Introduction

Thulium oxide (Tm₂O₃) is a rare earth compound that has found increasing importance in various high-tech applications, especially in thin film deposition. When fabricated into a sputtering target, thulium oxide becomes a vital material for producing high-performance films with unique optical, magnetic, and thermal properties. This article explores the major applications of thulium oxide sputtering targets, their significance in scientific research and industry, and the unique benefits they bring to next-generation material design.

Overview of Thulium Oxide (Tm₂O₃)

Thulium is one of the least abundant rare earth elements, but its oxide form is highly stable and exhibits valuable properties such as:

- High melting point (2345°C)

- Optical transparency in the infrared spectrum

- Magnetic characteristics at low temperatures

- Chemical and thermal stability

These properties make Tm₂O₃ highly suitable for deposition via sputtering to form thin films used in demanding environments and high-performance optical/electronic components.

1. Infrared Optical Coatings

One of the most significant applications of thulium oxide sputtering targets is in infrared (IR) optical coatings. Due to its high refractive index and low absorption in the infrared range, Tm₂O₃ is used to create:

- Anti-reflective coatings for IR sensors, cameras, and lenses.

- Beam splitters and filters that selectively pass or block IR wavelengths.

- Laser protective coatings for optics used in medical, military, and telecommunications equipment.

In multilayer thin film stacks, Tm₂O₃ is often alternated with low-index materials (like SiO₂) to achieve optimal performance across target wavelength bands (e.g., 1.47–2.1 μm).

2. Thin Film Laser Materials

Thulium-doped materials are known for their emission in the near-infrared range, especially around 1.9–2.1 µm, which is ideal for:

- Diode-pumped solid-state lasers

- Medical laser systems (e.g., urology, dermatology)

- Eye-safe LIDAR systems

- Fiber laser amplifiers

When deposited as thin films, thulium oxide enables precise control over the concentration and distribution of Tm ions. This allows researchers and manufacturers to tailor laser gain media with specific emission wavelengths and pulse characteristics.

3. Functional Ceramics and Dielectric Films

Tm₂O₃ is widely utilized in the development of functional oxide ceramics, where it acts as a dopant to modify electrical and dielectric properties.

- In MLCCs (Multilayer Ceramic Capacitors), thulium oxide is used to improve the thermal and frequency stability of BaTiO₃-based dielectrics.

- Ferroelectric thin films, such as those based on lead zirconate titanate (PZT), can be doped with Tm₂O₃ to enhance fatigue resistance and switching behavior.

- In piezoelectric sensors and actuators, Tm₂O₃ thin films improve electromechanical coupling efficiency.

This makes Tm₂O₃ sputtering targets crucial in electronics miniaturization and high-frequency applications like 5G and automotive radar.

4. Magneto-Optical Materials

Due to the presence of unpaired 4f electrons, thulium ions exhibit magnetic dipole behavior. Thin films deposited using thulium oxide targets are being studied for:

- Magneto-optical Kerr effect (MOKE) devices.

- Magnetic memory media, especially in combination with Fe, Co, or Dy to enhance coercivity and thermal stability.

- Quantum spintronic devices, where Tm ions contribute to low-temperature quantum behavior.

These applications are still in the development stage but show promise for future computing and storage technologies.

