Introduction

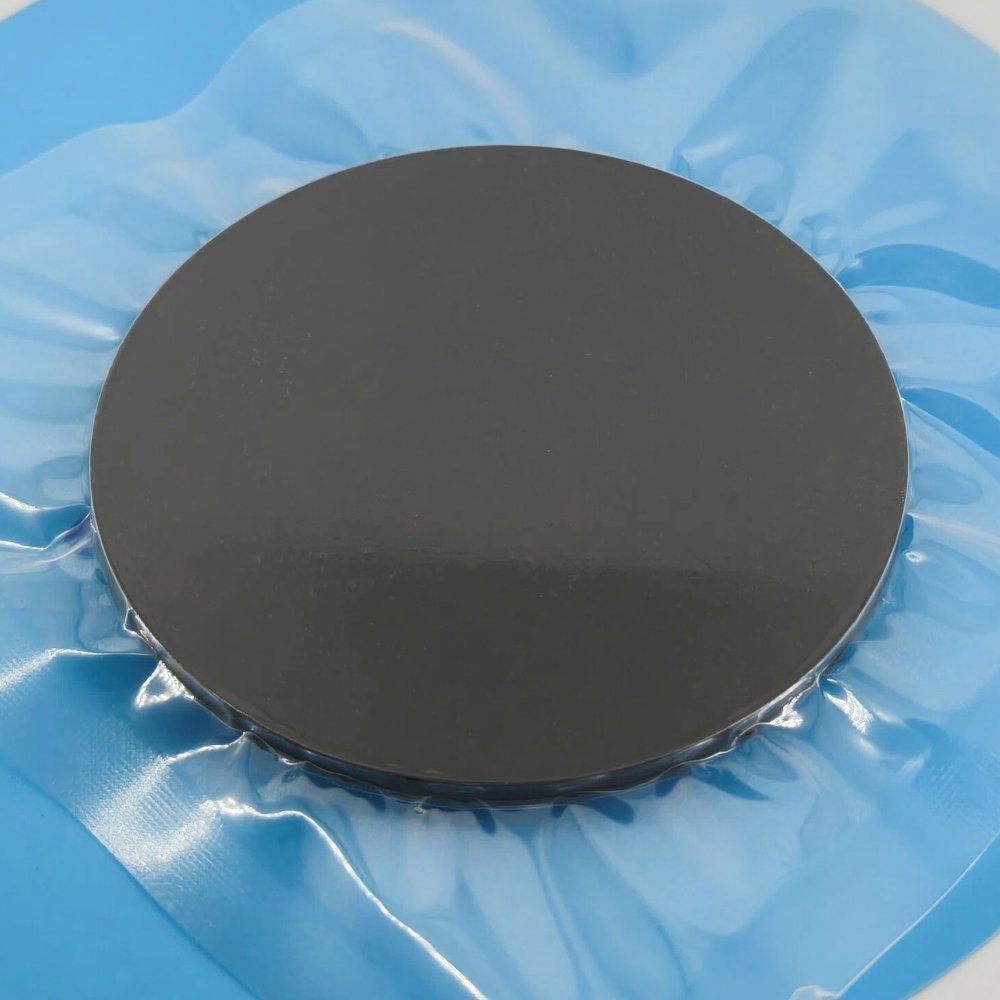

The Aluminum Magnesium Boride (AlMgB₁₄, 1:1:14) Sputtering Target is a high-performance ceramic–metal composite material known for its exceptional hardness, low friction, and thermal stability. These attributes make it an attractive option for next-generation protective coatings, wear-resistant films, and advanced tribological surfaces used in engineering and scientific applications.

Detailed Description

Aluminum Magnesium Boride with a stoichiometric ratio of 1:1:14 is part of the AlMgB₁₄ family—materials recognized for extremely high microhardness and outstanding wear resistance. When fabricated into sputtering targets, the compound delivers films exhibiting strong mechanical stability, high temperature endurance, and reduced friction coefficients.

Our targets are produced using controlled powder synthesis, high-temperature hot pressing, and precision finishing to achieve uniform density and excellent grain structure. This ensures consistent sputtering behavior with minimized particle shedding during deposition. To support high-power PVD processes, optional copper (Cu) or titanium (Ti) backing plates may be applied, improving heat transfer and structural integrity.

