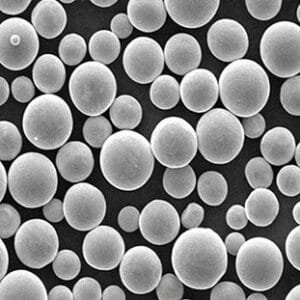

L605 Alloy Powder Description

L605 Alloy Powder Specifications

| Product Name | L605 Alloy (UNS R30605) Powder |

| Alloy Grade | GH605, L605 |

| Related Grades | / |

| Composition | Cr 19.0-21.0 Ni 9.0-11.0 Co Bal W 14.0-16.0 C 0.05-0.15 Fe 17-20Mn 1 max Si 1 max P 0.04 max S 0.03 max Cu 0.5 max1 |

| Size Grades | -105+45micron -53+15micron |

| ASTM | / |

| AMS Specification | 5537 |

Reviews

There are no reviews yet.