Introduction

Dysprosium Iron Garnet (Dy₃Fe₅O₁₂, abbreviated as DyIG) is a rare-earth iron garnet material that has recently gained renewed attention in the field of magneto-optical and spintronic technologies. As a member of the broader R₃Fe₅O₁₂ garnet family, where R represents a rare-earth ion, DyIG exhibits a unique balance between magnetic anisotropy, optical transparency, and Faraday rotation.

While Yttrium Iron Garnet (YIG) remains the most extensively studied material in this class, Dysprosium Iron Garnet offers several distinctive advantages—particularly its enhanced magneto-optical performance at low temperatures and its suitability for cryogenic optical and spintronic devices.

This article explores the synthesis, structural characteristics, optical and magnetic properties, and the expanding range of applications for DyIG thin films, emphasizing their relevance in modern magneto-optical isolators, sensors, and cryogenic systems.

What is Dysprosium Iron Garnet (DyIG)?

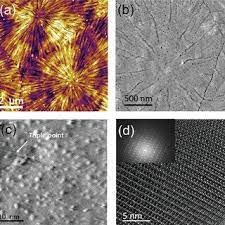

DyIG is a ferrimagnetic oxide with a general chemical formula R₃Fe₅O₁₂, where Dysprosium (Dy³⁺) occupies the dodecahedral lattice site in the cubic garnet structure (space group Ia3d).

Its unique magnetic properties arise from the antiparallel coupling between the Fe³⁺ ions at octahedral and tetrahedral sites, and the Dy³⁺ ions in the dodecahedral positions.

Key Material Features

- Crystal structure: Cubic garnet

- Saturation magnetization: ~1450 G

- Curie temperature: ~220 K

- Refractive index: 2.3–2.4

- Faraday rotation: Strong wavelength dependence, typically 0.8–1.2°/μm at 633 nm

The strong spin–orbit coupling of Dysprosium ions contributes to the large magneto-optical response, particularly at cryogenic temperatures where Dy³⁺ moments dominate the net magnetization. This makes DyIG highly valuable for research in low-temperature magneto-optic systems and quantum photonics.

