Description

2219 Aluminum Alloy is a robust material renowned for its exceptional strength and mechanical characteristics. This alloy, which contains copper, is known for its impressive toughness and high resistance to stress corrosion during fabrication. These attributes make it an ideal choice for applications in supersonic aircraft components and high-temperature structural uses.

This powder is compatible with a range of metal 3D printers, including those from manufacturers such as Renishaw, EOS, ConceptLaser, SLM, 3D Systems, Arcam, and others.

Specifications

Particle size | 0-20μm, 15-45μm, 15-53μm, 53-105μm, 53-150μm, 105-250μm |

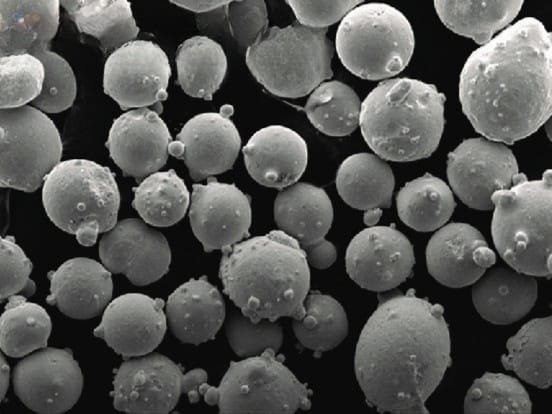

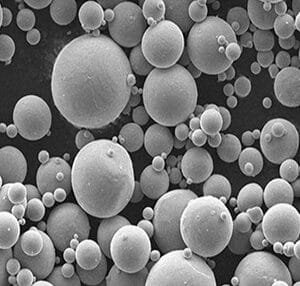

Degree of sphericity | Spherical or nearly spherical, microscopic particle sphericity Ψ0≥0.85 |

Appearance | Visually silvery gray, no obvious oxidized particles |

Application in 3D printing | SLM selection laser melting, EBM electron beam melting, LMD laser metal deposition, etc. |

Other applications | Powder metallurgy (PM), injection molding (MIM), hot isostatic pressing (HIP), spray coating (SP), welding repair, etc. |

Applications

3D Printing

- SLM (Selective Laser Melting)

- EBM (Electron Beam Melting)

- LMD (Laser Metal Deposition)

Other Uses

- Powder Metallurgy (PM)

- Injection Molding (MIM)

- Hot Isostatic Pressing (HIP)

- Spray Coating (SP)

- Welding Repair

Specific Uses

- 3D Printing Material

- Low-Temperature Oxidant and Fuel for Spacecraft Launch Vehicles

- Structural Frameworks for Spacecraft and Supersonic Aircraft

Packaging

Spherical 2219 aluminum alloy powders are typically packaged as follows:

- 500 g per Bag

- 20 kg per Metal Can

- 100 kg and Above per Steel Drum (or customized options)

All packaging is designed to be suitable for air, sea, and road transportation.

Reviews

There are no reviews yet.