Micro-Electronic Basket Heaters

Tungsten basket heaters come in various shapes, allowing you to load material directly into the basket. Select a heater shape that closely fits the size of your substrate and suits the specific properties or form of the material you intend to heat. For repeated heating of the same material, these heaters can often be reused successfully multiple times.

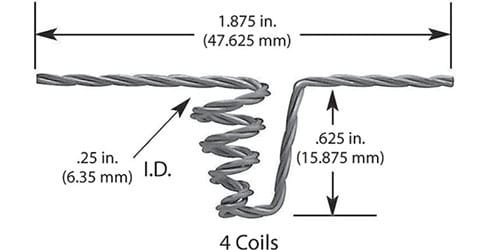

Tapered Helix

Tapered Helix (Tungsten)

#001: Tapered Helix (Tungsten), 4 Coils, 1 Wire x 0.030″ Dia., 5 Volt, 2.9 Amps, 23 Watts, 1800°C

#002: Tapered Helix (Tungsten), 4 Coils, 3 Wires x 0.025″ Dia., 5 Volt, 2.66 Amps, 42 Watts, 1800°C

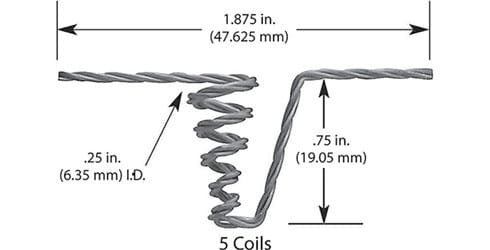

Tapered Helix (Tungsten)

5 Coils

#003: Tapered Helix (Tungsten), 5 Coils, 1 Wire x 0.030″ Dia., 5 Volt, 3.77 Amps, 87 Watts, 1800°C

#004: Tapered Helix (Tungsten), 5 Coils, 3 Wires x 0.025″ Dia., 5 Volt, 3.54 Amps, 152 Watts, 1800°C

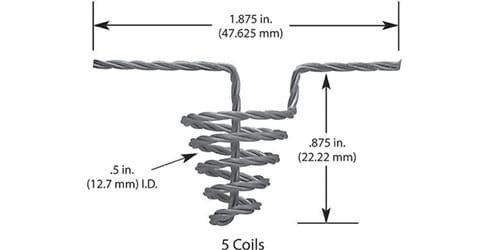

Tapered Helix (Tungsten)

5 Coils

#005: Tapered Helix (Tungsten), 5 Coils, 1 Wire x 0.040″ Dia., 5 Volt, 4.25 Amps, 136 Watts, 1800°C

#006: Tapered Helix (Tungsten), 5 Coils, 3 Wires x 0.025″ Dia., 5 Volt, 5 Amps, 220 Watts, 1800°C

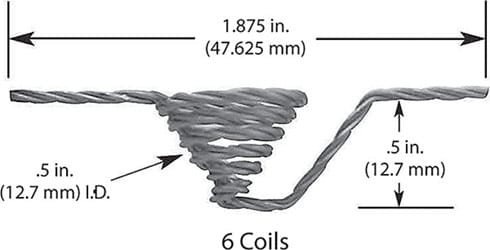

Tapered Helix (Tungsten)

6 Coils

#007: Tapered Helix (Tungsten), 6 Coils, 1 Wire x 0.030″ Dia., 5 Volt, 4.93 Amps, 108 Watts, 1800°C

#008: Tapered Helix (Tungsten), 6 Coils, 3 Wires x 0.025″ Dia., 5 Volt, 4.57 Amps, 183 Watts, 1800°C

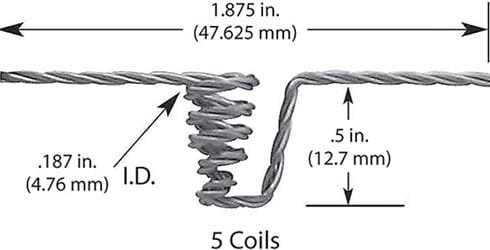

Tapered Helix Tight (Tungsten)

5 Coils

#009: Tapered Helix Tight (Tungsten), 5 Coils, 1 Wire x 0.030″ Dia., 5 Volt, 2.48 Amps, 57 Watts, 1800°C

#010: Tapered Helix Tight (Tungsten), 5 Coils, 3 Wires x 0.025″ Dia., 5 Volt, 2.3 Amps, 90 Watts, 1800°C

