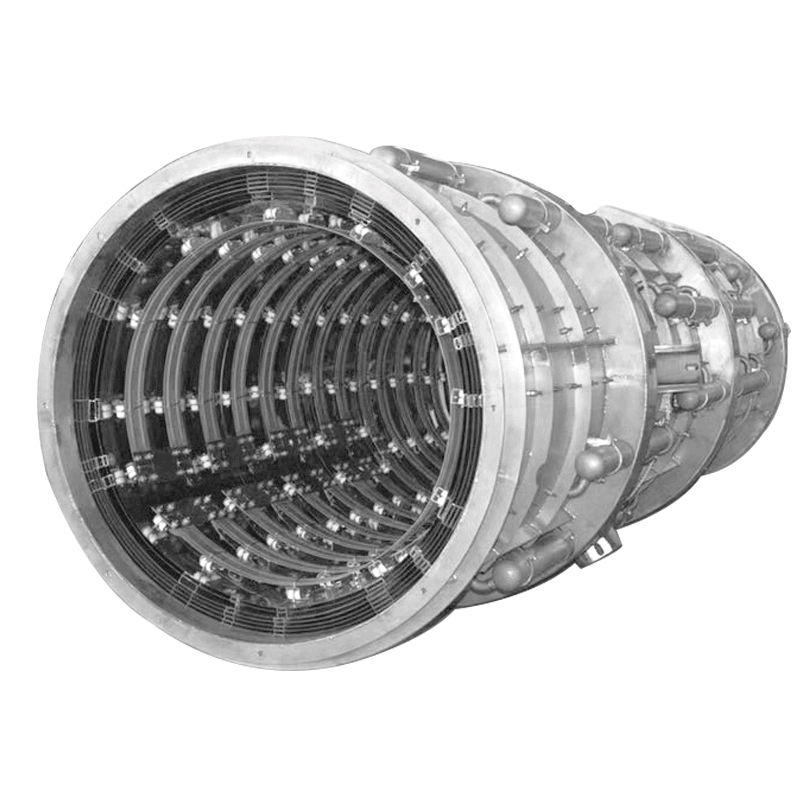

Tungsten Vacuum Furnace Chamber

Tungsten Vacuum Furnace Chamber

Tungsten Vacuum Furnace Chambers are engineered for ultra-high temperature applications where precision and material integrity are critical. With tungsten’s unmatched heat resistance, strength, and low vapor pressure, these chambers provide reliable performance in processes such as sintering, crystal growth, brazing, and advanced material research. Designed to operate in vacuum environments, they prevent oxidation and contamination, ensuring the highest quality results in even the most demanding conditions.

TFM (Thin Film Materials Engineering) is a trusted leader in high-performance vacuum furnace solutions. Committed to quality and innovation, TFM provides expertly crafted tungsten vacuum furnace chambers designed to meet the rigorous demands of modern industry.

Product Specifications

| Specification | Details |

|---|---|

| Brand | TFM |

| Specification | Customized as needed |

| Origin Place | China |

| Material | Tungsten and its alloys |

| Application | Suitable for industries such as vacuum furnaces, rare earths, glass fiber, industrial ceramics, petrochemical, semiconductor manufacturing, aerospace, nuclear technology, and advanced material research, and others. |

