Tungsten Crucibles

TFM Engineering is a leading supplier of Tungsten Crucibles, including E-Beam Crucibles, Standard Crucibles and Custom Crucibles. We offer competitive pricing and excellent lead times on Tungsten Crucibles, and we can supply custom materials per any specs/drawings you provide.

Tungsten E-Beam Crucibles

Material: Tungsten, W 99.95%

Shape: Arc, Square, Rectangle, Cylinder, Boat

Outer Diameter: ≤200mm / Height: ≤500mm

Deposition thickness: ≤10mm

Standard Capacities: 1mL ~ 40mL, Can be Customized

- Custom sizes available upon request.

- Recommended for chrome evaporation.

- Refractory metal crucibles can be good alternatives for other carbon based crucibles where there are concerns with trace carbon contamination.

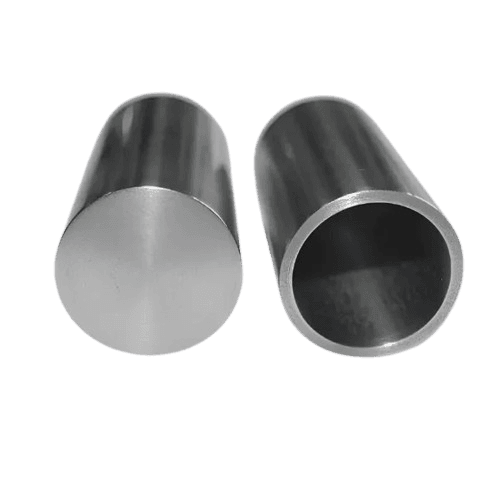

Tungsten Standard Crucible (Cylindrical)

Material: Tungsten, W≥99.95%

Density: ≥18.2g/cm3

Surface: Ra≤1.6

Operating temperature: ≤2,400 Degree C

Size: Customized Sizes

Production method: Sintered (OD>70mm); Forged (OD<70mm)

Other: With or Without Lid

Custom Tungsten Crucible

Material: Tungsten or Tungsten Alloy

Purity: 99% ~ 99.9999%

Outer Diameter: ≤200mm

Height: ≤500mm

Deposition thickness: ≤10mm

Other: Tailored Shape, Tailored Sizes

Tungsten Crucible Specifications

E-Beam Crucible

Cylindrical Crucible

Tungsten E-Beam Crucible

Cylindrical Tungsten Crucible Specifications

| Outer Diameter (mm) | Wall Thickness (mm) | Height (mm) |

|---|---|---|

| 10 ~ 30 | 1.0 ~ 3 | 20 ~ 50 |

| 30 ~ 50 | 2~ 10 | 20 ~ 100 |

| 50 ~ 100 | 3 ~ 15 | 30 ~ 150 |

| 100 ~ 150 | 3 ~ 15 | 30 ~ 500 |

| 150 ~ 200 | 5 ~ 20 | 30 ~ 500 |

| 200 ~ 300 | 8 ~ 20 | 30 ~ 500 |

| 300 ~ 400 | 8 ~ 30 | 40 ~ 500 |

| 400 ~ 450 | 8 ~ 30 | 50 ~ 500 |

| 450 ~ 620 | 8~ 30 | 50 ~ 500 |

| Shape and size can be tailored. Rectangular tungsten crucible is available. | ||

Description

Tungsten crucibles and other parts can be used for sapphire crystal growth and rare-earth melting due to their high-temperature resistance, low pollution, and other excellent characteristics. Tungsten’s melting point is 3422°C (6192°F), making it perfect as a crucible.

The tungsten crucibles manufactured through the chemical vapor deposition (CVD) process exhibit notable characteristics, including a high density reaching up to 98.5% of theoretical density, exceptional purity at 99.9999%, and a distinctive microstructure characterized by columnar or multilayer columnar crystals.

These tungsten crucibles find widespread applications in the production of monocrystals from molten corundum and play a vital role in electronics and thermal vaporization technologies for depositing various substances. Their high melting point is a key attribute of high-temperature furnaces.

Our tungsten crucibles are distinguished by their outstanding thickness transition, smooth surface, high purity, and robust resistance to creep, making them well-suited for demanding applications in high-temperature environments.

Applications of Tungsten Crucibles

Tungsten crucibles find versatile applications across various industries due to their unique properties. Here are some common applications of tungsten crucibles:

- Crystal Growth:Tungsten crucibles are widely used in the growth of single crystals from molten materials. Industries such as semiconductor manufacturing and research rely on tungsten crucibles to produce high-quality crystals.

- Thermal Vaporization: Tungsten crucibles play a crucial role in technologies involving the thermal vaporization and deposition of different substances. This is particularly relevant in processes such as physical vapor deposition (PVD) and chemical vapor deposition (CVD) for coating and thin-film deposition.

- High-Temperature Furnaces: Tungsten crucibles are integral components in high-temperature furnaces due to tungsten's exceptional melting point. They contribute to maintaining a stable and controlled environment for processes requiring elevated temperatures, such as sintering and heat treatment.

- Metal Casting: In some specialized metal casting applications, tungsten crucibles are employed to contain and handle molten metals. Tungsten's high melting point and resistance to thermal shock make it suitable for these demanding processes.

- Sintering and Heat Treatment:Tungsten crucibles are used in processes like sintering and heat treatment where high temperatures are required to achieve specific material properties. These applications are common in the production of ceramics, powders, and advanced materials.

- Electronics: Tungsten crucibles are utilized in various electronic manufacturing processes, including the production of semiconductors and other electronic components. Their ability to withstand high temperatures and resist contamination is crucial in these applications.

- Research and Development: Tungsten crucibles are often employed in research laboratories for experimental purposes, particularly in high-temperature environments. Their durability and resistance to chemical reactions make them valuable tools in scientific investigations.

- Sapphire Crystal Growth:Tungsten crucibles are specifically used in the growth of sapphire crystals, which have applications in industries such as optics, LED manufacturing, and electronics.

Packaging

Our Tungsten Crucibles are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.