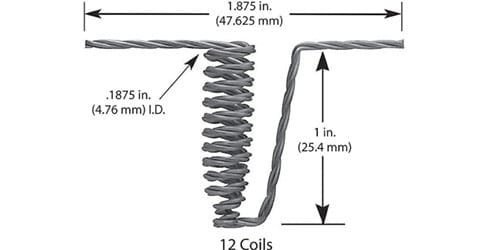

Tapered Helix Tight (Tungsten)

12 Coils

#011: Tapered Helix Tight (Tungsten), 12 Coils, 1 Wire x 0.030″ Dia., 5 Volt, 5.95 Amps, 125 Watts, 1800°C

#012: Tapered Helix Tight (Tungsten), 12 Coils, 3 Wires x 0.025″ Dia., 5 Volt, 5.51 Amps, 220 Watts, 1800°C

Frequently Asked Questions

What are micro‐electronics evaporation sources?

They are compact thermal evaporation sources designed for small-scale systems. Typically less than 2″ in length, these sources are optimized for low power deposition of thin films in microelectronic applications.

What materials are used to fabricate these sources?

Micro‐electronics sources are commonly made from tungsten for its high melting point and durability, with alternatives in tantalum and molybdenum. Some sources are also available with alumina coatings to prevent material wetting and alloying.

What applications are best suited for micro‐electronics evaporation sources?

They are ideal for thin film deposition in semiconductor devices, microelectromechanical systems (MEMS), and sample preparation, particularly when using expensive or small quantities of materials in research and R&D environments.

How do micro‐electronics sources differ from standard evaporation sources?

Micro‐electronics sources are smaller and require lower power, making them suitable for compact vacuum systems. They deliver precise control over deposition and are optimized for low-volume, high-precision applications.

What configurations are available in the micro‐electronics line?

The range includes micro‐electronic boats, thermal filaments, basket heaters, and shielded crucible heaters. These configurations allow for versatility in depositing various materials and adapting to specific system geometries.

Why is tungsten the material of choice?

Tungsten’s high melting point, low vapor pressure at high temperatures, and excellent thermal stability make it ideal for evaporation processes, ensuring high film quality and durability of the evaporation source.

How does an alumina coating benefit these sources?

Alumina coatings prevent wetting and alloying between the evaporant and the refractory metal, which enhances film uniformity, extends source life, and minimizes material loss during deposition.

What are the typical power requirements for micro‐electronics evaporation sources?

These sources are designed for low-power applications, often operating at voltages below 2–3 V and current levels tailored to their small dimensions. Exact requirements depend on the source design and the evaporant material.

What advantages do micro‐electronic sources offer for R&D?

Their small size and precise control allow researchers to deposit very thin, uniform films using minimal quantities of expensive materials. This is particularly beneficial for prototyping and iterative device development.

How are micro‐electronic evaporation sources integrated into existing systems?

They are designed to be compatible with standard vacuum chamber holders and low-power supply units, often featuring plug-and-play interfaces and documented power requirements to ensure seamless integration.

What are common troubleshooting tips for these sources?

Ensure the power supply matches the specified voltage/current, verify that the source is free of contamination, and check for proper alignment within the chamber. If deposition is non-uniform, consider using an alumina-coated version to minimize material wetting.

What are the primary advantages of micro-electronics evaporation sources?

Micro-electronics evaporation sources offer several key benefits:

Compact Size for Limited Spaces – These sources are typically less than 2 inches (50.8 mm) in length, making them ideal for systems with restricted space or low power availability.

High-Purity Film Deposition – By utilizing high-quality materials and precise control, these sources deposit films with minimal impurities, ensuring optimal device performance.

Versatility in Material Deposition – They accommodate a wide range of materials, including metals and dielectrics with high melting points, making them suitable for various applications.

Micro-Electronic Basket Heaters: Precision Heating Solutions for the Future of Micro-Electronics

With innovations continuously driving the need for more efficient and reliable coating techniques, ceramic sputtering targets have emerged as a significant material choice. Their unique properties—such as high thermal stability, excellent chemical resistance, and desirable electrical characteristics—make them indispensable in creating thin films with precise control over thickness, composition, and structure. In the following sections, we will address frequently asked questions and key topics that potential users, researchers, and industry professionals often search for online.

