Cerium(IV) Oxide Powder (CeO₂)

Introduction

Cerium(IV) Oxide Powder (CeO₂), commonly known as ceria, is a high-performance rare-earth oxide with remarkable redox properties, chemical stability, and optical transparency in the visible and infrared range. Its unique ability to shift between Ce³⁺ and Ce⁴⁺ oxidation states makes it widely applicable in catalysts, polishing compounds, fuel cells, and advanced coatings.

Detailed Description

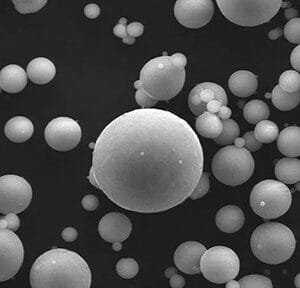

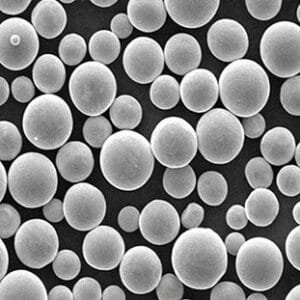

Cerium(IV) Oxide appears as a pale-yellow to white fine powder. With a high melting point (~2,400 °C) and density (~7.13 g/cm³), CeO₂ is extremely stable and versatile. Available in various grades from 99.9% (3N) to 99.999% (5N) purity, the powder can be tailored for applications requiring high chemical purity and uniform particle size distribution.

Key features include:

Excellent oxygen storage and release capacity, making it indispensable in catalytic converters.

High hardness and fine particle size, ideal for precision glass and semiconductor polishing.

Good ionic conductivity, used in solid oxide fuel cells (SOFCs) and oxygen sensors.

UV absorption capability, allowing it to function in protective coatings.

Applications

Cerium(IV) Oxide Powder is widely used in:

Catalysts: Automotive three-way catalysts, petrochemical processes, and environmental protection.

Polishing materials: Precision glass polishing (lenses, mirrors, LCD panels, silicon wafers).

Energy devices: Solid oxide fuel cells and oxygen permeation membranes.

UV protection: Coatings and additives in glass and ceramics.

Electronics: Dielectric layers and barrier materials in microelectronics.

Technical Parameters

| Parameter | Typical Value / Range | Importance |

|---|---|---|

| Purity | 99.9% – 99.999% | Ensures reliable performance in optics and electronics |

| Particle Size | 50 nm – 5 µm | Smaller sizes improve polishing efficiency |

| Appearance | Pale yellow to white powder | Color variation indicates oxidation state |

| Melting Point | ~2,400 °C | High stability for refractory use |

| Density | ~7.13 g/cm³ | Important for ceramics and coatings |

Comparison with Related Materials

| Material | Key Advantage | Typical Application |

|---|---|---|

| Cerium Oxide (CeO₂) | Oxygen storage, polishing ability | Catalysts, polishing |

| Zirconium Oxide (ZrO₂) | High strength, fracture toughness | Structural ceramics |

| Titanium Oxide (TiO₂) | Strong UV absorption, photocatalysis | Pigments, photocatalysts |

FAQ

| Question | Answer |

|---|---|

| What is the color of CeO₂ powder? | Usually pale yellow to white, depending on particle size and purity. |

| Can CeO₂ be used in catalysts? | Yes, it is a key oxygen storage component in automotive and industrial catalysts. |

| Is nanoscale CeO₂ available? | Yes, nano-grade ceria (10–100 nm) is widely used in polishing and catalysis. |

| How is it packaged? | Vacuum-sealed bottles or bags, with larger volumes in export-safe drums. |

| Which industries use CeO₂ the most? | Automotive, optics, electronics, energy, and ceramics. |

Packaging

Cerium(IV) Oxide Powder is carefully vacuum-packed in moisture-proof containers to maintain purity. For industrial-scale orders, sealed drums or cartons with cushioning ensure safe transport and long-term stability.

Conclusion

Cerium(IV) Oxide Powder (CeO₂) is a critical material that bridges energy, optics, catalysis, and electronics. With its excellent redox and polishing properties, it remains indispensable across industries from automotive to semiconductor manufacturing.

For detailed specifications and a quotation, please contact us at [sales@thinfilmmaterials.com].

Reviews

There are no reviews yet.