Tantalum Powder

High-capacitance Tantalum Powder

Features of Our Tantalum Powder

Our tantalum powder is produced using the sodium reduction method, ensuring high purity and quality. It is ideal for manufacturing capacitors with a rated withstand voltage ranging from 4V to 40V. This powder is especially well-suited for making chips, impregnated tantalum electrolytic capacitors, and organic polymer capacitors. It offers excellent moldability, high specific capacitance, minimal leakage current, and low equivalent series resistance, making it a top choice for advanced capacitor technologies.

Electrical Properties

| Grade | Capacitance(+10%-6%) (μFV/g) | Volume shrinkage (%) | Current leakage (nA/μFV) | Dissipation factor (%) | Breakdown voltage (V) |

|---|---|---|---|---|---|

| FTa16-700 | 70000 | ≤15 | ≤0.5 | ≤40 | ≥120 |

| FTa16-500 | 50000 | ≤18 | ≤0.4 | ≤25 | ≥120 |

| FTa16-400 | 40000 | ≤18 | ≤0.4 | ≤20 | ≥120 |

| FTa16-300 | 30000 | ≤18 | ≤0.4 | ≤20 | ≥120 |

| FTa16-230 | 23000 | ≤18 | ≤0.4 | ≤15 | ≥140 |

Chemical Analysis of Tantalum Powder(Maximum Values/wt ppm)

| Grade | O | C | N | H | Fe | Ni | Cr | Si | Ti | Nb | Na+K | W | Mo |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FTa16-700 | 4000 | 40 | 1000 | 180 | 30 | 30 | 20 | 20 | 5 | 30 | 40 | 10 | 5 |

| FTa16-500 | 3500 | 40 | 500 | 170 | 30 | 30 | 20 | 20 | 5 | 30 | 30 | 10 | 5 |

| FTa16-400 | 3000 | 40 | 500 | 170 | 30 | 30 | 20 | 20 | 5 | 30 | 30 | 10 | 5 |

| FTa16-300 | 2500 | 30 | 400 | 120 | 30 | 30 | 20 | 20 | 5 | 30 | 30 | 10 | 5 |

| FTa16-230 | 2500 | 30 | 150 | 120 | 30 | 30 | 20 | 20 | 5 | 30 | 20 | 10 | 5 |

Physical Properties

| Grade | Bulk density(g/cm3) | Average fisher size(um) | Particle-size distribution (-325mesh%) |

|---|---|---|---|

| FTa16-700 | 1.5-2.1 | 1.8-3.0 | ≤35 |

| FTa16-500 | 1.6-2.2 | 2.0-3.4 | ≤35 |

| FTa16-400 | 1.6-2.2 | 2.0-3.5 | ≤35 |

| FTa16-300 | 1.7-2.3 | 2.4-3.5 | ≤35 |

| FTa16-230 | 1.7-2.3 | 2.4-3.5 | ≤35 |

Middle-Voltage Tantalum Powder

Features:

Electrical Properties

| Grade | Capacitance(+10%-6%) (u FV/g) | Current leakage (nA/u FV) | Dissipation factor (%) | Breakdown voltage (V) |

|---|---|---|---|---|

| FDP-100 | 10000 | ≤0.4 | ≤10 | ≥180 |

| FDP -80 | 8000 | ≤0.4 | ≤10 | ≥230 |

| FDB -52 | 5200 | ≤0.5 | ≤8 | ≥240 |

| FTa40-42 | 4200 | ≤0.5 | ≤8 | ≥240 |

Chemical Analysis (Maximum Values/wt ppm)

| Grade | O | C | N | Fe | Ni | Cr | Si | Ti | Nb | Na | K | W | Mo | Al | Mn |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FDP-100 | 2200 | 60 | 100 | 50 | 10 | 15 | 20 | 5 | 30 | 15 | 15 | 20 | 10 | 5 | 5 |

| FDP-80 | 2100 | 60 | 100 | 50 | 10 | 15 | 20 | 5 | 30 | 10 | 10 | 20 | 10 | 5 | 5 |

| FDB-52 | 1700 | 45 | 50 | 35 | 10 | 15 | 20 | 5 | 30 | 10 | 10 | 20 | 10 | 5 | 5 |

| FTa40-42 | 1700 | 45 | 50 | 35 | 10 | 15 | 20 | 5 | 30 | 10 | 10 | 20 | 10 | 5 | 5 |

