Magnesium Oxide Powder (MgO)

Introduction

Magnesium Oxide Powder (MgO), also known as magnesia, is a widely used inorganic material known for its excellent thermal stability, high melting point, and electrical insulation properties. It is one of the most important ceramic and refractory materials, playing a crucial role in metallurgy, construction, electronics, and environmental protection.

Detailed Description

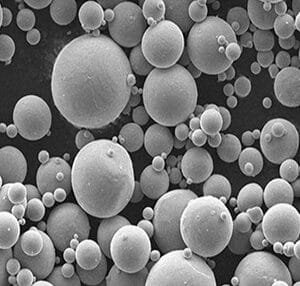

Magnesium Oxide is a fine, white powder with a melting point of ~2,852 °C and density of ~3.58 g/cm³. It is commonly produced in purities from 99% to 99.99%, with particle sizes ranging from nanoscale to several microns depending on the application.

Key features include:

High refractoriness: Resistant to extremely high temperatures, making it suitable for refractory bricks and furnace linings.

Electrical insulation: Excellent dielectric properties, used in heating elements and insulating materials.

Chemical stability: Resistant to corrosion and chemical attack, ensuring durability.

Reactivity: Active MgO grades can act as adsorbents and catalysts in environmental applications.

Applications

Magnesium Oxide Powder is widely used in:

Refractory materials: Crucibles, furnace linings, and bricks for steelmaking and glass industries.

Electronics: Insulation in electrical heating elements and ceramic substrates.

Construction: Cement, fireproof boards, and insulation panels.

Environmental: Absorbent for pollutants, wastewater treatment, and flue gas desulfurization.

Healthcare: As a supplement and antacid in the pharmaceutical industry.

Technical Parameters

| Parameter | Typical Value / Range | Importance |

|---|---|---|

| Purity | 99% – 99.99% | Determines performance in electronics and refractories |

| Particle Size | 50 nm – 10 µm | Nano-sized powders improve reactivity and sintering |

| Appearance | White crystalline powder | High purity material consistency |

| Melting Point | ~2,852 °C | Essential for high-temperature refractory use |

| Density | ~3.58 g/cm³ | Suitable for ceramics and construction materials |

Comparison with Related Materials

| Material | Key Advantage | Typical Application |

|---|---|---|

| Magnesium Oxide (MgO) | High melting point, insulation | Refractories, electronics |

| Aluminum Oxide (Al₂O₃) | High hardness, wear resistance | Abrasives, ceramics |

| Calcium Oxide (CaO) | Strong alkalinity, reactivity | Cement, desulfurization |

FAQ

| Question | Answer |

|---|---|

| What purity grades are available? | 99%, 99.9%, and 99.99% depending on the application. |

| Can MgO withstand high heat? | Yes, it has a melting point above 2,850 °C, ideal for refractory use. |

| Is MgO safe for pharmaceuticals? | Yes, high-purity grades are used in supplements and antacids. |

| How is MgO packaged? | Vacuum-sealed containers for lab use; bulk supplied in lined bags or drums. |

| Which industries benefit most? | Metallurgy, electronics, construction, healthcare, and environmental sectors. |

Packaging

Magnesium Oxide Powder is securely sealed in moisture-proof bags or bottles for laboratory use. For industrial applications, it is shipped in multi-layered sacks or export-grade drums to ensure safety and prevent contamination.

Conclusion

Magnesium Oxide Powder (MgO) is an essential multifunctional material combining refractory strength, electrical insulation, and chemical stability. From steelmaking to pharmaceuticals, it supports critical industries worldwide.

For detailed specifications and a quotation, please contact us at [sales@thinfilmmaterials.com].

Reviews

There are no reviews yet.