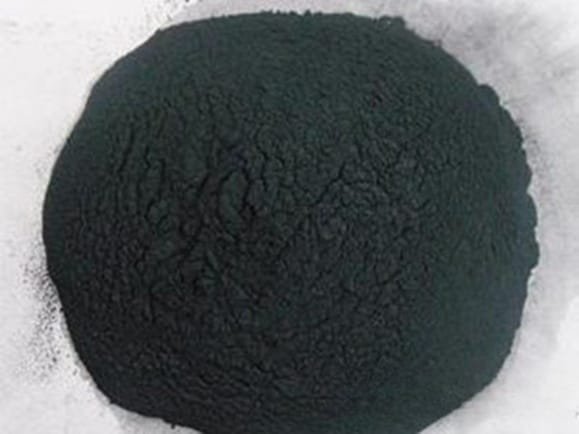

Overview of Spherical Yttrium Powder

Yttrium, a transition metal with characteristics similar to lanthanides, is commonly used in various advanced applications. The spherical form of yttrium powder is highly reactive when exposed to air and moisture, requiring careful handling. For optimal safety and preservation of its properties, TFM recommends processing spherical yttrium powder in an inert gas environment, such as argon.

Key Features of Spherical Yttrium Powder

Typical Chemical Composition (COA)

| Yttrium (Y) | 99.9% (REM) |

| Impurities (%): | |

| Ni | 0.0019 |

| Cu | 0.0003 |

| Fe | 0.0039 |

| Pb | 0.0002 |

| Zn | 0.0003 |

| Mg | 0.0012 |

| Mn | 0.0006 |

| Si | 0.0008 |

| Al | 0.0007 |

| C | 0.0087 |

| S | 0.0023 |

| Ca | 0.001 |

| Na | 0.0019 |

| O | 0.29 |

Applications of Spherical Yttrium Powder

One of the primary uses of spherical yttrium powder is in laser cladding, a process that enhances the surface properties of metals by fusing materials through laser heat. This makes it suitable for industries requiring high-performance coatings.

Packaging and Handling of Spherical Yttrium Powder

TFM ensures that each batch of spherical yttrium powder is carefully labeled and tagged for easy identification and strict quality control. The packaging is designed to protect the powder during transport and storage, minimizing the risk of damage or contamination during shipment.

Reviews

There are no reviews yet.