Rhenium Powder

Introduction

Rhenium Powder is a rare, high-performance material valued for its exceptional melting point, unique catalytic properties, and outstanding resistance to wear and creep. With a melting temperature of 3,180 °C, it is one of the highest of all elements, making it indispensable for aerospace, electronics, and advanced chemical processes.

Detailed Description

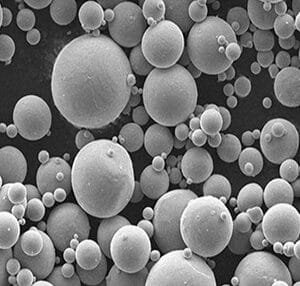

Rhenium Powder is produced through hydrogen reduction of ammonium perrhenate or other high-purity rhenium compounds. The resulting fine metallic powder typically exhibits high density, uniform particle size distribution, and excellent purity levels (from 99.9% to 99.999%).

Key characteristics include:

Ultra-high melting point: Ensures thermal stability in extreme environments.

High density (21.02 g/cm³): Provides strength for superalloys used in turbine blades and rocket engines.

Excellent catalytic activity: Promotes hydrogenation, reforming, and dehydrogenation reactions.

Good ductility: Unlike many refractory metals, rhenium can be processed into wires, foils, and compacts.

The powder form is especially suitable for powder metallurgy, additive manufacturing, and alloying applications, as it allows precise control over material composition and microstructure.

Applications

Rhenium Powder finds applications across advanced industries:

Aerospace & Defense: Strengthening nickel-based superalloys for jet engines and rocket propulsion systems.

Electronics: Used in filaments, electrical contacts, and thermocouples.

Catalysis: Platinum-rhenium catalysts in petrochemical refining (reforming of naphtha into high-octane gasoline).

Medical & Research: Targets for X-ray production, nuclear medicine, and high-temperature materials R&D.

Additive Manufacturing: 3D printing of high-temperature components for aerospace and energy industries.

Technical Parameters

| Parameter | Typical Value / Range | Importance |

|---|---|---|

| Purity | 99.9% – 99.999% | Determines reliability in aerospace & electronics |

| Particle Size | 1 – 50 µm (customizable) | Affects sintering, densification, and 3D printing |

| Density (theoretical) | 21.02 g/cm³ | Higher density improves mechanical strength |

| Melting Point | 3,180 °C | Enables use in ultra-high-temperature environments |

| Production Method | Hydrogen reduction | Ensures high purity and controlled particle morphology |

Comparison with Related Materials

| Material | Key Advantage | Typical Application |

|---|---|---|

| Rhenium | Ultra-high melting point & catalytic activity | Jet engines, reforming catalysts |

| Tungsten | Extremely high hardness | Electrical contacts, furnace parts |

| Molybdenum | Good balance of cost & performance | Electronics, structural alloys |

FAQ

| Question | Answer |

|---|---|

| Can the particle size be tailored? | Yes, particle size distribution can be customized for sintering, coating, or additive manufacturing needs. |

| How is it packaged? | Sealed in inert gas or vacuum-sealed bottles, inside protective cartons or wooden crates. |

| What is the delivery time? | Usually 2–4 weeks depending on order size and customization. |

| Which industries use it most? | Aerospace, electronics, petrochemicals, medical, and research institutions. |

| Is Rhenium Powder recyclable? | Yes, rhenium can be recovered and recycled from superalloys and catalysts. |

Packaging

Our Rhenium Powder is vacuum-sealed or argon-protected to prevent oxidation. Each container is clearly labeled with batch number, purity, and particle size information to ensure traceability and quality assurance during storage and transport.

Conclusion

Rhenium Powder is an indispensable material for extreme applications where thermal stability, high density, and catalytic activity are critical. Its unique combination of properties ensures reliability in aerospace propulsion, electronics, and refining processes.

For detailed specifications and a quotation, please contact us at sales@thinfilmmaterials.com.

Reviews

There are no reviews yet.