Lanthanum Trifluoride (LaF₃) is a technologically important rare-earth fluoride widely used as an evaporation material in vacuum thin-film deposition. Within the family of fluoride materials employed for optical and functional coatings, LaF₃ occupies a distinct niche due to its balanced optical properties, chemical stability, and reliable evaporation behavior. These characteristics make it a preferred choice for advanced optical systems, infrared components, laser devices, and research-oriented thin-film development.

This article provides a systematic overview of the intrinsic uniqueness of LaF₃ evaporation materials and a detailed analysis of their major application scenarios.

1. Material Characteristics That Define the Uniqueness of LaF₃

1.1 Broad Optical Transparency from UV to Infrared

One of the most notable features of LaF₃ is its wide optical transmission window. LaF₃ exhibits high transparency across the ultraviolet (UV), visible, and mid-infrared regions. Compared with many oxide materials, fluoride compounds such as LaF₃ show significantly lower phonon absorption in the infrared, making them highly suitable for IR optical systems.

This broad transparency allows LaF₃ films to function effectively in broadband optical designs where consistent performance across multiple wavelength bands is required.

1.2 Favorable Refractive Index for Multilayer Optical Design

in multilayer thin-film stacks, where precise refractive-index contrast is essential for tailoring reflection, transmission, and phase behavior.

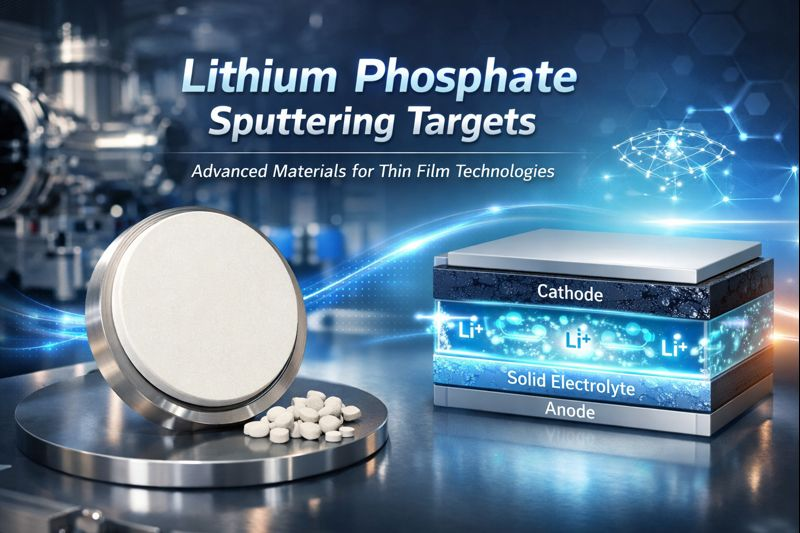

In optical coating engineering, LaF₃ is often paired with higher-index materials to construct:

Anti-reflection coatings

Dielectric mirrors

Optical band-pass and edge filters

Its stable refractive index contributes to predictable optical performance and repeatable coating design.

1.3 Improved Environmental and Chemical Stability

Compared with some traditional fluoride materials, LaF₃ demonstrates better resistance to moisture and environmental degradation. While fluorides are generally more sensitive to humidity than oxides, LaF₃ coatings show relatively enhanced durability when properly deposited under controlled vacuum conditions.

This stability is especially important for optical components exposed to fluctuating temperatures, moderate humidity, or long-term operational environments, where coating degradation can directly impact optical efficiency.

1.4 Stable Evaporation Behavior in Vacuum Deposition

From a processing perspective, LaF₃ exhibits controlled vapor pressure and stable evaporation characteristics during thermal evaporation or electron-beam evaporation. This allows for:

- Smooth deposition rates

- Uniform film thickness

- Reduced compositional deviation

Such behavior is critical in precision optical coatings, where thickness control at the nanometer scale determines final optical performance.

1.5 Compatibility with High-Purity Thin-Film Requirements

High-purity LaF₃ evaporation materials (commonly 3N–5N) are well suited for advanced optical and electronic applications. Low impurity levels minimize optical absorption, scattering losses, and defect formation within the deposited film. This makes LaF₃ particularly suitable for laser optics, infrared sensors, and scientific instrumentation.

