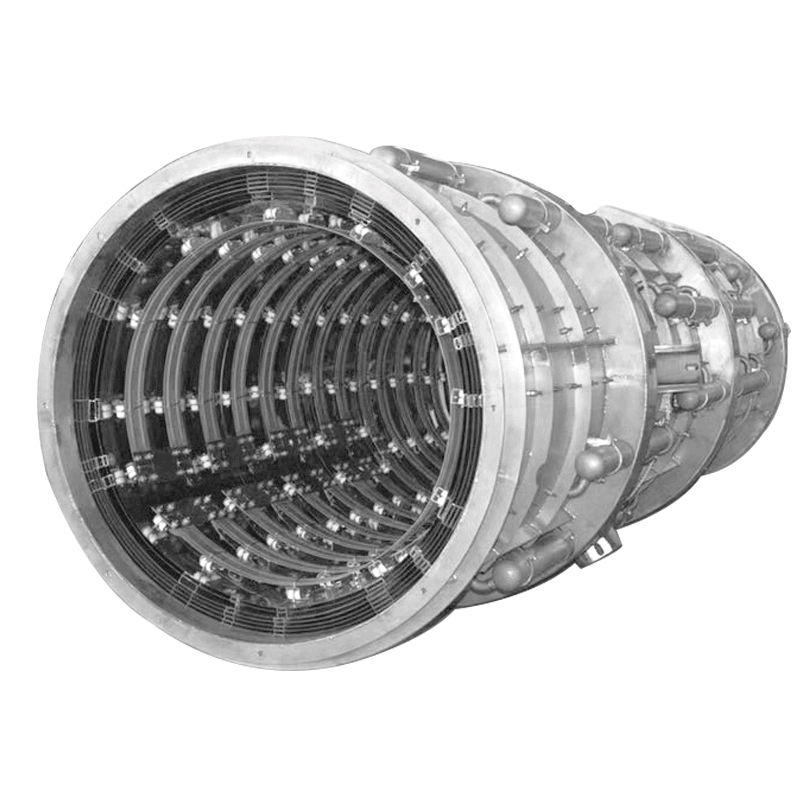

Molybdenum Vacuum Furnace Chamber

Molybdenum Vacuum Furnace Chamber

Molybdenum Vacuum Furnace Chambers are designed for high-temperature vacuum applications, utilizing molybdenum’s exceptional thermal and mechanical properties. They ensure oxidation-free processing, making them ideal for critical processes like sintering, brazing, and heat treatment. These chambers enable precise temperature control, which is essential for producing high-quality components.

Thin Film Materials Engineering (TFM) specializes in advanced thin-film products and vacuum furnace solutions, providing a wide range of materials and expertise to optimize production processes and deliver superior project outcomes.

Product Specifications

Introduction

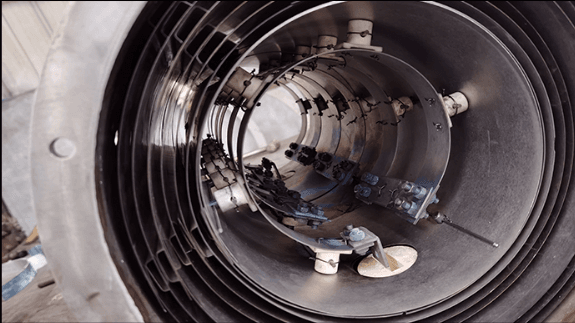

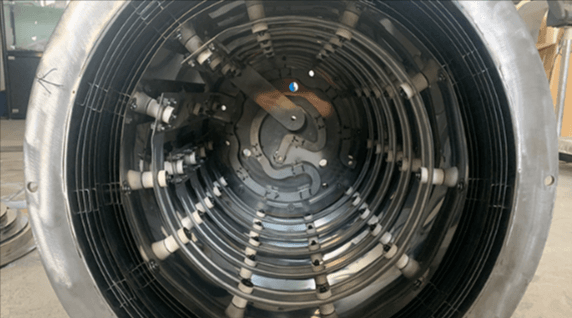

The Molybdenum Vacuum Furnace Chamber is a core structural component used in high-temperature vacuum and controlled-atmosphere furnaces. Owing to molybdenum’s high melting point, excellent thermal conductivity, and low vapor pressure, molybdenum chambers are widely adopted in sintering, brazing, annealing, and crystal growth processes where cleanliness, dimensional stability, and thermal uniformity are critical.

Detailed Description

Molybdenum vacuum furnace chambers are fabricated from high-purity molybdenum sheets or plates through precision forming, welding, and stress-relief processes. The material maintains excellent mechanical strength and structural integrity at elevated temperatures, making it well suited for repeated thermal cycling in vacuum or inert gas environments.

Compared with stainless steel or graphite furnace chambers, molybdenum offers:

Superior high-temperature resistance, enabling stable operation well above 1600 °C

Low vapor pressure, minimizing contamination of processed materials

Excellent thermal conductivity, supporting uniform temperature distribution

Good chemical compatibility, especially with refractory metals and ceramics

Chambers can be supplied as cylindrical or box-type structures, with customized wall thicknesses, flanges, ports, and internal features to integrate seamlessly with existing vacuum furnace systems.