Table of Contents

Chapter 1

1. Introduction: What Are Micro-Electronic Basket Heaters and Why Are They Essential?

Micro-electronic basket heaters are specialized heating devices used to provide precise, controlled heat for various applications in micro-electronics. As the demand for miniaturized, high-performance electronic devices continues to grow, the need for consistent and reliable heating in the manufacturing process becomes paramount. Basket heaters are designed to offer this level of precision, making them essential in industries where even minor temperature fluctuations can result in defects or inefficiencies.

These heaters are typically employed to heat baskets or containers holding micro-electronic components during critical stages of production, such as soldering, assembly, and material deposition. Unlike traditional heating methods, micro-electronic basket heaters are engineered to provide uniform heat distribution across the entire surface area of the components they heat, which is crucial for maintaining the integrity and performance of sensitive micro-electronic parts.

Chapter 2

2. Why Are Micro-Electronic Basket Heaters Essential for Semiconductor Manufacturing?

In the semiconductor industry, micro-electronic basket heaters play a vital role in various stages of production, from wafer heating to crystal growth and material deposition. Semiconductor manufacturing is highly sensitive to temperature fluctuations, as even a slight variation in heat can lead to defects in the microcircuits, reducing yield and performance.

Basket heaters ensure uniform temperature distribution, which is essential for achieving consistent results in processes such as:

Wafer Heating: During the semiconductor production process, wafer heating is necessary to prepare them for photolithography, etching, and other critical steps. Basket heaters provide precise control over the temperature, ensuring that the wafers are heated evenly and to the correct temperature.

Crystal Growth: Basket heaters are used in the crystal growth process, where they maintain a stable and uniform environment for growing semiconductor crystals. This stability is crucial to avoid defects that can impact the electrical properties of the final product.

Material Deposition: Basket heaters also play a critical role in the deposition of thin films or coatings on semiconductor wafers. By maintaining consistent heat during deposition, these heaters help achieve the desired layer thickness and uniformity, both of which are vital for the performance of the microelectronics.

Overall, micro-electronic basket heaters are indispensable for optimizing yields, improving production efficiency, and ensuring the high performance of semiconductor products.

Chapter 3

3. How Do Micro-Electronic Basket Heaters Ensure Precision in Soldering and Micro-Electronics Assembly?

Soldering and assembly processes in micro-electronics require precise temperature control to avoid damaging delicate components. A small temperature fluctuation can lead to poor solder joints, reduced component performance, or even permanent damage. Micro-electronic basket heaters are designed to prevent such issues by providing a stable, uniform heat source.

These heaters are typically used to:

Solder Electronic Components: When assembling micro-electronic devices, components such as chips, resistors, capacitors, and connectors are soldered onto circuit boards. Basket heaters provide a consistent heat source to melt the solder and create reliable connections between the components. The ability to control the temperature precisely is critical to ensuring the strength and longevity of these connections.

Micro-Component Bonding: In addition to soldering, basket heaters are used to bond micro-components such as sensors, actuators, and other devices in the assembly process. The uniform heat distribution ensures that the bonding material flows evenly and sets properly, avoiding potential issues such as air pockets or uneven adhesion.

Assembly for Miniaturized Devices: As micro-electronic devices continue to shrink in size, the precision of the assembly process becomes even more critical. Micro-electronic basket heaters can heat small components evenly, ensuring that they are assembled accurately and efficiently without risk of thermal damage.

By providing an ideal heating environment, micro-electronic basket heaters are integral to the successful assembly and soldering of high-performance micro-electronic devices.

Chapter 4

4. What Are the Key Benefits of Micro-Electronic Basket Heaters for Material Testing?

Micro-electronic basket heaters are also commonly used in material testing, particularly for assessing how materials react to different temperatures. In the micro-electronics industry, materials need to perform consistently at high temperatures, whether they are part of a microprocessor, a circuit board, or any other electronic component.

High-Temperature Testing: Many micro-electronic materials, such as semiconductors, insulators, and conductive materials, need to be tested for their performance in high-temperature environments. Basket heaters provide a reliable and accurate means of testing material durability under extreme conditions. They ensure that the material is heated uniformly, preventing localized overheating that could skew test results.

Simulating Harsh Environments: Micro-electronic basket heaters are often used in laboratories to simulate harsh environmental conditions. Researchers can use these heaters to test how materials or components will perform in high-temperature environments, such as those found in automotive, aerospace, or defense applications.