Fabrication of DyIG Thin Films

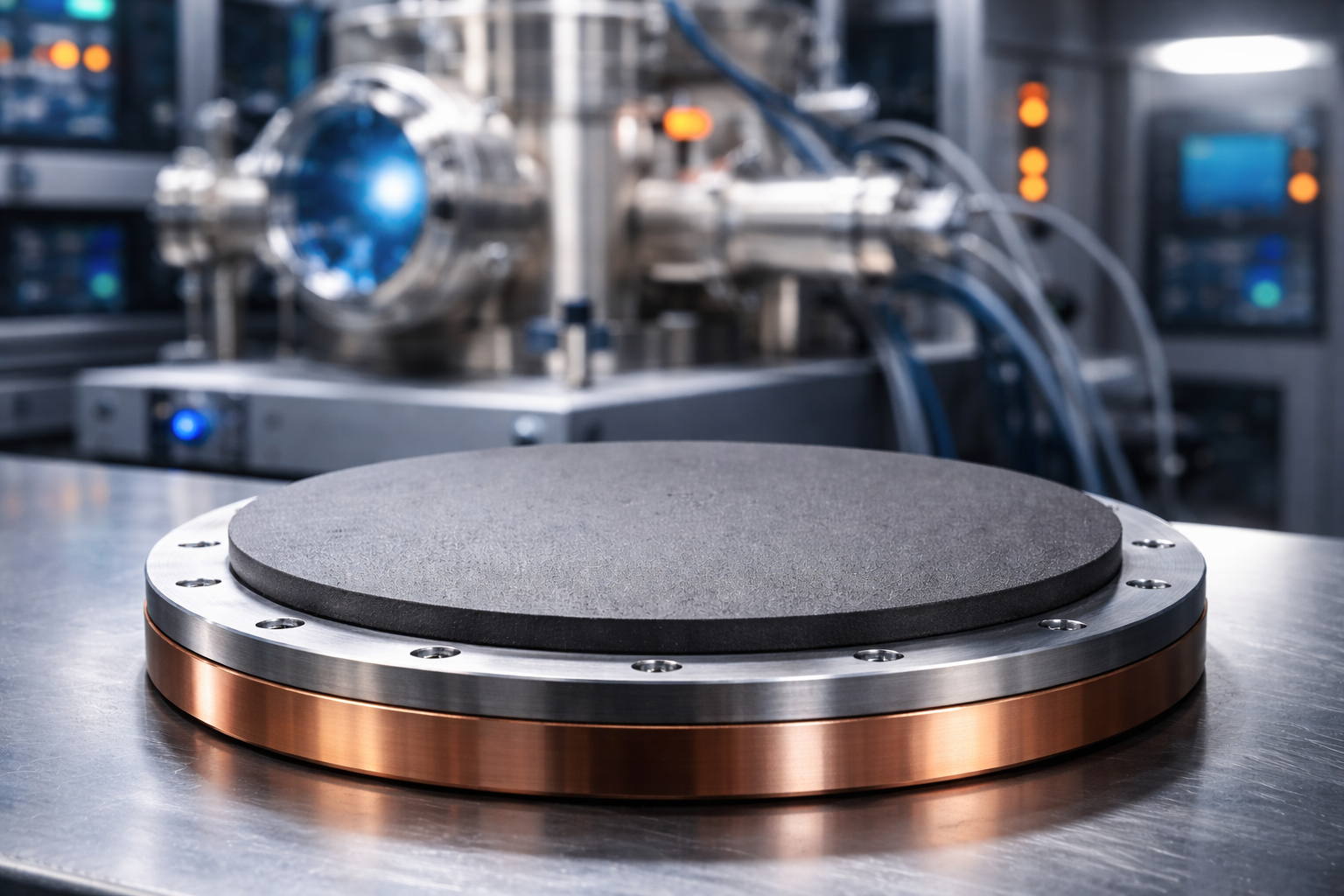

1. Sputtering Target Preparation

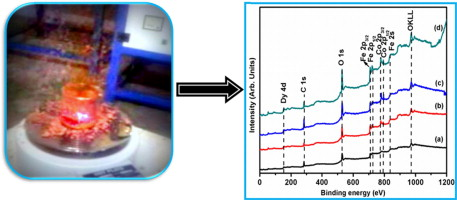

High-quality Dysprosium Iron Garnet sputtering targets are typically produced via solid-state reaction between Dy₂O₃ and Fe₂O₃ powders.

The mixed powders are calcined and sintered at 1250–1400 °C in an oxygen-controlled environment to ensure:

- High phase purity (>99.9%)

- Uniform grain size distribution

- Density exceeding 97% of the theoretical value

For industrial-scale deposition, the targets are bonded to copper or molybdenum backing plates to improve heat dissipation and mechanical stability during RF magnetron sputtering.

TFM supplies DyIG sputtering targets in diameters ranging from 1 to 3 inches, with customizable thickness, purity, and bonding configurations to suit different sputtering systems.

2. Deposition Techniques

DyIG thin films can be deposited using several techniques, depending on the desired structure and substrate compatibility:

- RF Magnetron Sputtering – offers uniform large-area films with precise stoichiometry control.

- Pulsed Laser Deposition (PLD) – enables epitaxial film growth on garnet or perovskite substrates.

- Metal-Organic Chemical Vapor Deposition (MOCVD) – suitable for multilayer optical coatings with fine compositional control.

Post-deposition annealing between 650–850 °C in an oxygen-rich atmosphere is crucial for achieving the fully crystallized garnet phase and optimal magnetic ordering.

Magneto-Optical Properties

The hallmark of DyIG lies in its magneto-optical activity, particularly its large Faraday rotation—the rotation of polarized light as it passes through a magnetized material.

| Property | Typical Value | Significance |

|---|---|---|

| Faraday Rotation | 0.8–1.2°/μm @ 633 nm | Determines isolator and modulator efficiency |

| Coercivity | 200–500 Oe | Influences magnetic switching speed |

| Refractive Index | 2.3–2.4 | Affects optical waveguide design |

| Curie Temperature | 220 K | Enables low-temperature operation |

| Magnetostriction | Negative | Helps minimize stress in multilayer films |

DyIG thin films demonstrate strong Faraday rotation near visible wavelengths and a high degree of optical transparency in the near-infrared range, making them particularly effective in cryogenic optical isolators and magneto-optical waveguides.