2. Major Application Scenarios of LaF₃ Evaporation Materials

2.1 Optical Coatings for Precision Optics

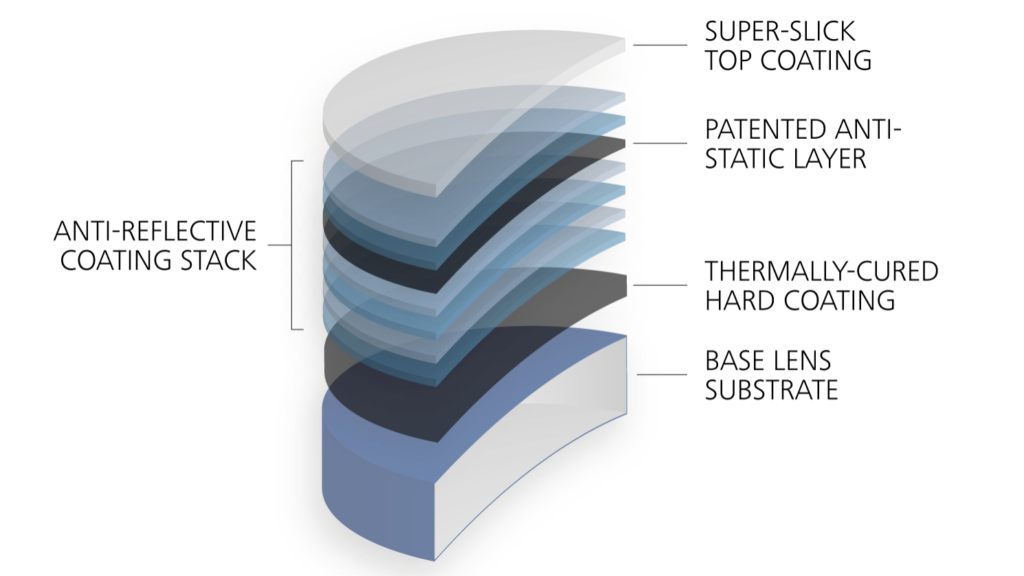

LaF₃ is extensively used in optical coating systems as a low-index fluoride layer. Typical applications include:

- Anti-reflection coatings on lenses and windows

- Multilayer dielectric coatings for optical filters

- Protective optical layers for scientific instruments

Its optical stability and wide transparency range make LaF₃ especially valuable in high-precision optical assemblies used in laboratories, aerospace optics, and industrial measurement systems.

2.2 Infrared Optical Components and Systems

Thanks to its excellent infrared transmission, LaF₃ is widely applied in coatings for infrared optics, such as:

- Infrared lenses and domes

- Thermal imaging windows

- Spectroscopic optical components

In these systems, LaF₃ coatings help minimize reflection losses and improve signal throughput, which is critical for accurate infrared detection and imaging.

2.3 Laser and Photonics Applications

In laser systems, LaF₃ thin films are used as functional optical layers or protective coatings. Their low absorption and good laser damage resistance contribute to:

- Enhanced laser efficiency

- Improved coating lifetime

- Reduced thermal loading

These properties are especially important in high-power or precision laser applications where optical losses and coating degradation must be strictly controlled.

2.4 Display and Optoelectronic Technologies

In certain display and optoelectronic applications, LaF₃ coatings are used to optimize light management and optical performance. Fluoride-based coatings are often preferred in systems requiring low absorption and high transparency, particularly in specialized or research-driven optoelectronic devices.

2.5 Research and Advanced Thin-Film Development

LaF₃ is frequently selected in research environments for:

- Thin-film material characterization

- Optical constant studies

- Development of fluoride-based multilayer structures

Its predictable deposition behavior and stable properties make LaF₃ a reliable material for experimental studies, pilot-scale coating development, and academic research.

3. Position of LaF₃ Among Fluoride Evaporation Materials

Within the broader family of fluoride evaporation materials such as MgF₂, CaF₂, and AlF₃, LaF₃ offers a distinctive balance of infrared transparency, environmental stability, and optical performance. While MgF₂ is widely used for visible-range anti-reflection coatings, LaF₃ extends performance further into the infrared, making it a strategic choice for broadband and IR-focused optical designs.

Conclusion

Lanthanum Trifluoride (LaF₃) evaporation materials are distinguished by their broad optical transparency, suitable refractive index, chemical stability, and reliable vacuum evaporation behavior. These attributes enable LaF₃ to play a critical role in optical coatings, infrared systems, laser optics, optoelectronics, and advanced thin-film research.

For engineers and researchers seeking consistent, high-quality fluoride thin films with dependable performance across UV–VIS–IR wavelengths, LaF₃ remains a well-established and technically sound material choice.

For detailed specifications, purity options, and customized evaporation forms, please contact sales@thinfilmmaterials.com.