Heat Resistance Testing: For materials that will be exposed to high heat in their end-use applications, such as those used in electronic packaging or high-power devices, basket heaters can be used to assess their long-term heat resistance. By subjecting materials to controlled heating cycles, manufacturers can evaluate their stability and performance at elevated temperatures.

In material testing, the consistency of temperature is crucial. Micro-electronic basket heaters provide the accuracy and reliability needed to test and develop materials for next-generation micro-electronics.

Chapter 5

5. How Do Micro-Electronic Basket Heaters Improve Efficiency in Vacuum Deposition and Thin-Film Manufacturing?

In micro-electronics, the deposition of thin films is a critical process used to apply various layers of materials onto substrates, such as semiconductors or circuit boards. The quality and consistency of these thin films are vital to the functionality of the final electronic devices. Micro-electronic basket heaters play a crucial role in ensuring the precision and effectiveness of vacuum deposition processes, such as Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD).

Controlled Heat During Thin-Film Deposition: Basket heaters provide a stable and uniform heat source that ensures the substrate is heated evenly before and during the deposition process. This controlled environment is essential for maintaining the uniformity of the film’s thickness and ensuring its adherence to the substrate.

Influence on Film Quality: The consistency of the heating process directly affects the quality of the thin films produced. Basket heaters help achieve better material conformity, reducing issues like film stress, delamination, or non-uniformity that can occur when heating is inconsistent.

Prevention of Overheating: Vacuum deposition processes often require extremely high temperatures, and precise control is needed to prevent overheating. Basket heaters are designed to maintain the correct temperature without causing damage to the substrate or the material being deposited, improving both efficiency and yield during production.

By maintaining consistent heating throughout the deposition process, micro-electronic basket heaters help ensure high-quality thin films that meet the strict requirements of micro-electronics and semiconductor industries.

Chapter 6

6. What Technological Features Make Micro-Electronic Basket Heaters Stand Out?

Modern micro-electronic basket heaters incorporate advanced technologies to meet the stringent requirements of today’s high-tech manufacturing processes. These heaters are designed not only for efficiency but also for reliability, accuracy, and safety.

Advanced Heating Elements: Micro-electronic basket heaters use a range of advanced heating elements, including ceramic materials and metal alloys, which are capable of withstanding high temperatures. Ceramic heating elements are commonly used for their excellent heat retention and uniform heating capabilities. Meanwhile, metal alloys, such as molybdenum or tungsten, are ideal for high-temperature applications due to their durability and conductivity.

Precision Temperature Control: These heaters often integrate digital controllers, sensors, and temperature regulation systems. By precisely controlling the temperature, they ensure that the micro-electronic components are heated evenly, without any risk of overheating. The use of thermocouples or infrared sensors further enhances the precision of temperature measurement and control.

Automation Integration: Many modern basket heaters can be connected to automated manufacturing systems, making them part of larger production lines. Automation ensures that the heating process is continuous and consistent, with minimal human intervention. This integration improves efficiency, reduces errors, and enhances overall productivity in high-volume manufacturing environments.

Safety Features: Given the critical nature of heating in sensitive environments, safety features such as overheat protection, alarm systems, and fail-safe mechanisms are built into most micro-electronic basket heaters. These features ensure that the heating process is not only efficient but also safe for operators and equipment.

The technological advancements in micro-electronic basket heaters make them indispensable for high-precision, high-volume micro-electronic manufacturing processes.

Chapter 7

7. How Can You Ensure Energy Efficiency and Cost Savings with Micro-Electronic Basket Heaters?

As industries focus more on sustainability and reducing operational costs, energy efficiency has become a key factor in the selection of manufacturing equipment. Micro-electronic basket heaters are no exception, and modern models are designed to offer substantial energy savings compared to traditional heating methods.

Efficient Heat Transfer: Micro-electronic basket heaters are designed to maximize heat transfer while minimizing energy consumption. The use of high-quality materials, such as advanced ceramics and alloys, ensures that the heater provides effective heat retention and uniform distribution, which means less energy is wasted. Additionally, many of these heaters feature insulation and advanced designs that reduce heat loss to the surrounding environment.

Long-Term Energy Savings: Because micro-electronic basket heaters are designed to provide precise temperature control, they can reduce energy consumption during operation. The precise control ensures that the heater only uses the energy needed to maintain the set temperature, avoiding unnecessary energy waste. This, in turn, lowers operating costs and reduces the environmental footprint of the manufacturing process.

