Gallium Oxide Sputtering Targets Description

The Gallium Oxide Sputtering Target is a high-purity, solid material used in the sputtering process for depositing thin films. Gallium oxide (Ga2O3) exists in five different polymorphic forms: monoclinic (β-Ga2O3), rhombohedral (α), defective spinel (γ), cubic (δ), and orthorhombic (ε). Of these, the β-polymorph is the stable form under standard conditions and is the most extensively studied and used in various applications.

Gallium is a chemical element named after France, derived from the Latin word *Gallia*. It was first identified in 1875 by the French chemist Paul-Émile Lecoq de Boisbaudran, who also successfully isolated it. Gallium is represented by the symbol “Ga” in the periodic table, with an atomic number of 31, located in Period 4 and Group 13, within the p-block. Its relative atomic mass is 69.723(1) Dalton, with the number in parentheses indicating the uncertainty in measurement.

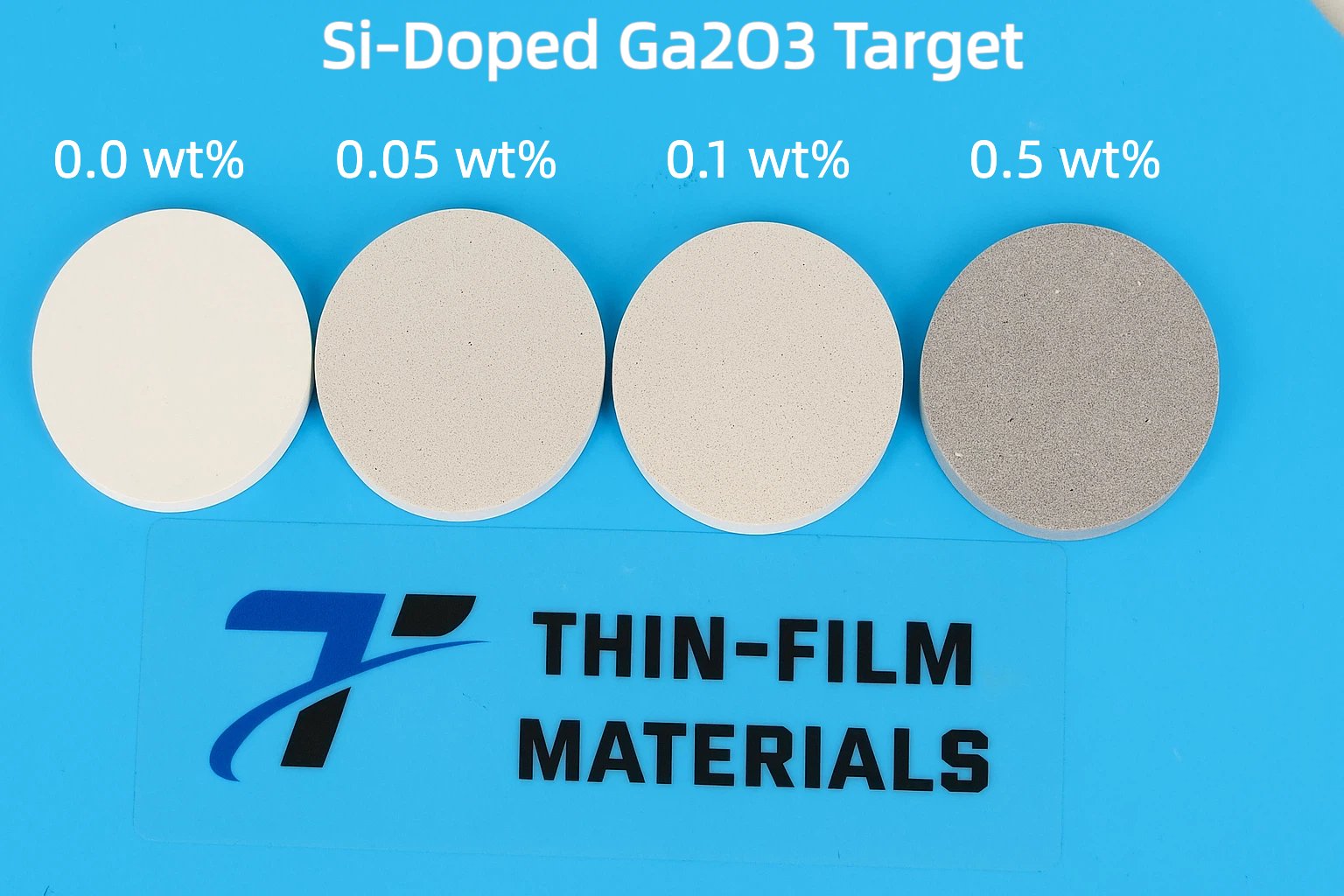

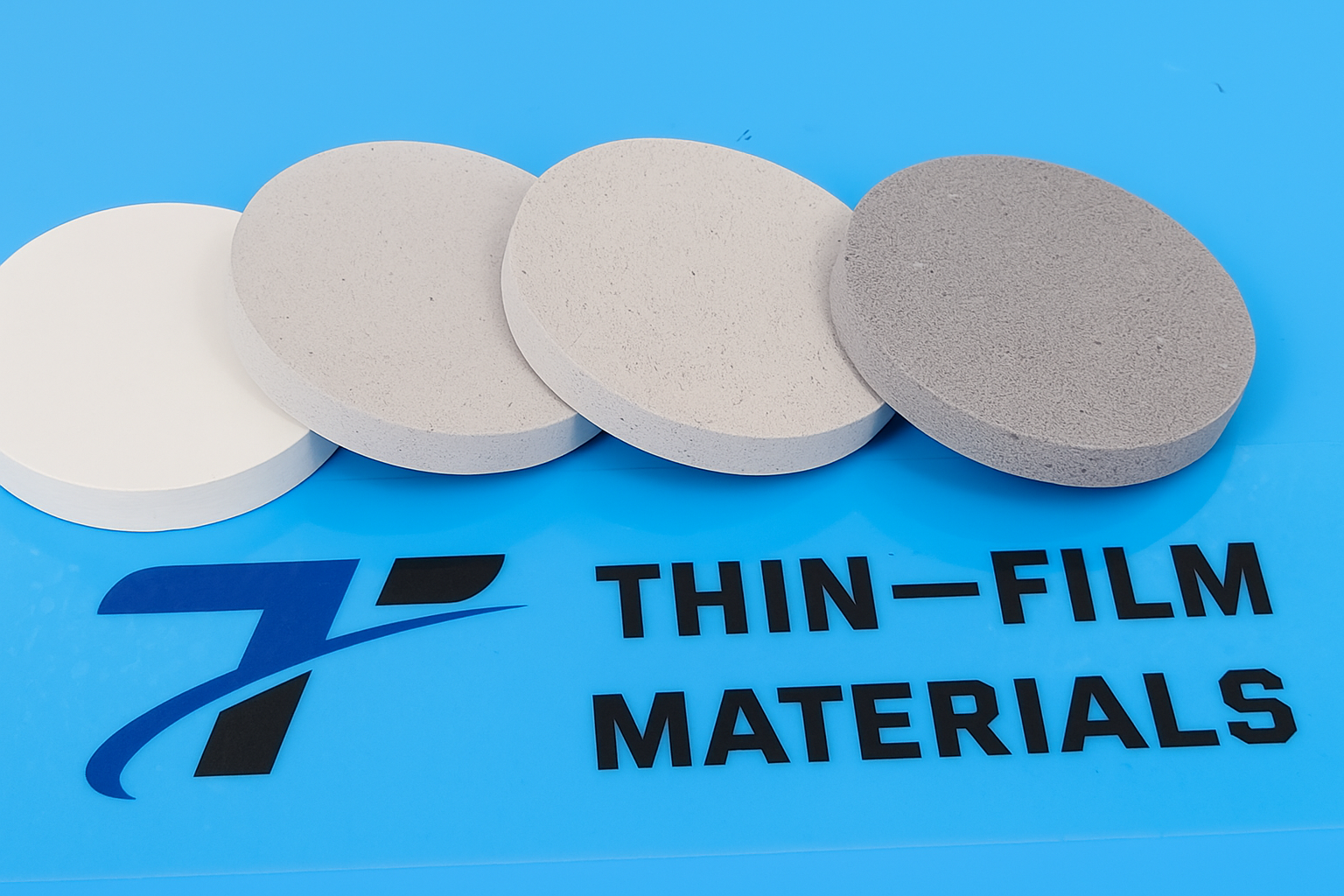

TFM can also provide Ga2O3 with silicon-doped, as well as other elements doped.

