Introduction: A Crucial Choice in High-Temperature Materials Science

In the world of advanced materials processing, particularly in metallurgy, ceramics, and semiconductor fabrication, the choice of crucible material can significantly influence the outcome of high-temperature experiments. Among the myriad options available, alumina crucibles and zirconia crucibles stand out as the most widely used and debated. Both materials boast exceptional thermal and chemical properties, but depending on the application, one may outperform the other.

This article offers a deep dive into the comparative advantages and limitations of alumina (Al₂O₃) crucibles versus zirconia (ZrO₂) crucibles, analyzing their performance in terms of high-temperature stability, chemical inertness, mechanical durability, and cost-effectiveness. By understanding these differences, laboratory professionals, researchers, and engineers can make informed decisions when selecting the most appropriate crucible for their processes.

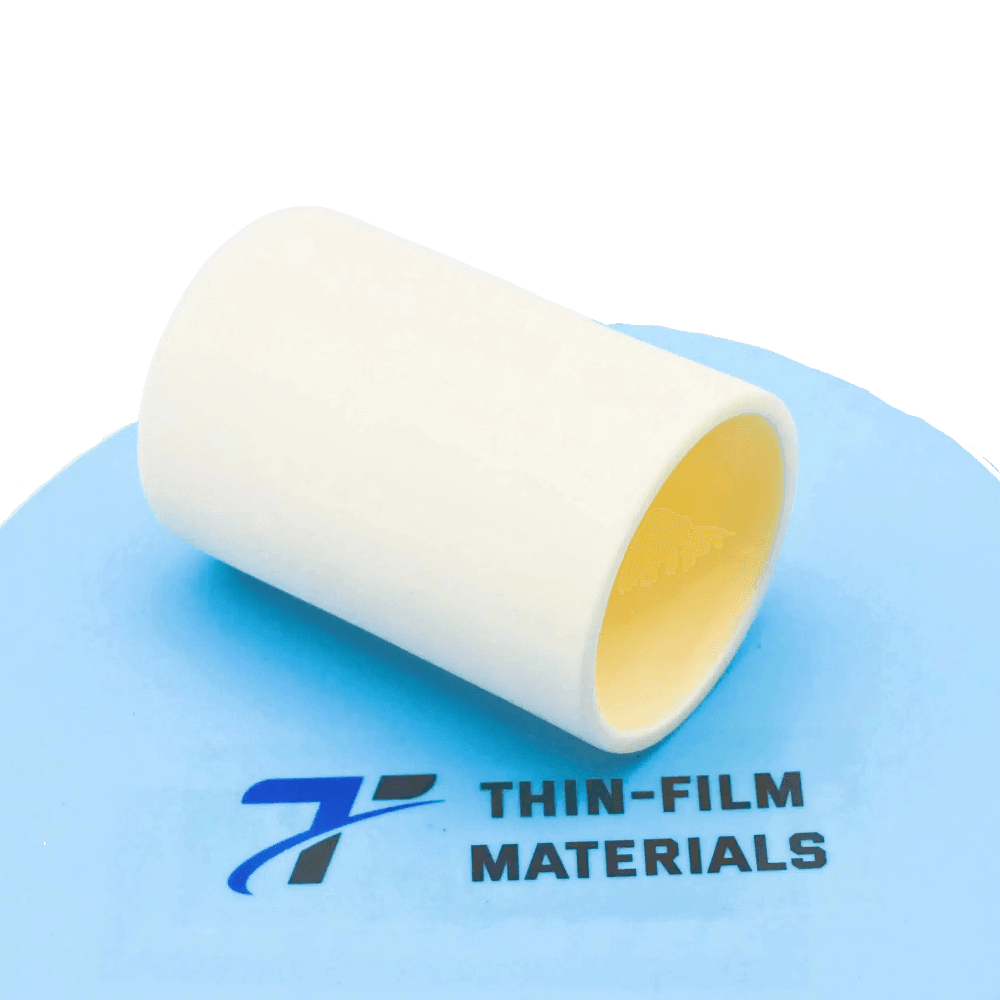

What Is an Alumina Crucible?