Reduced Downtime and Maintenance Costs: The efficiency of modern micro-electronic basket heaters means that they are often more durable and reliable than older models. This translates to fewer breakdowns, less downtime, and reduced maintenance costs. Over the long term, the savings generated by fewer repairs and replacements can significantly offset the initial investment in these high-tech heating devices.

Overall, micro-electronic basket heaters help manufacturers improve their energy efficiency, reduce operating costs, and contribute to a more sustainable production process.

Chapter 8

8. What Are the Safety Features of Micro-Electronic Basket Heaters?

Given the high temperatures involved in many micro-electronic manufacturing processes, safety is paramount. Micro-electronic basket heaters are equipped with a range of safety features to protect both the equipment and the operators.

Overheating Protection: Many micro-electronic basket heaters come with built-in temperature monitoring systems that ensure the heater does not exceed a pre-set temperature limit. If the temperature rises beyond this limit, the system triggers an automatic shutdown or alarm, preventing potential damage to components or overheating-related hazards.

Fail-Safe Mechanisms: Advanced models of micro-electronic basket heaters are designed with fail-safe systems that provide a backup in case of a malfunction. For example, if the heater loses power or a sensor fails, the system may switch to a secondary heat source or immediately shut off to prevent accidents.

Built-in Alarms and Sensors: Temperature sensors and alarms help alert operators to any temperature anomalies, allowing them to take corrective action before problems escalate. These safety features are particularly crucial in high-volume production environments, where even a small error could result in a significant loss of materials or damage to equipment.

Operator Safety: In addition to the technical safety features, micro-electronic basket heaters are often designed with operator safety in mind. Features such as heat-resistant casing, user-friendly interfaces, and remote monitoring options help ensure that operators can safely manage the equipment and monitor its performance without exposure to high temperatures.

Safety is a key factor in the design and operation of micro-electronic basket heaters, ensuring that the heating process can be carried out smoothly and without risk to the operators or the equipment.

Chapter 9

9. How Do Micro-Electronic Basket Heaters Benefit Industries Beyond Electronics?

While micro-electronic basket heaters are primarily used in the electronics industry, their benefits extend to several other industries where precise, uniform heating is crucial for producing high-quality components. Here are a few industries that benefit from the capabilities of these advanced heating systems:

Automotive Industry: The automotive sector uses micro-electronic basket heaters for various applications, including the manufacturing of precision components, testing parts, and even in battery production. For instance, in electric vehicle (EV) battery production, these heaters ensure that battery components are properly heated during assembly and testing. The uniform heat distribution is critical to prevent uneven heating that could degrade battery performance.

Aerospace and Defense: In aerospace manufacturing, where parts must endure extreme conditions, micro-electronic basket heaters are used to test and process materials that will be exposed to high temperatures. These heaters help in the production of parts such as sensors, actuators, and other electronics used in aircraft and spacecraft, ensuring that components are robust and reliable under demanding conditions.

Medical Device Manufacturing: Micro-electronics play an important role in medical devices such as pacemakers, sensors, and imaging equipment. Micro-electronic basket heaters are used in the assembly of these components, ensuring that delicate medical devices are soldered and bonded accurately without overheating or damaging sensitive parts. The uniform heating ensures that these devices will perform reliably in the human body or clinical settings.

Nanotechnology and Materials Science: Researchers working with nanomaterials or in the field of material science benefit from the precise control provided by micro-electronic basket heaters. These heaters are used to simulate high-temperature environments and test the properties of new materials at the nanoscale. Whether it’s for coating applications or advanced material synthesis, precise heating is crucial for accurate results.

By providing precise and controlled heating, micro-electronic basket heaters enable high-quality manufacturing in industries far beyond electronics, expanding their utility to sectors that demand high precision and reliability.

Chapter 10

10. What Are the Different Types of Micro-Electronic Basket Heaters and Their Applications?

Micro-electronic basket heaters are available in various designs, each suited for specific applications. These heaters can be customized to meet the temperature, material, and size requirements of different industries and manufacturing processes. Here’s a look at the different types and their applications:

Standard Basket Heaters: These are designed for general use in industries such as electronics, automotive, and materials testing. They typically have a simple design and are capable of reaching high temperatures with good heat distribution. Standard models are ideal for applications like soldering, assembly, and general material heating.

