molybdenum, the oxidation resistance of aluminum, and the extreme hardness of boron. MoAlB₂ is particularly valued for its multifunctional performance in demanding thin-film applications.

Material Structure and Properties

Crystal Structure: MoAlB₂ forms a layered boride structure with strong metal–boron and boron–boron bonds, providing superior hardness and stability.

Refractory Behavior: Molybdenum contributes excellent high-temperature stability, high melting point (2623 °C for Mo), and robust mechanical strength.

Oxidation Resistance: Aluminum forms protective alumina (Al₂O₃) layers at elevated temperatures, improving corrosion resistance.

High Hardness & Wear Resistance: Boron bonding contributes to extreme hardness and enhanced wear performance of the films.

Key Features of MoAlB₂ Sputtering Target

High Density & Purity: Produced with densities above 95% of theoretical and purities of 99.5–99.9%, ensuring clean and efficient sputtering.

Stable Sputtering Performance: Resistant to cracking and spalling, with consistent deposition rates.

Film Quality: Enables uniform, dense, and well-adhered thin films.

Deposition Flexibility: Suitable for both RF and DC magnetron sputtering as well as pulsed laser deposition (PLD).

Applications

The MoAlB₂ sputtering target finds application in a wide range of advanced industrial and research sectors:

Protective Hard Coatings – Thin, ultra-hard films for cutting tools, machining components, and wear parts.

Aerospace & Automotive – Oxidation-resistant, high-temperature coatings for turbines, pistons, and structural components.

Electronics & Semiconductors – Barrier layers, conductive interconnects, and protective coatings.

Energy & Nuclear Fields – Radiation- and corrosion-resistant films for demanding environments.

Research & Development – Exploration of new boride-based thin films with multifunctional mechanical, electrical, and optical properties.

Fabrication & Deposition

Manufacturing: MoAlB₂ targets are typically produced via solid-state sintering, hot-pressing, or spark plasma sintering (SPS) methods to achieve dense and durable targets.

Deposition Characteristics: Films sputtered from MoAlB₂ exhibit high hardness, excellent thermal stability, chemical resistance, and smooth morphology.

Compatibility: Performs well with RF/DC magnetron sputtering systems and PLD setups.

Reviews

There are no reviews yet.