Introduction

Spherical Hastelloy X Powder (UNS N06002) is a nickel-based superalloy powder engineered for high-temperature strength, oxidation resistance, and structural stability. Originally developed for gas turbine and industrial furnace components, Hastelloy X offers excellent performance in environments exceeding 1000 °C. In spherical powder form, it is particularly suited for additive manufacturing (AM), metal injection molding (MIM), and powder metallurgy processes where flowability and uniform packing density are critical.

Detailed Description

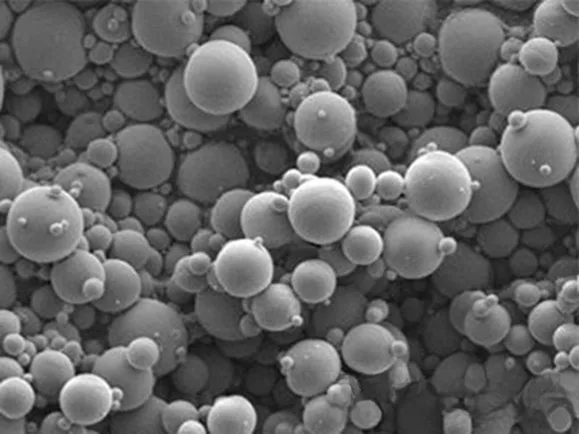

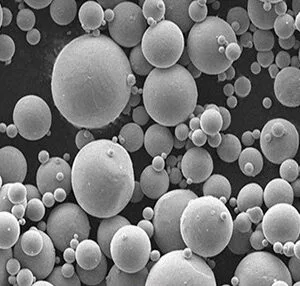

Our Spherical Hastelloy X Powder is produced using advanced gas atomization technology to achieve high sphericity, smooth particle surfaces, and a controlled particle size distribution. The alloy composition—primarily nickel with chromium, iron, molybdenum, and minor additions—provides strong solid-solution strengthening and superior oxidation resistance.

Strict control of oxygen and impurity content ensures mechanical reliability and minimizes inclusions that could compromise fatigue life. The spherical morphology promotes excellent powder flow, uniform layer deposition, and consistent energy absorption during laser or electron beam processing. The material demonstrates good weldability and crack resistance compared to many other high-strength superalloys, making it especially suitable for complex geometries and high-stress components.

Applications

Spherical Hastelloy X Powder is widely used in demanding thermal and corrosive environments, including:

Gas turbine combustor components

Heat exchangers and furnace hardware

Aerospace and power generation parts

Additive manufacturing (SLM, L-PBF, EBM)

Chemical processing equipment

High-temperature structural components

Technical Parameters

| Parameter | Typical Value / Range | Importance |

|---|---|---|

| Alloy Grade | UNS N06002 (Hastelloy X) | High-temperature superalloy |

| Morphology | Highly spherical | Improves flowability and packing |

| Particle Size | 15–45 µm / 45–105 µm / custom | Matches AM system requirements |

| Oxygen Content | ≤ 0.05–0.08% (typical) | Preserves ductility and fatigue life |

| Apparent Density | ~4.0–4.8 g/cm³ | Influences powder spreading |

| Flow Rate (Hall) | ≤ 25 s/50 g (typical) | Ensures stable processing |

Comparison with Related Superalloy Powders

| Material | Key Advantage | Typical Application |

|---|---|---|

| Hastelloy X (N06002) | Excellent oxidation resistance & weldability | Combustors & heat exchangers |

| Inconel 718 | High strength at moderate temperatures | Aerospace structural parts |

| Inconel 625 | Superior corrosion resistance | Marine & chemical processing |

| Haynes 230 | Enhanced creep strength | High-temperature components |

FAQ

| Question | Answer |

|---|---|

| Is this powder suitable for laser powder bed fusion (LPBF)? | Yes, it is optimized for SLM/L-PBF and EBM processes. |

| Can particle size distribution be customized? | Yes, tailored PSD ranges are available. |

| What is the main advantage of Hastelloy X? | Its combination of oxidation resistance, strength, and fabrication flexibility. |

| How is the powder packaged? | Vacuum-sealed or inert-gas packed in sealed containers to prevent oxidation. |

Packaging

Our Spherical Hastelloy X Powder (UNS N06002) is vacuum-sealed or packed under inert gas in moisture-resistant containers. Each batch is clearly labeled for full traceability and protected with export-grade packaging to ensure safe storage and transportation.

Conclusion

Spherical Hastelloy X Powder (UNS N06002) provides a high-performance solution for additive manufacturing and powder metallurgy applications in extreme thermal environments. With controlled chemistry, excellent sphericity, and customizable particle sizes, it delivers reliable mechanical strength and oxidation resistance for aerospace, energy, and industrial sectors.

For detailed specifications and a quotation, please contact us at sales@thinfilmmaterials.com

Reviews

There are no reviews yet.