Applications

Molybdenum vacuum furnace chambers are commonly used in:

High-temperature vacuum sintering and hot pressing

Vacuum brazing of aerospace and electronic components

Heat treatment of refractory metals and alloys

Semiconductor and electronic materials processing

Crystal growth and advanced materials research

Technical Parameters

| Parameter | Typical Value / Range | Importance |

|---|---|---|

| Material | Molybdenum (Mo) | Provides high-temperature structural stability |

| Purity | 99.95% – 99.99% | Reduces contamination and outgassing |

| Maximum Working Temperature | Up to ~1800–2000 °C (vacuum/inert) | Suitable for high-temperature furnace operation |

| Density | ~10.2 g/cm³ | Ensures mechanical strength |

| Fabrication | Formed & welded Mo sheets | Allows large, complex chamber designs |

| Environment | Vacuum / Inert gas | Prevents oxidation at high temperatures |

Comparison with Related Furnace Chamber Materials

| Material | Key Advantage | Typical Application |

|---|---|---|

| Molybdenum (Mo) | High-temperature strength, low vapor pressure | Vacuum sintering, brazing |

| Tungsten (W) | Higher melting point | Ultra-high-temperature furnaces |

| Graphite | Lightweight, thermal shock resistance | Non-oxidizing furnaces |

| Stainless Steel | Easy fabrication, low cost | Low–medium temperature furnaces |

FAQ

| Question | Answer |

|---|---|

| Can the furnace chamber be customized? | Yes, dimensions, thickness, ports, and mounting interfaces can be fully customized. |

| Is molybdenum suitable for use in air? | No, molybdenum oxidizes at high temperatures and must be used in vacuum or inert gas. |

| What joining methods are used? | Precision welding and mechanical fastening designed for high-temperature stability. |

| Is this suitable for industrial-scale furnaces? | Yes, molybdenum chambers are widely used in both laboratory and industrial vacuum furnaces. |

Packaging

Our Molybdenum Vacuum Furnace Chambers are carefully inspected, tagged, and labeled to ensure traceability and quality control. Each chamber is securely packed with protective materials and moisture control measures to prevent damage or oxidation during storage and international transportation.

Conclusion

The Molybdenum Vacuum Furnace Chamber provides a reliable, high-performance solution for demanding high-temperature vacuum furnace applications. With high purity, excellent thermal stability, and full customization options, it supports consistent processing in advanced industrial and research environments.

For detailed specifications and a quotation, please contact us at sales@thinfilmmaterials.com.

Product Cases

Applications

Tungsten Brackets are primarily used in the vacuum furnace industry, where they play a key role in holding components or fixtures within the furnace chamber. Some specific applications include:

- Heat treatment of metals and alloys.

- Crystal growth processes for semiconductors.

- Sintering of advanced ceramics and powdered metals.

- Brazing and annealing in controlled atmospheres.

Customization

At TFM, we understand that no two vacuum furnace setups are the same. That’s why we offer custom Tungsten Brackets tailored to your specific design requirements, including:

- Precise dimensions and tolerances.

- Specialized coatings to enhance performance.

- Custom geometries to fit unique chamber designs.

Our team works closely with you to deliver the perfect solution, ensuring optimal performance and longevity in your vacuum furnace.

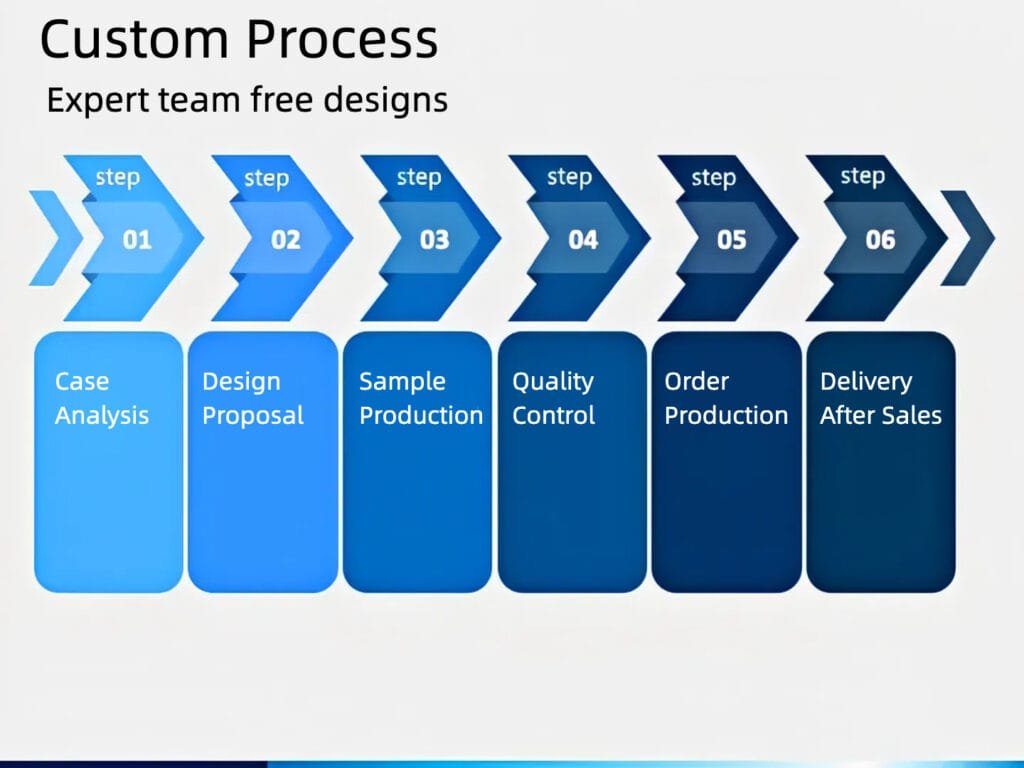

Why TFM

Our Advantages

FACTORY DIRECT SALE

GENUINE MATERIALS

SUPPORT FOR CUSTOM

VARIED SPECIFICATIONS

DETAILS OF THE FINE

INTIMATE AFTER-SALES