Molybdenum Tube

Molybdenum Tube for Industrial and High-Temperature Applications

Molybdenum / TZM Capillary (Moly / TZM Capillary)

Material: Molybdenum, Mo-1, Mo-2 or TZM Alloy

Purity: 99.95% Min

Standard: ASTM B386

Size Range: OD0.5mm / 0.02″ Min. * Wall Thick 0.1mm / 0.012″ Min. * Tailored Length

Surface: Polished(Ra<3.2), Chemical Cleaned

Other: Sintered to be Unibody, No Bonding

- Molybdenum and TZM (Titanium Zirconium Molybdenum) capillary tubes have a variety of applications across different industries due to their unique properties, including high melting points, excellent thermal conductivity, and corrosion resistance.

Aerospace and Defense

In the aerospace sector, molybdenum and TZM tubes are utilized for components that must endure extreme temperatures and pressures, such as rocket nozzles and heat shields. Their strength and durability make them ideal for structural components in aircraft and missiles, ensuring long-lasting performance in harsh environments.

Energy and Power Generation

These materials are critical in the energy sector, particularly in nuclear power plants, where they are used for reactor components and fuel rods. Their high thermal conductivity and resistance to radiation damage enhance operational efficiency. Additionally, they are employed in fossil fuel power plants for boiler tubes and heat exchangers, as well as in solar power systems to improve energy efficiency.

Manufacturing and Industrial Processes

Molybdenum and TZM capillary tubes are essential in high-temperature furnaces, serving as heating elements and structural supports. They are also used in glass production, where their resistance to corrosion by molten glass makes them suitable for components like stirrers and melting electrodes.

Electronics and Semiconductor Industry

These capillary tubes are employed in semiconductor manufacturing, particularly in processes like molecular beam epitaxy, where their stability at high temperatures is crucial for the deposition of materials.

Medical Applications

Molybdenum and TZM tubes can also be found in medical devices, particularly in X-ray tubes and other imaging equipment, where their ability to withstand high temperatures and mechanical stress is beneficial.

Overall, the applications of molybdenum and TZM capillary tubes are diverse, spanning critical industries that require materials capable of performing under extreme conditions.

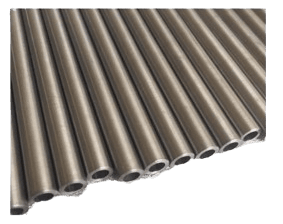

Molybdenum Tube & Pipe (Moly Tubing)

Material: Molybdenum (Mo), Mo-1, Mo-2

Purity: 99.95% Min

Standard: ASTM B386

Size Range: Diameter 0.5~600mm, Wall Thick 0.1~30mm, Length 5~6,000mm

Surface: Polished(Ra<3.2), Chemical Cleaned

Other: Sintered to be Unibody, No Bonding

Product | Outer Diameter (mm) | Wall Thickness (mm) | Length (mm) | |||

|---|---|---|---|---|---|---|

Size | Tolerance | Size | Tolerance | Size | Tolerance | |

Molybdenum Tube/Pipe | <100 | ±1.0 | <1 | ±0.1 | <100~150 | ±2.0 |

100~200 | ±2.0 | 1~3 | ±0.25 | 150~350 | ±3.0 | |

200~300 | ±3.0 | 3~10 | ±0.5 | 350~650 | ±4.0 | |

300~400 | ±5.0 | 10~20 | ±1.0 | 650 ~ 2000 | ±5.0 | |

>400 | ±7.0 | 20 ~ 30 max | ±1.0 | 2000 ~ 6000 max | ±5.0 | |

Titanium-Zirconium-Molybdenum Alloy (TZM) Tube & Pipe

Material: TZM Alloy

Density: ≥10.05g/cm3

Tensile Strength: ≥735MPa

Yield Strength: ≥685MPa

Elongation: ≥10%

Hardness: HV240-280

Size Range: 0.5~400mm Diameters, Wall Thick 0.1~30mm, Length 5~6,000mm

Surface: Polished(Ra<3.2), Chemical Cleaned

Molybdenum Lanthanum (Mo-La) Alloy Tube & Pipe

Material: Molybdenum Lanthanum Alloy, La2O3: 0.3~0.7%

Size: Diameter 0.8”~20”, Length ≤106”

Standard: ASTM B386, ASTM B387

Surface: Rolling Surface, Chemical Cleaned, Polished, Grinding

TFM offers Molybdenum Tubes and Pipes in both seamless and welded options. Our prices are factory-direct competitive, and our products are of high quality. We have a wide range of standard sizes available, but if you don’t see the size you need, just let us know, and we’ll be happy to help.

Molybdenum Tube TZM Capillary Tubes Video

Molybdenum Tubing Properties (Theoretical)

| Molecular Weight | 95.94 |

|---|---|

| Appearance | Silvery |

| Melting Point | 2,623 °C |

| Boiling Point | 4,639 °C |

| Density | 10,280 kg/m3 |

| Solubility in H2O | N/A |

| Electrical Resistivity | 5.2 microhm-cm @ 0 °C |

| Electronegativity | 1.9 Paulings |

| Heat of Fusion | 6.6 Cal/gm mole |

| Heat of Vaporization | 128 K-Cal/gm atom at 4612 °C |

| Poisson’s Ratio | 0.31 |

| Specific Heat | 0.0599 Cal/g/K @ 25 °C |

| Tensile Strength | N/A |

| Thermal Conductivity | 1.38 W/cm/K @ 298.2 K |

| Thermal Expansion | (25 °C) 4.8 µm·m-1·K-1 |

| Vickers Hardness | 1,530 MPa |

| Young’s Modulus | 329 GPa |

Discription

A Molybdenum Tube or Molybdenum Pipe is a cylindrical structure made from the metal molybdenum. Molybdenum Tubes and Pipes can be used at service temperatures up to 1,800 degrees Celsius. They can serve by producing quartz tubing and quartz or glass melting. Moly tubes are essential in making quartz tubing and melting quartz and glass. They are also used in making electron tube parts, heaters in high-temperature furnaces, and thermocouple holders.

TFM specializes in supplying Molybdenum and TZM tubes and capillaries and has extensive experience manufacturing high-performance materials, particularly molybdenum and its alloys. These advanced materials are crucial for addressing the glass industry’s complex needs, supporting processes such as feeding, melting, homogenizing, and shaping glass products.

Molybdenum Tube/Pipe Applications

- 1.High-Temperature Furnaces:

- Molybdenum tubes are used in the construction of high-temperature furnaces, where they can withstand extreme heat, such as quartz melting.

- 2.Heat Exchangers:

- Molybdenum tubes and pipes are applied in the manufacturing of heat exchangers for efficient heat transfer in various industrial processes.

- 3.Electronic and Semiconductor Industry:

- Utilized in the electronics and semiconductor industry for specific components requiring high thermal conductivity.

- 4.Aerospace and Defense:

- Molybdenum tubes and pipes find applications in the aerospace and defense sectors for components that must endure high temperatures.

- 5.Medical Equipment:

- In certain medical applications, molybdenum tubes and pipes may be used for specialized purposes due to their unique properties.

- The specific application of Molybdenum Tubes can vary based on their dimensions, purity, and the specific requirements of the industry or process. Molybdenum Tubes play a crucial role in industries that require materials capable of withstanding extreme temperatures and demanding conditions.

Molybdenum Tubes and Pipes Packaging

Our Molybdenum Tubes & Pipes are meticulously tagged and externally labeled, ensuring both efficient identification and rigorous quality control. We prioritize utmost care to prevent any potential damage that may occur during storage or transportation.