Applications of DyIG Thin Films

1. Magneto-Optical Isolators and Circulators

The large Faraday rotation and low optical loss make DyIG ideal for optical isolators, which prevent back reflections in laser systems. These isolators are essential components in fiber-optic communications and low-temperature quantum optics setups.

2. Magnetic Field and Current Sensors

DyIG’s linear Faraday effect can be used for non-contact magnetic sensing. Its high sensitivity enables the detection of weak magnetic fields or current changes in cryogenic and precision instrumentation.

3. Spintronic and Magnonic Devices

In combination with heavy metals such as platinum or tantalum, DyIG thin films can support spin pumping, spin Hall effects, and spin Seebeck phenomena—providing a promising route toward low-damping spintronic devices.

4. Cryogenic Optical Modulators

Due to its relatively low Curie temperature, DyIG maintains strong magneto-optic activity in cryogenic environments, making it suitable for quantum computing interfaces, photon-based logic circuits, and low-temperature magnetic sensors.

Comparison with Related Garnet Materials

| Material | Faraday Rotation (°/μm @633 nm) | Curie Temperature (K) | Key Advantage |

|---|---|---|---|

| DyIG (Dy₃Fe₅O₁₂) | 0.9 | 220 | Strong magneto-optical activity at low temperatures |

| YIG (Y₃Fe₅O₁₂) | 0.25 | 560 | Low optical loss and high transparency |

| Bi:YIG (Bi₃Y₂Fe₅O₁₂) | 1.5 | 520 | Very high Faraday rotation near-IR region |

| GdIG (Gd₃Fe₅O₁₂) | 0.7 | 285 | Broad magnetic response spectrum |

Among these, DyIG stands out for its cryogenic performance and pronounced anisotropy, enabling new device architectures where conventional YIG fails to perform efficiently.

Technical Parameters of DyIG Sputtering Target

| Parameter | Typical Value / Range | Importance |

|---|---|---|

| Purity | 99.9% (3N) | Ensures film consistency |

| Density | ≥97% theoretical | Improves sputtering yield |

| Diameter | 1–3 inch (custom) | Fits standard sputtering systems |

| Thickness | 3–6 mm | Adjusts deposition rate |

| Bonding | Cu / Mo backing optional | Enhances thermal management |

TFM’s DyIG sputtering targets undergo strict compositional and density control to minimize oxygen vacancy defects and ensure high-quality film growth across various substrates, including GGG, quartz, and sapphire.

Challenges and Research Outlook

Although DyIG offers exceptional magneto-optical characteristics, several challenges remain for its widespread adoption:

- Low Curie Temperature: Limits room-temperature applications, though suitable for cryogenic systems.

- Film Stress and Lattice Mismatch: Cracking may occur due to substrate mismatch; optimized annealing and buffer layers can mitigate this.

- Doping Optimization: Incorporating Bi, Ga, or Gd can enhance Faraday rotation and raise Curie temperature for room-temperature applications.

Ongoing research focuses on DyIG/YIG multilayers, Bi-doped DyIG films, and nanocomposite garnets to extend their operational temperature range and improve magneto-optical efficiency.

Packaging and Handling

Each DyIG sputtering target is individually vacuum-sealed in an inert-gas-filled bag and cushioned within anti-static foam for protection during transport.

TFM ensures all targets are labeled with full traceability data, including batch number, composition, and density verification, ensuring quality and reproducibility for research and production environments.

Conclusion

Dysprosium Iron Garnet (DyIG) thin films represent a fascinating and versatile class of magneto-optical materials. With their high Faraday rotation, strong anisotropy, and low-temperature stability, DyIG films bridge the gap between optical engineering and quantum magnetism.

As research continues into spintronic interfaces and cryogenic optical isolators, DyIG is poised to play a key role in the development of next-generation magneto-optical technologies.

For high-purity DyIG sputtering targets and technical support, contact TFM (Thin Film Materials) at

📧 sales@thinfilmmaterials.com.

Related Applications & Synonyms

Dy₃Fe₅O₁₂, Rare-Earth Iron Garnet, Magneto-Optical Thin Films, Faraday Effect Materials, Spintronic Oxides, Garnet Sputtering Targets, Optical Isolator Films, Cryogenic Sensors, RF Sputtering Materials.