High-Temperature Basket Heaters: For applications that require even higher temperatures, such as in semiconductor fabrication or aerospace manufacturing, high-temperature basket heaters are essential. These models are capable of reaching temperatures of over 1000°C, ensuring that even the most heat-sensitive materials are processed without risk of damage.

Custom Basket Heaters: Many manufacturers require specialized basket heaters tailored to their specific needs. Custom designs can be made to fit unique substrates, specific temperature ranges, or particular production environments. These heaters are often used in research and development settings where flexibility and precision are critical.

Compact or Miniature Basket Heaters: These heaters are designed for use in applications that require heating of smaller components or samples. Used in laboratories and for precise micro-manufacturing, compact basket heaters offer high precision in a small form factor, perfect for small-scale micro-electronic parts or testing materials at the nano level.

Automated Basket Heaters: Automated versions of micro-electronic basket heaters are integrated into fully automated manufacturing lines. These heaters are equipped with advanced controls and sensors, allowing for seamless operation within larger systems. Automated basket heaters are common in high-volume industries such as semiconductor production, where efficiency and consistency are paramount.

Each type of micro-electronic basket heater is engineered to meet the unique requirements of various applications, from general assembly to high-tech manufacturing processes, ensuring optimal performance in any setting.

Chapter 11

11. How to Choose the Right Micro-Electronic Basket Heater for Your Application?

Choosing the right micro-electronic basket heater depends on a variety of factors specific to your application. Here are the key considerations to make when selecting a heater for your process:

Temperature Range: The first thing to consider is the required temperature range for your application. Different materials and processes require different temperatures, so ensure the basket heater can reach and maintain the necessary temperature. High-temperature processes, such as those used in semiconductor manufacturing, may require heaters that can exceed 1000°C, while other applications may only need lower temperatures.

Material Compatibility: The materials you are heating will influence your choice of heater. Basket heaters are typically designed to accommodate materials like ceramics, alloys, and composites. Make sure the heating elements and the heater’s casing are compatible with the materials being heated to prevent corrosion, material degradation, or inefficiencies.

Size and Capacity: The size of the components or substrates being heated will determine the capacity of the heater. Larger components require heaters with greater size and power, while smaller components need more compact, precise heaters. Ensure the heater’s basket or chamber is large enough to accommodate your materials.

Heat Distribution: Uniform heat distribution is essential for many micro-electronic applications. Look for heaters that are specifically designed to provide even heating across the entire surface of the material. This ensures the consistent quality of the end product, whether you’re soldering components, testing materials, or depositing thin films.

Control and Automation Features: If your manufacturing process is part of an automated production line, you may want to choose a heater that integrates seamlessly with your existing systems. Features such as digital temperature controllers, automated sensors, and remote monitoring capabilities can improve efficiency and precision in your process.

Selecting the right micro-electronic basket heater involves a balance of these factors to ensure optimal performance and efficiency. By considering the unique demands of your application, you can find a heater that will enhance your manufacturing process and deliver the results you need.

Chapter 12

12. How to Maintain and Care for Micro-Electronic Basket Heaters for Optimal Performance?

Proper maintenance is essential for keeping your micro-electronic basket heater functioning at its best. Regular care ensures the heater remains efficient, durable, and safe to use. Here are some tips for maintaining your heater:

Routine Cleaning: Regularly clean the heating elements and baskets to remove any dust, debris, or residue that could impede heat transfer or cause overheating. Make sure to follow the manufacturer’s instructions for cleaning to avoid damaging sensitive parts.

Check Temperature Sensors and Controllers: The temperature sensors and controllers are crucial for maintaining precise heating. Ensure that these components are calibrated and functioning correctly. Periodic testing and calibration will help maintain temperature accuracy.

Inspect for Wear and Tear: Over time, the heating elements or insulation may degrade due to high temperatures and thermal cycles. Inspect the heater regularly for any signs of wear, such as cracks, discoloration, or damaged insulation. Replace any worn parts promptly to prevent malfunction.

Proper Storage and Handling: If the heater is not in use for an extended period, store it in a dry, cool place to avoid environmental damage. Handle the unit with care to prevent any mechanical damage that could affect its performance.

Troubleshooting Common Issues: If you notice that the heater is not reaching the desired temperature or is exhibiting erratic behavior, check the power supply, connections, and control settings. Sometimes, replacing a faulty thermostat or sensor can resolve issues and restore the heater’s functionality.

