Iridium Oxide Sputtering Target Description

The Iridium Oxide Sputtering Target from TFM contains iridium (Ir) and oxygen (O). Iridium oxide (IrO2) is a blue-black solid and is the only well-characterized oxide of iridium. The structure of IrO2 is similar to the rutile structure of TiO2, featuring six-coordinate iridium and three-coordinate oxygen. There are several methods for obtaining iridium oxide, which can be categorized into modification and reactive deposition techniques.

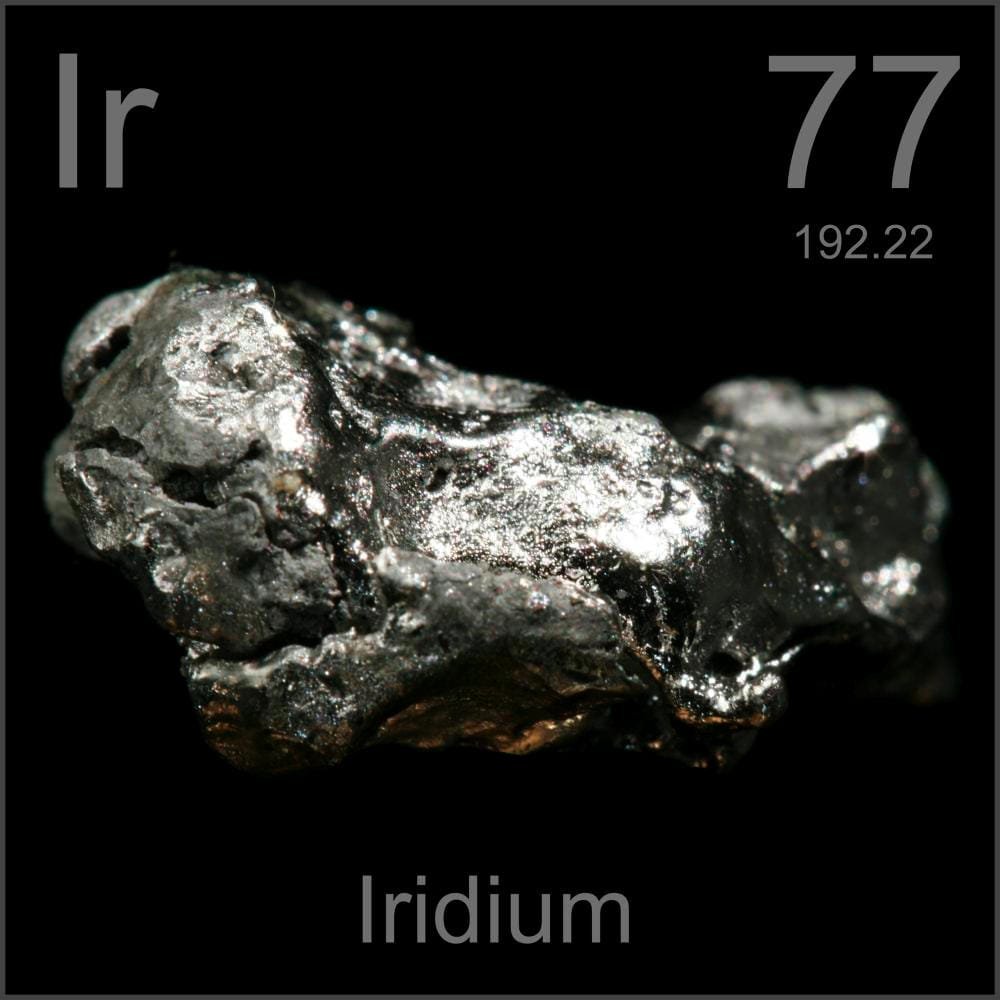

Related Product: Iridium Sputtering Target

Iridium is a rare, hard, lustrous, brittle, and very dense metal that resembles platinum. Chemically, it is almost as unreactive as gold and is known for being the most corrosion-resistant metal, resisting attack by any acid. Iridium is generally credited with being the second densest element after osmium based on measured density, although calculations involving the space lattices of the elements indicate that iridium is actually denser.

Iridium Oxide Sputtering Target Specification

| Material Type | Iridium Oxide |

| Symbol | IrO2 |

| Color/Appearance | Black Target |

| Melting Point | 1,100° C (2,012° F) |

| Boiling Point | N/A |

| Density | 11.7 g/cm3 |

| Type of Bond | Indium, Elastomer |

| Available Sizes | Dia.: 1.0″, 2.0″, 3.0″, 4.0″, 5.0″, 6.0″ Thick: 0.125″, 0.250″ |

Iridium Oxide Sputtering Target Applications

The Iridium Oxide (IrO2) Sputtering Target is used for thin film deposition in various applications, including fuel cells, decoration, semiconductors, displays, LEDs, photovoltaic devices, and glass coatings. IrO2 is also utilized in conjunction with other rare oxides, such as titanium nitride, in the coating of anode electrodes for industrial electrolysis and in microelectrodes for electrophysiology research.

Iridium Oxide Sputtering Target Bonding Services

Specialized bonding services for Iridium oxide Sputtering Targets, including indium and elastomeric bonding techniques, enhance performance and durability. Thin Film Materials (TFM) ensures high-quality solutions that meet industry standards and customer needs.

We also offer custom machining of backing plates, which is essential for sputtering target assembly. This comprehensive approach improves target design flexibility and performance in thin film deposition. Our channels provide detailed information about bonding materials, methods, and services, helping clients make informed decisions.

Packaging

IrO2 sputter coater target is carefully packaged in the plastic vacuum bag to prevent damage during storage and transportation and to preserve the quality of our products in their original condition. Also, the COA of the raw material would be packaged with the product.

Reviews

There are no reviews yet.