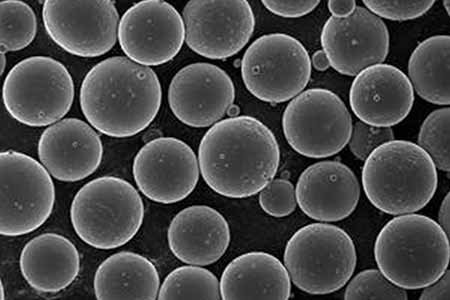

TFM offers a variety of metal powders, including chromium powder, manganese powder, stannum (tin) powder, molybdenum powder, and zinc powder, available in different particle sizes. Chromium and tin powders are commonly used in diamond carcass materials, while manganese powder is frequently utilized as an alloying element additive and in the production of diamond saw blades.

Molybdenum powder is primarily a raw material for producing molybdenum and its alloys. It is also used in manufacturing electric heating elements, molybdenum heads, and powder metallurgy materials due to its versatility in high-temperature applications.

Zinc metal powder is categorized based on particle size into fine, normal, and superfine varieties. As an essential industrial raw material, zinc powder has widespread applications in the chemical, metallurgical, pharmaceutical, and coatings industries. In particular, it plays a crucial role in the coatings sector, where it is widely used for both protective and aesthetic purposes.

In cold-galvanizing, zinc-rich coatings contain 40% to 70% zinc by weight. These coatings provide corrosion resistance for metal surfaces in various environments, including seawater, freshwater, and atmospheric exposure. Common applications include protecting ships, containers, chemical equipment, and other metal components from corrosion. Zinc coatings are also widely used in the treatment of automotive parts, motorcycles, bicycles, oil pipelines, steel structures in water management projects, and highway guardrails.

Metal Powder

| Grade | Product Name | Chemical Composition (wt%) | Particle Size | Apparent Density (g/cm3) |

|---|---|---|---|---|

| O-1 | Chromium (Cr) powder | Cr: >99.0 Other: <1.0 | -200 mesh customized sizes avaliable | – |

| O-2 | Sliver powder | Al:≥ 99.0% | 0-800nm customized sizes avaliable | – |

| O-3 | CuAg alloy powder | Ag: Bal Cu: 18 | – | – |

| O-4 | Manganese (Mn) powder | Mn: >99.9 Other: <0.1 | – | – |

| O-5 | Stannum (Sn)powder | Sn: 99.9 Fe: ≤0.015 Pb: <0.04 S: <0.01 Cu: <0.04 | -200 mesh | 3.3-4.3 |

| O-6 | Stannum (Sn)powder | Sn: 99.9 Fe: ≤0.015 Pb: <0.03 S: <0.01 Cu: <0.03 | -325mesh | 3.2-3.8 |

| O-7 | Stannum (Sn)powder | Sn: 99.9 Fe: ≤0.015 Pb: <0.04 S: <0.01 Cu: <0.03 | -100 mesh | 3.6-4.6 |

| O-8 | Molybedenum (Mo) powder | Mo: > 99.5 Other: ≤0.5 | -200 mesh customized sizes avaliable | – |

| O-9 | Tantalum (Ta) powder | Ta:≥ 99.9 Cu: ≤0.01 Ti: <0.03 Fe: <0.06 | 30-300 nm customized sizes avaliable | – |

| O-10 | Spuerfines Zinc (Zn) powder | Total Zn: ≥99 Zn metal: ≥97 Pb: <0.1 Cd: <0.05 Fe: <0.02 Acid-insoluble: <0.1 | -1500 mesh Max: ≤10 um -1200 mesh Max: ≤12 um -1000 mesh Max: ≤13 um -800 mesh Max: ≤15 um | – |

| O-11 | Normal Zinc (Zn) powder | Total Zn: ≥99 Zn metal: ≥97 Pb: <0.1 Cd: <0.05 Fe: <0.02 Acid-insoluble: <0.1 | -625 mesh Max: ≤20 um -500 mesh Max: ≤25 um -400 mesh Max: ≤38 um -325 mesh Max: ≤45 um | – |

| O-12 | Fines Zinc (Zn) powder | Total Zn: ≥99 Zn metal: ≥97 Pb: <0.1 Cd: <0.05 Fe: <0.02 Acid-insoluble: <0.1 | -200 mesh Max: ≤75 um -120 mesh Max: ≤120 um -60 mesh Max: ≤250 um -40 mesh Max: ≤425 um | – |

Oxide Ceramics powder

| Grade | Product Name | Chemical Composition (wt%) | Particle Size | Hardness | Temperature |

|---|---|---|---|---|---|

| O-13 | Yttrium oxide powder | Y2O3:≥ 99.99 | -200+325 mesh | – | – |

| O-14 | 7-8 Y2O3 zirconium powder | ZrO2+Y2O3 >98 | -200+325 mesh | HV0.3 600 | ≤ 1700℃ |

| O-15 | Chromium oxide powder | Cr2O3:≥ 98 | -200+325 mesh | HV0.3 900-1200 | ≤ 540℃ |

| O-16 | Composition powder | Cr+Al: 20 Ni+Co: 75 | -140+325 mesh | HRC 20 | ≤ 900℃ |

Reviews

There are no reviews yet.