Physical Properties

| Grade | Bulk density (g/cm3) | Average fisher size (um) | Particle-size distribution (-325mesh%) |

|---|---|---|---|

| FDP-100 | 1.5-2.3 | 3.0-5.0 | ≤30 |

| FDP-80 | 1.7-2.5 | 3.0-5.0 | ≤30 |

| FDB-52 | 3.0-4.0 | 4.5-8.0 | ≤30 |

| FTa40-42 | 3.5-4.5 | 5.0-9.0 | ≤30 |

High-Voltage Tantalum Powder

Features:

• Simple structure.

• Smaller specific surface area

• Good voltage resistance, and high breakdown voltage

• It’s suitable for making medium to high voltage solid tantalum electrolytic capacitors with specifications greater than 63V

Electrical Properties

| Grade | Capacitance (+10%-6%)(uFV/g) | Current leakage (nA/u FV) | Dissipation factor (%) | Breakdown voltage (V) |

|---|---|---|---|---|

| FTa50-50 | 5000 | ≤0.6 | ≤6 | ≥260 |

| FTa50-40 | 4000 | ≤0.6 | ≤6 | ≥260 |

| FDC-50 | 5000 | ≤0.7 | ≤6 | ≥300 |

| FTa63-40 | 4000 | ≤0.7 | ≤6 | ≥300 |

| FTa63-35 | 3500 | ≤0.7 | ≤6 | ≥300 |

| FTa63-28 | 2800 | ≤0.7 | ≤5 | ≥300 |

| FTa63-25 | 2500 | ≤0.7 | ≤4 | ≥300 |

| FTa63-20 | 2000 | ≤0.7 | ≤3 | ≥300 |

| FTa63-15 | 1500 | ≤0.7 | ≤3 | ≥300 |

| FTa63-10 | 1000 | ≤0.7 | ≤3 | ≥300 |

Chemical Analysis (Maximum Values/wt ppm)

| Grade | O | N | C | Fe | Ni | Cr | Si | Ti | Nb | W | Mo | AL | Mn |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FTa50-50 | 1800 | 60 | 50 | 40 | 15 | 15 | 20 | 10 | 30 | 10 | 10 | 5 | 5 |