Related Product: Gallium Sputtering Target

Gallium Oxide Sputtering Targets Specifications

| Compound Formula | Ga2O3 |

| Molecular Weight | 187.44 |

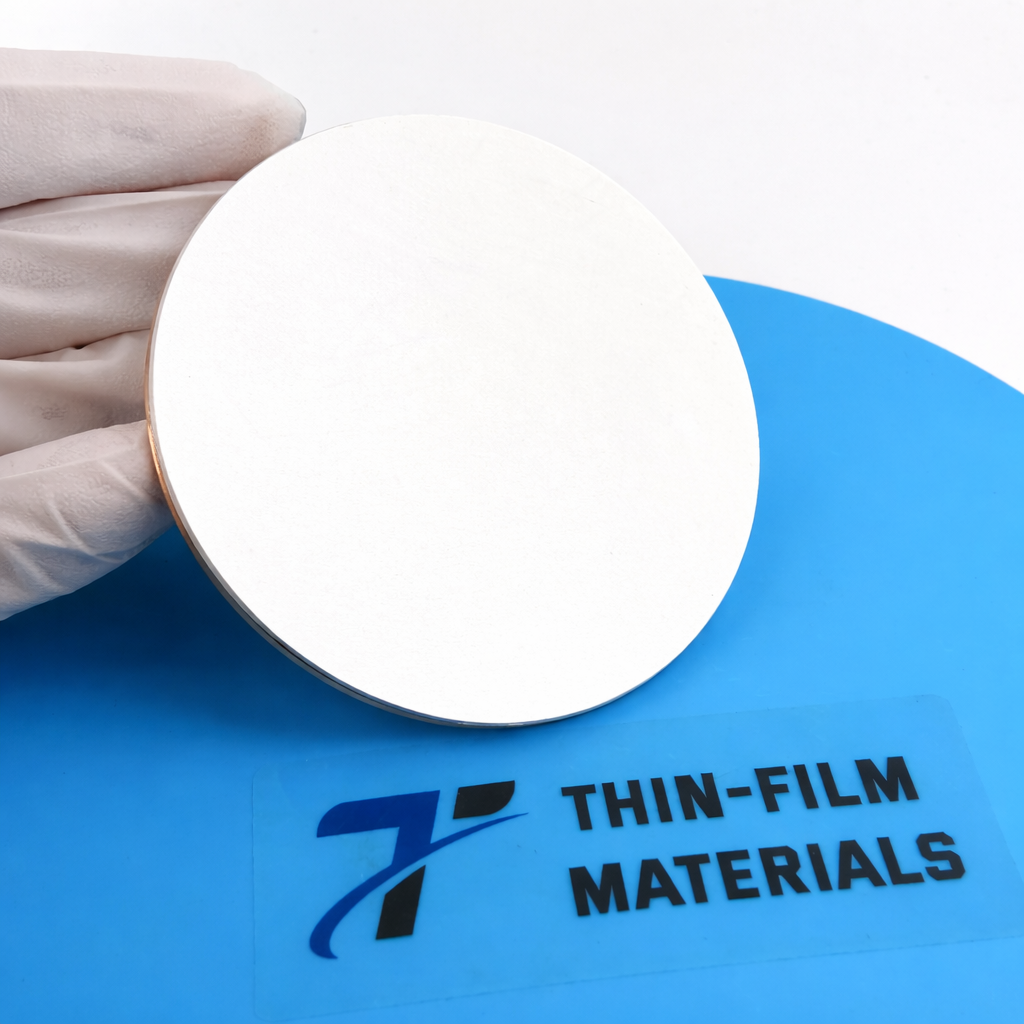

| Appearance | White Target |

| Melting Point | 1900℃ |

| Density | 5.88 g/cm3 |

| Available Sizes | Dia.: 1.0″, 2.0″, 3.0″, 4.0″, 5.0″, 6.0″ Thick: 0.125″, 0.250″ |

Gallium Oxide Sputtering Targets Handling Notes

Indium bonding is advisable for Gallium Oxide Sputtering Targets due to certain properties that make the material challenging to sputter, such as its brittleness and low thermal conductivity. These characteristics make the material prone to thermal shock, so indium bonding helps enhance the target’s performance and durability during the sputtering process.

Gallium Oxide Sputtering Targets Application

The Gallium Oxide Sputtering Target is utilized in the deposition of gallium oxide thin films for a range of applications, including optoelectronics, power electronics, solar cells, sensors, and catalysis. Its high purity ensures that the resulting thin films exhibit the desired properties and meet stringent quality standards.

Gallium Oxide Sputtering Targets Packaging

We take great care in handling our Gallium Oxide Sputtering Targets during storage and transportation to ensure they remain in pristine condition, preserving their quality and integrity.

Reviews

There are no reviews yet.