Applications

Ultra-hard, low-friction coatings for industrial tooling

Tribological layers for automotive and aerospace components

Mechanical protection films for moving parts and precision assemblies

Research on superhard lightweight ceramic–metal composites

Wear-resistant functional coatings used in sensors and microsystems

Thin-film engineering in mechanical, defense, and electronic applications

Technical Parameters

| Parameter | Typical Value / Range | Importance |

|---|---|---|

| Composition | AlMgB₁₄ (1:1:14) | Stable superhard ceramic–metal composite |

| Purity | 99.5% – 99.9% | Higher purity improves film quality |

| Diameter | 25 – 300 mm (custom) | Fits most commercial sputtering systems |

| Thickness | 3 – 6 mm | Influences sputtering rate and durability |

| Bonding | Cu / Ti backing optional | Enhances cooling and mechanical stability |

| Forms | Disc / rectangular plate | Suitable for planar sputtering setups |

Comparison with Related Materials

| Material | Key Advantage | Typical Application |

|---|---|---|

| AlMgB₁₄ | Extremely high hardness & low friction | Wear-resistant coatings |

| Titanium | Good adhesion and stability | Decorative & functional layers |

| Aluminum | Lightweight and economical | General thin film coatings |

FAQ

| Question | Answer |

|---|---|

| Can the composition be customized? | Yes. Variants within the AlMgB system can be fabricated on request. |

| Do you offer bonded targets? | Yes. Cu or Ti backing plates are available for high-power sputtering. |

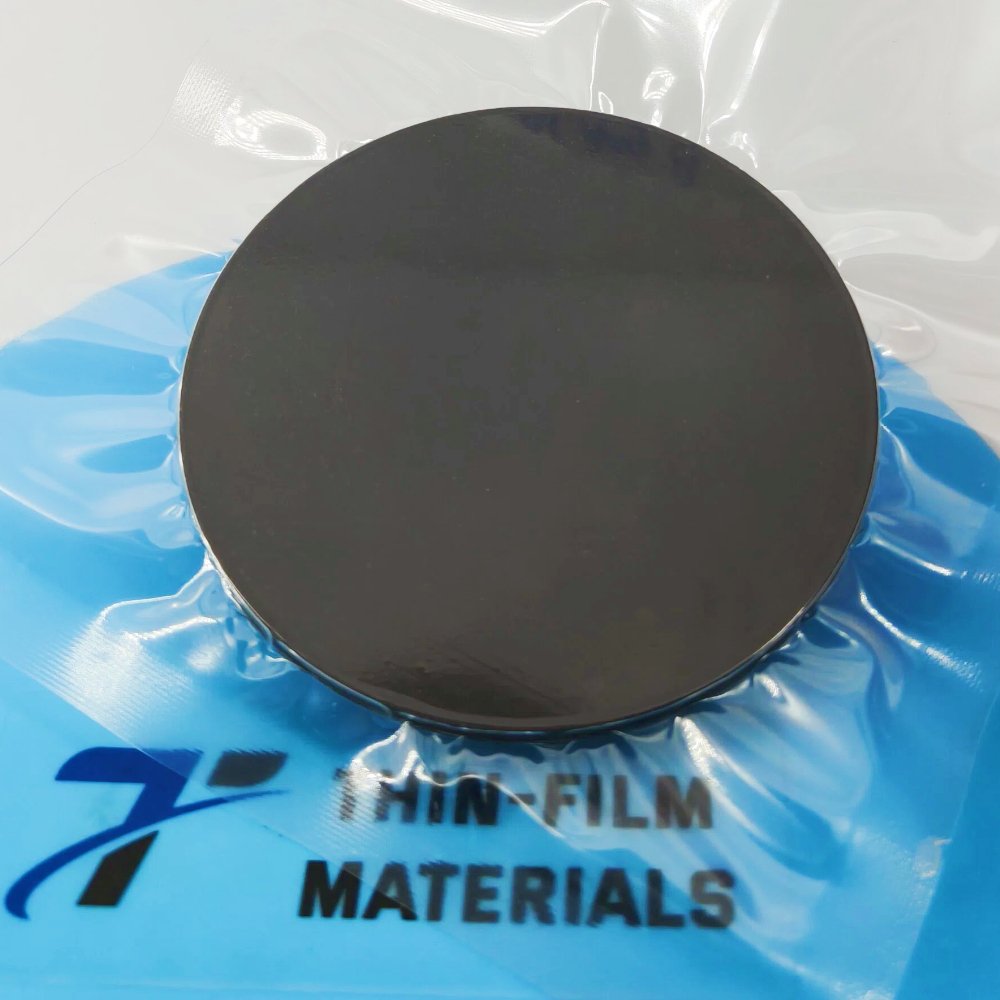

| What packaging is used? | Vacuum-sealed with protective foam, shipped in secure export cartons or wooden crates. |

| Which industries use AlMgB₁₄ films? | Automotive, aerospace, precision machinery, electronics, and academic research. |

| Do you support large-diameter targets? | Yes. Custom sizes up to 300 mm diameter can be manufactured. |

Packaging

Each Aluminum Magnesium Boride (AlMgB₁₄, 1:1:14) Sputtering Target is clearly labeled and vacuum-sealed to protect against moisture and environmental contamination. Reinforced cushioning and export-grade cartons ensure safe transport and handling.

Conclusion

The Aluminum Magnesium Boride (AlMgB₁₄) Sputtering Target offers a rare combination of superhardness, low friction, and thermal stability, making it ideal for protective and tribological thin films. We provide custom dimensions, bonded target options, and technical support tailored to diverse PVD system requirements.

For detailed specifications or a quotation, please contact us at sales@thinfilmmaterials.com.

Reviews

There are no reviews yet.