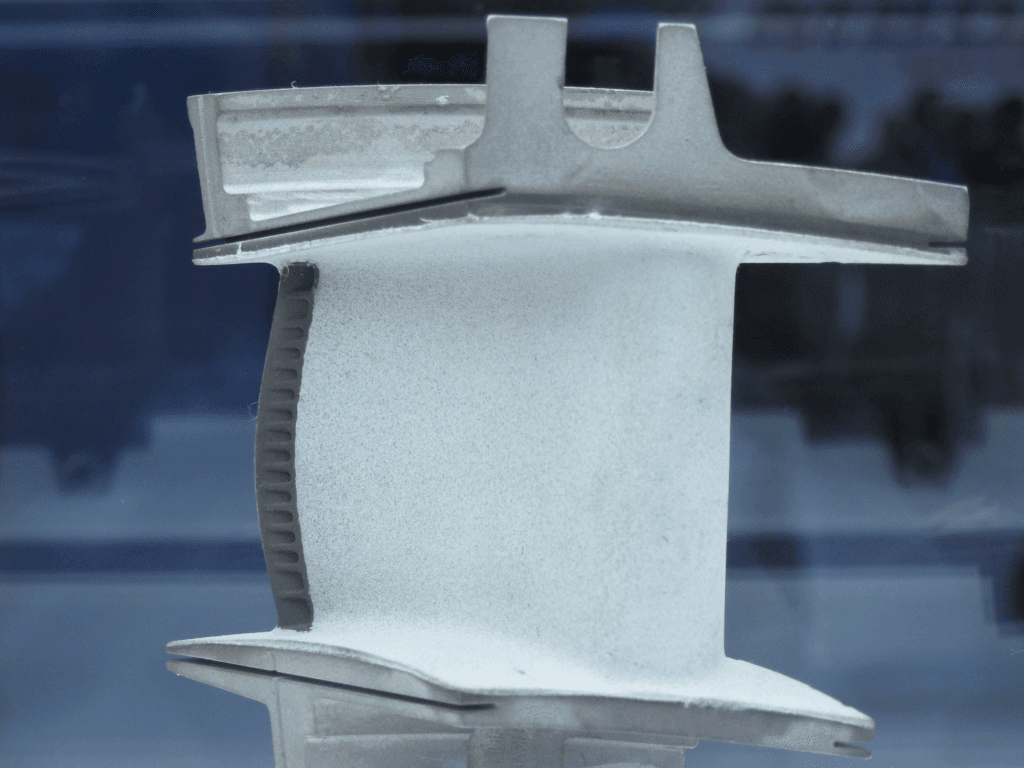

5. Thermal Barrier Coatings (TBCs)

In aerospace and power generation industries, thermal barrier coatings are essential for protecting engine components from extreme temperatures.

Tm₂O₃ has emerged as a candidate material for:

- High-temperature ceramic coatings, where it can be used alone or in solid solutions (e.g., with ZrO₂).

- Enhancing the phase stability of traditional YSZ (yttria-stabilized zirconia) coatings.

- Improving oxidation resistance and thermal conductivity control of coatings used in turbines and space applications.

These coatings are often deposited via reactive sputtering or co-sputtering, where Tm₂O₃ sputtering targets offer excellent performance.

6. Transparent Conductive Film (TCF) Research

Though not inherently conductive, thulium oxide can serve as a dopant in transparent conductive oxides (TCOs) such as ZnO or In₂O₃. This enables:

- Bandgap engineering to improve optical transparency.

- Carrier concentration tuning for improved conductivity.

- Enhanced thermal and chemical durability of TCO thin films.

This is particularly useful in:

- Display technologies (LCD, OLED)

- Solar cells (as front electrode films)

- Transparent electronics and sensors

7. Quantum and Photonic Materials

With the growing interest in quantum materials and integrated photonics, thulium oxide is finding new applications as a dopant or host matrix in:

- Rare-earth-doped waveguides for quantum communication.

- Photoluminescent thin films for photonic circuits.

- Optical memory devices, where thulium’s energy levels can be manipulated for long-lived quantum states.

Sputtered Tm₂O₃ thin films allow researchers to control thickness, uniformity, and stoichiometry at the nanoscale — a key requirement for photonic integration.

8. Academic and Experimental Research

As a rare and relatively less-studied material, Tm₂O₃ sputtering targets are also frequently used in research settings, including:

- Material science studies on rare-earth thin film behavior.

- Exploration of multi-component oxides for complex heterostructures.

- Thin film growth dynamics and crystal orientation studies using PLD or RF sputtering.

Such research often lays the foundation for future industrial-scale applications.