Alumina, or aluminum oxide (Al₂O₃), is a ceramic material known for its outstanding hardness, high melting point (~2050°C), and excellent electrical insulation properties. In crucible form, it is widely used in:

- Metallurgical sample preparation

- High-purity crystal growth

- Sintering processes

- Thermal analysis and differential scanning calorimetry (DSC)

Alumina crucibles are often manufactured using slip casting, isostatic pressing, or injection molding, followed by high-temperature sintering to achieve a dense, durable product. High-purity alumina (typically ≥99.7%) is favored for the most demanding applications.

What Is a Zirconia Crucible?

Zirconia, or zirconium dioxide (ZrO₂), is another refractory ceramic material recognized for its ultra-high melting point (~2700°C) and exceptional resistance to thermal shock. Its unique crystal structure allows for minimal thermal conductivity, making it a preferred choice for extreme temperature environments. Zirconia crucibles are frequently used in:

- Glass melting

- Platinum group metal casting

- High-temperature corrosion testing

- Aerospace material synthesis

Zirconia crucibles can also be stabilized with yttria (Y₂O₃) to improve their phase stability and resistance to thermal degradation, leading to the development of yttria-stabilized zirconia (YSZ), a common form used in industry.

High-Temperature Stability: Which Crucible Withstands Heat Better?

Alumina: A Reliable High-Temperature Performer

Alumina crucibles maintain structural integrity at temperatures up to 1700–1800°C for prolonged periods. They begin to soften around 1850°C and melt at approximately 2050°C. Their dimensional stability and resistance to thermal creep make them ideal for sintering and calcination tasks in ceramics and powder metallurgy.

However, alumina’s Achilles’ heel is its moderate thermal shock resistance. Rapid heating or cooling can cause cracking due to differential thermal expansion. Hence, temperature ramps must be carefully controlled during experiments.

Zirconia: The King of Extreme Temperatures

Zirconia crucibles outperform alumina in terms of melting point (2700°C) and thermal shock resistance. They can endure rapid temperature fluctuations without fracturing, which is crucial in processes like laser melting, induction heating, and arc welding crucible applications.

Their low thermal conductivity also helps maintain uniform heating of the sample, which is particularly beneficial in experiments involving volatile elements or precision melting.

SEO Note: If you’re searching for high-temperature crucibles for lab furnaces, zirconia might be your top contender.

Chemical Resistance: Which Material Is More Chemically Inert?

Alumina: Excellent Resistance to Most Chemicals

Alumina crucibles show remarkable chemical resistance to many acids and bases, especially under dry or low-temperature conditions. They are particularly resistant to:

- Hydrogen chloride (HCl)

- Hydrofluoric acid (with some caveats)

- Alkali salts

- Oxidizing environments

However, alumina can be attacked by strong acids and bases at elevated temperatures, particularly when molten fluxes or reactive elements like sodium or potassium are present. In reducing environments, the performance of alumina may also degrade over time.

Zirconia: Superior Inertness in Aggressive Environments

Zirconia crucibles outperform alumina in aggressive chemical environments, particularly at high temperatures. Zirconia resists corrosion by:

- Molten metals like platinum and nickel

- Acidic slags

- Alkaline earth oxides

- Strong oxidizers

Its stability in both acidic and basic media makes it invaluable in corrosive molten salt studies or high-temperature electrochemical cells.

SEO Tip: Researchers needing corrosion-resistant crucibles for molten salt experiments will often find zirconia crucibles to be the gold standard.

Mechanical Strength and Wear Resistance

Alumina: High Hardness, Moderate Toughness

Alumina is extremely hard (9 on the Mohs scale), but it is also brittle. Although it maintains shape well under mechanical stress, it is susceptible to fracture under impact or thermal stress. In static setups like laboratory muffle furnaces, this is usually not a problem. However, in high-vibration or transport-intensive settings, durability becomes a concern.

