Tungsten Bracket

Tungsten Bracket

At Thin Film Materials Engineering (TFM), we specialize in manufacturing Tungsten Brackets—critical components used in vacuum furnace chambers. Tungsten is the material of choice for such applications due to its unique properties, including high melting point, strength, and corrosion resistance. These characteristics make Tungsten Brackets essential for demanding environments like high-temperature vacuum furnaces used in industries such as aerospace, metallurgy, and semiconductor manufacturing.

Explore high-quality Tungsten Brackets from TFM to meet your specific industrial needs.

Product Specifications

| Specification | Details |

|---|---|

| Brand | TFM |

| Specification | Customized as needed |

| Place of Origin | China |

| Material | Tungsten and its alloys |

| Application | It is widely used in the vacuum coating industry and in industries involving sintering furnaces for sintering or vacuum annealing. |

Why Tungsten?

Tungsten (W) has a melting point of 3,422°C (6,192°F), making it one of the highest melting point metals available. This allows Tungsten Brackets to withstand extreme temperatures that are commonly reached in vacuum furnaces. Additionally, tungsten offers:

- Excellent thermal conductivity for consistent heat distribution.

- High strength at elevated temperatures, preventing deformation or failure.

- Resistance to oxidation in high-vacuum conditions, ensuring long-lasting performance.

These properties ensure durability, performance, and reliability in high-stress, high-temperature environments.

Product Details

Applications

Tungsten Brackets are primarily used in the vacuum furnace industry, where they play a key role in holding components or fixtures within the furnace chamber. Some specific applications include:

- Heat treatment of metals and alloys.

- Crystal growth processes for semiconductors.

- Sintering of advanced ceramics and powdered metals.

- Brazing and annealing in controlled atmospheres.

Customization

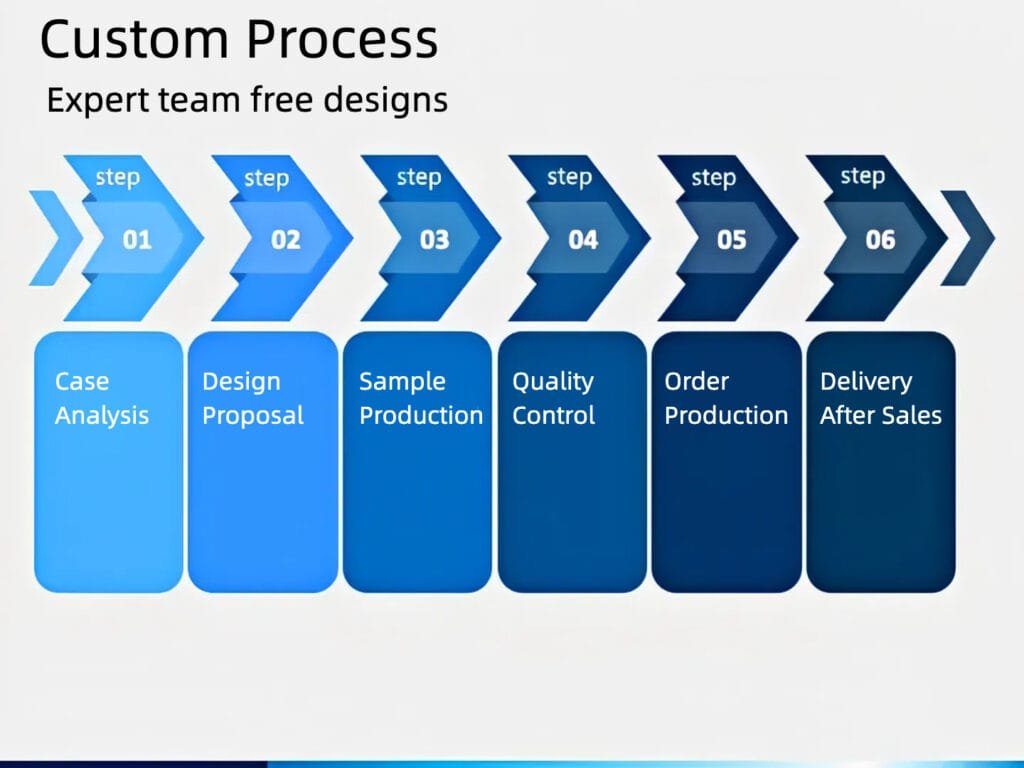

At TFM, we understand that no two vacuum furnace setups are the same. That’s why we offer custom Tungsten Brackets tailored to your specific design requirements, including:

- Precise dimensions and tolerances.

- Specialized coatings to enhance performance.

- Custom geometries to fit unique chamber designs.

Our team works closely with you to deliver the perfect solution, ensuring optimal performance and longevity in your vacuum furnace.

Why TFM

Our Advantages

FACTORY DIRECT SALE

GENUINE MATERIALS

SUPPORT FOR CUSTOM

VARIED SPECIFICATIONS

DETAILS OF THE FINE

INTIMATE AFTER-SALES