Benefits of Using Thulium Oxide Sputtering Targets

Using Tm₂O₃ in sputtering form provides numerous advantages:

| Feature | Benefit |

|---|---|

| High Purity (≥99.99%) | Reduces contamination in thin films |

| Stable Oxide Form | Ensures predictable stoichiometry and film structure |

| Good Adhesion | Helps produce films with excellent mechanical strength |

| Compatibility with RF Sputtering | Allows deposition on delicate or temperature-sensitive substrates |

| Tunable Film Properties | Enables precise optical and electronic design |

Industries That Benefit from Thulium Oxide Targets

- Aerospace & Defense: IR coatings, TBCs, laser systems

- Medical: Thulium laser devices for surgical use

- Telecommunications: Optical amplifiers, fiber laser systems

- Consumer Electronics: Advanced display components

- Energy: Transparent conductive films in solar and smart glass

- Academic Institutions: Fundamental studies of rare earth materials

FAQs About Thulium Oxide Sputtering Targets

- What is a Thulium Oxide (Tm₂O₃) sputtering target used for?

Thulium oxide targets are used in thin film deposition processes for infrared optics, laser materials, semiconductors, and high-performance coatings. - What are the key properties of Thulium Oxide that make it suitable for sputtering?

Tm₂O₃ has high thermal stability, good infrared transparency, a moderate atomic weight, and compatibility with other rare earths—making it ideal for specialized optical and electronic coatings. - What deposition methods can be used with Thulium Oxide targets?

They are commonly used in RF magnetron sputtering and pulsed laser deposition (PLD), and occasionally in e-beam evaporation with proper crucible and temperature controls. - Is Thulium Oxide conductive or insulating?

Thulium oxide is a dielectric (insulator) with low electrical conductivity, making it suitable for optical and insulating layers in multilayer devices. - What are the typical purity levels available for Tm₂O₃ sputtering targets?

Standard purities range from 99.9% to 99.99% (3N to 4N), depending on the application requirements, especially in optics and electronics. - Can Thulium Oxide targets be customized in size and shape?

Yes. Manufacturers typically offer customization in diameter, thickness, backing plates (for bonding), and configuration (planar, circular, rectangular). - What industries commonly use Thulium Oxide sputtering targets?

Common sectors include infrared optics, defense & aerospace, laser systems, telecommunications, and research laboratories. - Are Thulium Oxide targets compatible with other rare earth materials in co-sputtering?

Yes, they are often used alongside Yttrium, Erbium, or Holmium oxides for co-doping optical films or developing custom rare-earth-based thin films. - How should Thulium Oxide targets be stored or handled?

They should be stored in a dry, clean environment, away from moisture. Although relatively stable, prolonged exposure to humidity should be avoided. - What is the difference between sintered and hot-pressed Tm₂O₃ targets?

Sintered targets are more common, offering good density and performance. Hot-pressed ones provide higher density and better structural integrity, suitable for high-energy sputtering systems. - Can Thulium Oxide targets be bonded for high-power sputtering applications?

Yes, elastomeric or indium bonding is typically used to attach the ceramic target to a backing plate (usually copper or molybdenum). - Are there safety concerns when using Thulium Oxide in sputtering systems?

Thulium compounds are considered to have low toxicity, but general powder and sputtering target handling precautions—like proper ventilation and PPE—are recommended. - How does Thulium Oxide compare to other rare earth oxides like Y₂O₃ or Er₂O₃ in optical films?

Tm₂O₃ offers unique optical properties in the near-IR region (around 1.9–2.0 μm), making it preferable for specific laser and optical amplification applications.

Conclusion

Thulium oxide sputtering targets represent a specialized but increasingly valuable material for advanced thin film fabrication. Their use in optical coatings, laser materials, magneto-optical devices, and high-temperature ceramics underscores their growing relevance in both research and industry. As technologies evolve and the demand for high-performance films increases, Tm₂O₃ will continue to be a material of interest for next-generation innovations.

For manufacturers and research labs seeking high-purity, customizable sputtering targets, thulium oxide offers a powerful solution with broad applicability across multiple high-tech fields.