Zirconia: Tougher, Denser, More Impact-Resistant

Zirconia has a tetragonal crystal structure that undergoes a transformation toughening mechanism, giving it better fracture resistance than alumina. It’s one of the toughest ceramics available and can resist impact forces that would typically shatter an alumina crucible.

Its high density also contributes to wear resistance, making it an excellent choice for processes involving mechanical stirring, melting under induction, or grinding.

Thermal Shock Resistance: An Overlooked But Crucial Factor

Thermal shock resistance is often what determines crucible longevity in practical applications.

- Alumina has limited tolerance to rapid thermal change, especially when moving from cold to hot zones or vice versa. Cracking is common unless preheated gradually.

- Zirconia offers outstanding thermal shock resistance, making it suitable for intermittent use or applications where crucibles are exposed to fluctuating furnace temperatures.

For those searching Google for thermally stable crucibles for temperature cycling experiments, zirconia offers a safer, longer-lasting option.

Cost and Availability

Cost plays a significant role in materials selection, especially for large-scale or academic operations.

- Alumina crucibles are generally more affordable and readily available. Their lower price makes them a popular choice for routine laboratory use and disposable applications.

- Zirconia crucibles, while more expensive, offer longer lifespan in extreme conditions, often justifying the initial investment in demanding environments.

Pro tip: When budgeting for high-temperature laboratory supplies, consider not just the upfront cost, but also the potential savings in replacement frequency and failure rate.

Application Suitability: Choosing the Right Crucible for the Job

| Application | Recommended Crucible | Reason |

|---|---|---|

| Routine lab melting (<1700°C) | Alumina | Cost-effective, adequate thermal range |

| Melting platinum or precious metals | Zirconia | Resistant to metal corrosion, high melting point |

| Molten salt electrochemistry | Zirconia | Superior chemical stability |

| High-purity sintering | Alumina | Low cost, low contamination risk |

| Rapid thermal processing | Zirconia | Excellent thermal shock resistance |

Real-World Use Cases

Case 1: Ceramic Engineers in Spark Plasma Sintering

Spark plasma sintering (SPS) processes often require materials that can withstand fast ramp rates and high pressure. Alumina, in this context, may fracture under the intense thermal gradients. Many researchers report switching to yttria-stabilized zirconia crucibles to avoid failures and extend experiment consistency.

Case 2: Metallurgists Melting High-Value Alloys

In metallurgical operations where precious metals like platinum or iridium are melted, zirconia crucibles are essential. These metals can react with alumina, leading to contamination and material loss. Zirconia’s chemical inertness preserves both the crucible and the sample.

Environmental and Longevity Considerations

Alumina crucibles are easier to dispose of and have a lower environmental footprint during manufacturing. Zirconia production, particularly when stabilized with rare earths like yttria, involves more energy-intensive processes, although the longer operational life can offset some environmental impacts.

For labs pursuing green initiatives, choosing between the two requires evaluating lifecycle emissions, not just upfront energy costs.

Final Verdict: Alumina or Zirconia?

Choosing between alumina and zirconia crucibles depends heavily on your specific use case. Here’s a distilled guide:

- Choose alumina if:

- Your process temperatures are below 1800°C.

- You’re performing routine chemical analysis.

- Budget constraints are significant.

- Chemical environment is not overly aggressive.

- Choose zirconia if:

- You’re working at temperatures above 2000°C.

- The process involves rapid thermal cycling.

- You’re melting precious or reactive metals.

- Corrosive chemicals or molten salts are involved.

Conclusion: Precision Starts with the Right Crucible

In high-temperature material science, even the smallest detail—like crucible selection—can make or break an experiment. Whether you’re engaged in materials research, ceramic sintering, or metallurgical alloying, understanding the thermochemical behavior of crucible materials is essential.

Alumina crucibles continue to dominate for general-purpose use, offering a robust balance of performance, availability, and cost. Zirconia crucibles, while more expensive, deliver unparalleled thermal stability and chemical resistance, making them indispensable in extreme environments.

When searching for the best ceramic crucibles for high-temperature applications, consider not only the specifications but also the nature of your materials and goals. The more you align your crucible choice with your technical requirements, the better your outcomes will be