By following these maintenance practices, you can ensure that your micro-electronic basket heater operates efficiently, extending its lifespan and ensuring consistent performance over time.

Chapter 13

13. What Are the Future Trends and Innovations in Micro-Electronic Basket Heater Technology?

The technology behind micro-electronic basket heaters is constantly evolving to meet the growing demands of industries such as semiconductor manufacturing, automotive, and aerospace. As production processes become more automated and precision-driven, basket heaters are adapting to integrate new technologies and improve efficiency. Here are some key future trends and innovations in this field:

Integration with Industry 4.0: The advent of Industry 4.0—the fourth industrial revolution—brings a focus on automation, data exchange, and smart manufacturing. In the future, micro-electronic basket heaters will be increasingly integrated with automated systems that use Internet of Things (IoT) technology for real-time monitoring and control. This will allow manufacturers to track temperature fluctuations, monitor energy consumption, and make adjustments remotely to optimize the heating process.

Smart Sensors and Artificial Intelligence (AI): The integration of smart sensors and AI into micro-electronic basket heaters will enable them to automatically adjust temperature and heating cycles based on environmental variables and real-time feedback. This innovation will not only enhance heating precision but also contribute to predictive maintenance, allowing manufacturers to identify potential issues before they cause failures.

Energy-Efficient Designs: With growing concerns about energy consumption and sustainability, future micro-electronic basket heaters will feature even more energy-efficient designs. Advanced insulation materials, improved heating elements, and better heat retention systems will allow heaters to consume less power while maintaining high performance. Manufacturers will prioritize energy-efficient solutions to reduce operational costs and minimize their environmental footprint.

Advanced Materials: As material science advances, micro-electronic basket heaters will incorporate more heat-resistant, durable materials that can withstand extreme operating conditions. New materials such as graphene-based coatings or nano-structured composites may be used in the construction of these heaters to improve their heat conductivity, longevity, and overall performance.

Customization and Flexibility: As the demand for tailored solutions grows, we can expect micro-electronic basket heaters to become more customizable. Manufacturers will be able to specify exact temperature ranges, heater designs, and control systems to meet the unique needs of specific applications, such as 5G manufacturing, quantum computing, and next-gen electronics.

Integration with Cleanroom Technology: In industries such as semiconductor manufacturing and aerospace, cleanliness is paramount. Future micro-electronic basket heaters will be designed to operate efficiently within cleanroom environments. This will include features such as non-contaminating materials, sealed units to prevent particle exposure, and advanced filtration systems to ensure that the heating process does not compromise cleanliness standards.

The continued innovation in micro-electronic basket heaters will undoubtedly lead to smarter, more efficient, and more sustainable heating solutions, allowing industries to meet the challenges of the future.

Chapter 14

Frequently Asked Questions

How long do micro-electronic basket heaters typically last?

What is the ideal temperature range for micro-electronic basket heaters?

Can these heaters be used for applications outside micro-electronics?

How can I improve the energy efficiency of my micro-electronic basket heater?

Are micro-electronic basket heaters customizable for specific applications?

What maintenance is required for micro-electronic basket heaters?

What industries use micro-electronic basket heaters?

Can micro-electronic basket heaters be used in cleanroom environments?

Chapter 15

14. Conclusion: Why Micro-Electronic Basket Heaters Are the Future of Precision Heating

Micro-electronic basket heaters are essential components of modern manufacturing processes across a variety of industries. From semiconductor production to material testing and micro-electronics assembly, these heaters ensure precision, reliability, and efficiency in high-performance environments. As technology continues to evolve, micro-electronic basket heaters will remain a critical tool for driving advancements in manufacturing processes and supporting the development of cutting-edge technologies.

By offering energy-efficient, customizable, and precise temperature control, micro-electronic basket heaters play an indispensable role in industries that require high precision, from aerospace to medical device manufacturing. As we move forward, the integration of automation, AI, and sustainable design will further enhance the capabilities of these heaters, enabling manufacturers to meet the increasing demands of modern production.

For businesses looking to improve efficiency, precision, and reliability in their manufacturing processes, micro-electronic basket heaters are the future of precision heating. TFM is committed to providing customized solutions and expert support to meet the diverse needs of industries requiring high-quality heating systems. Whether you are in semiconductor manufacturing, automotive, or aerospace, we have the expertise to provide the perfect heater for your application.