| FTa50-40 | 1600 | 60 | 50 | 40 | 15 | 15 | 20 | 10 | 30 | 10 | 10 | 5 | 5 |

| FDC-50 | 2000 | 60 | 60 | 50 | 15 | 15 | 20 | 10 | 30 | 10 | 10 | 5 | 5 |

| FTa63-40 | 1800 | 60 | 40 | 35 | 15 | 15 | 20 | 10 | 30 | 10 | 10 | 5 | 5 |

| FTa63-35 | 1600 | 60 | 40 | 30 | 15 | 15 | 20 | 10 | 30 | 10 | 10 | 5 | 5 |

| FTa63-28 | 1400 | 40 | 30 | 20 | 10 | 10 | 20 | 10 | 30 | 10 | 10 | 5 | 5 |

| FTa63-25 | 1400 | 40 | 30 | 20 | 10 | 10 | 20 | 10 | 30 | 10 | 10 | 5 | 5 |

| FTa63-20 | 1200 | 40 | 25 | 15 | 10 | 10 | 20 | 5 | 30 | 10 | 10 | 5 | 5 |

| FTa63-15 | 1000 | 40 | 25 | 15 | 10 | 10 | 20 | 5 | 30 | 10 | 10 | 5 | 5 |

| FTa63-10 | 1000 | 40 | 25 | 15 | 10 | 10 | 20 | 5 | 30 | 10 | 10 | 5 | 5 |

Physical Properties

| Grade | Bulk density(g/cm3) | Average fisher size(μm) |

|---|---|---|

| FTa50-50 | 2.5-3.5 | 5.5-7.5 |

| FTa50-40 | 3.0-4.0 | 7.5-11.0 |

| FDC-50 | 2.5-3.5 | 4.0-7.0 |

| FTa63-40 | 3.5-4.5 | 8.0-11.0 |

| FTa63-35 | 3.5-4.5 | 8.0-12.0 |

| FTa63-28 | 3.5-5.5 | 8.0-12.0 |

| FTa63-25 | 4.0-6.0 | 9.0-14.0 |

| FTa63-20 | 4.0-6.0 | 8.0-13.0 |

| FTa63-15 | 5.0-6.5 | 9.0-15.0 |

| FTa63-10 | 5.5-6.5 | 10.0-20.0 |

Tantalum powder for metallurgical purposes

Features:

• Appearance: Dark grey powder or black powder.

• Application: Used for making various tantalum processing materials and alloy additives

Grade:FTa-01, FTa-02, FTa-1

| Grade | FTa-01 | FTa-02 | FTa-1 | |

|---|---|---|---|---|

| Main content | Ta,%,Minimum | 99.95 | 99.95 | 99.95 |

| Impurity content , %,max | O | 0.100 | 0.120 | 0.180 |

| C | 0.005 | 0.005 | 0.008 | |

| N | 0.005 | 0.005 | 0.008 | |

| H | 0.003 | 0.003 | 0.003 | |

| Fe | 0.004 | 0.004 | 0.005 | |

| Ni | 0.003 | 0.003 | 0.005 | |

| Cr | 0.003 | 0.003 | 0.005 | |

| Nb | 0.003 | 0.003 | 0.005 | |

| W | 0.002 | 0.002 | 0.002 | |

| Mo | 0.001 | 0.001 | 0.002 | |

| Si | 0.003 | 0.003 | 0.005 | |

| Mn | 0.001 | 0.001 | 0.001 | |

| Ti | 0.001 | 0.001 | 0.001 | |

| Fsss(um) | 3.0-10.0 | 3.0-10.0 | 3.0-10.0 | |

| Sieve mesh | -80 | -80 | -80 | |

| Application | Tantalum processing and alloying additives | |||

| Special requirements to be agreed upon by the supplier and buyer | ||||

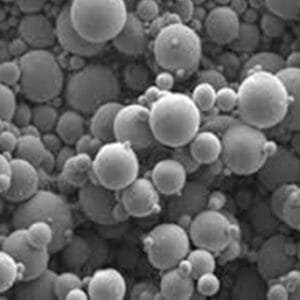

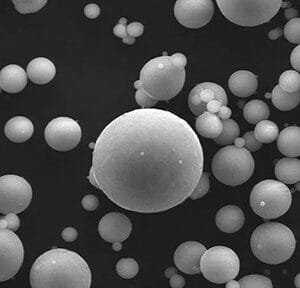

Spherical Tantalum Powder

Physical Properties

| Size | 15-53 um | ||||

| Apparet density | 9.75 g/cm3 | ||||

| Tap density | 10.8 g/cm3 | ||||

| Hall flow rate | 5.8 s/50g |

Chemical Composition

| Chemical Composition – by ICP-AES | ||||||||

| Element | Ta | Fe | Mg | Cu | Al | Ca | Sn | Mn |

| Value (%) | ≥99.9 | 0.002 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 |

| Element | Ti | Mo | W | Nb | Si | Cr | Ni | |

| Value (%) | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | |

| Gas Impurities | ||||||||

| Element | C | H | O | N | ||||

| Value (%) | 0.002 | 0.0018 | 0.045 | 0.004 | ||||

Tantalum Powder Features

– High resistance to corrosion;

– Resistant to high temperature.

Tantalum Powder Application

– Additive manufacturing (AM);

– Thermal spray (TSA);

Packing of Tantalum Powder:

Related Powders of Tantalum Powder

| Tantalum Powder | Niobium Powder | Hafnium Powder | Zirconium Powder |

Cobalt Powder | Chromium Powder | Titanium Powder | Tungsten Powder |

Molybdenum Powder | Nickel Powder | Copper Powder | Iron Powder |

Aluminium Powder | Silver Powder | Rhenium Powder | More Powder |

Reviews

There are no reviews yet.