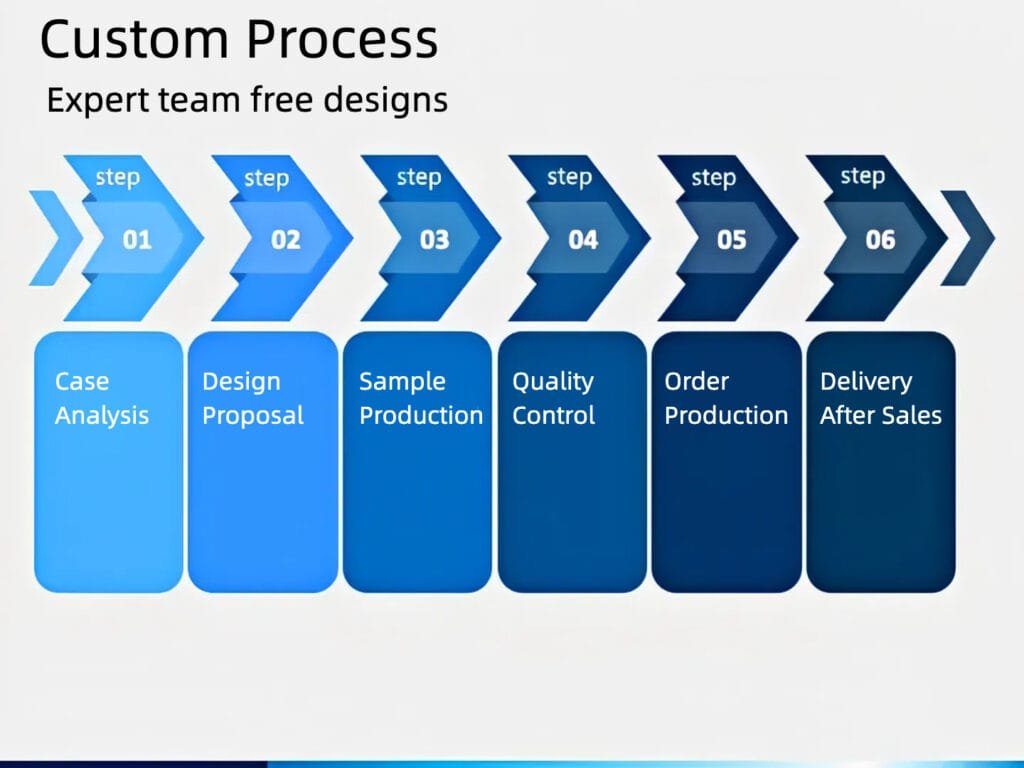

Ordering Process

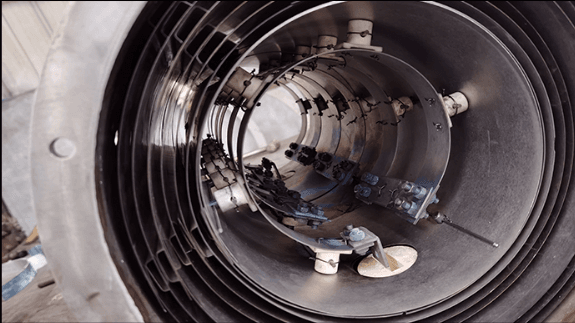

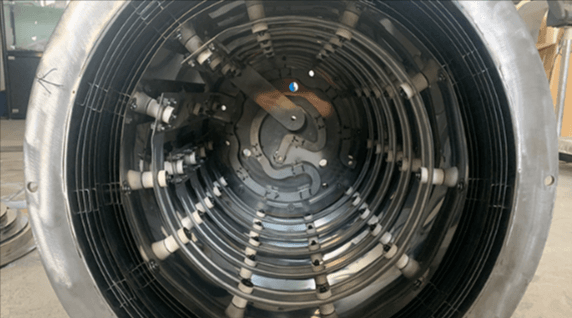

Product Details

The Tungsten Vacuum Furnace Chamber is a highly specialized component designed for ultra-high temperature applications in vacuum environments. Tungsten’s extraordinary properties, such as its highest melting point among all metals and exceptional thermal stability, make it an ideal choice for industries that demand superior heat resistance, strength, and reliability. These chambers are integral to processes where maintaining material purity and structural integrity is essential, even in the most extreme conditions.

Why Tungsten?

Tungsten (W) stands out as the material of choice for high-temperature vacuum furnace chambers due to its remarkable properties:

- Highest Melting Point: Tungsten boasts a melting point of over 3400°C, making it suitable for extreme heat processes.

- Thermal Stability: It retains its mechanical strength and structure at elevated temperatures, ensuring durability and consistent performance.

- Low Vapor Pressure: Tungsten has a low vapor pressure at high temperatures, minimizing the risk of contamination and material evaporation during sensitive processing.

- High Density and Strength: Its exceptional density and mechanical strength provide robustness, ensuring the chamber’s longevity under harsh conditions.

Advantages of Tungsten Vacuum Furnace Chambers

- Unmatched Heat Resistance: Capable of operating at ultra-high temperatures, ensuring stable performance and long service life.

- Precision in Controlled Environments: The vacuum atmosphere prevents oxidation and contamination, ensuring the integrity and purity of processed materials.

- High Strength and Durability: Tungsten’s mechanical properties make the chamber highly resistant to wear and deformation, even in extreme heat.

- Versatility Across Industries: Suitable for diverse applications, including electronics, aerospace, nuclear technology, and advanced material research.

Industries That Rely on Tungsten Vacuum Furnace Chambers

Semiconductor Manufacturing

Tungsten chambers are essential for producing semiconductors and electronic components, where purity and precision are paramount.Aerospace and Defense

These chambers are used to produce high-performance alloys and components critical to aerospace and defense technologies.Nuclear Industry

Tungsten vacuum chambers are utilized in processing and handling nuclear materials, where high heat and vacuum conditions are necessary for safety and efficiency.Advanced Materials and R&D

Research in advanced materials, including high-temperature superconductors and new alloy development, often relies on the capabilities of tungsten vacuum chambers.

Applications

Tungsten vacuum furnace chambers are essential for industries requiring high-temperature and vacuum processing precision. They support a wide range of applications, including:

Crystal Growth Tungsten furnace chambers are widely used in producing high-purity crystals, such as sapphire, silicon, and gallium arsenide, which are critical for the semiconductor and photovoltaic industries. The controlled vacuum environment prevents contamination, allowing for the creation of defect-free crystals.

Sintering of Refractory Metals and Ceramics Sintering processes involving tungsten, molybdenum, tantalum, and other refractory metals are best performed in tungsten vacuum furnace chambers. These chambers enable high-temperature sintering without oxidation, ensuring optimal material properties.

Brazing and Heat Treatment In aerospace, automotive, and electronics manufacturing, tungsten vacuum chambers are ideal for brazing and heat treatment. The vacuum environment eliminates the need for flux, ensuring clean, high-strength joints.

Vacuum Annealing Vacuum annealing of metals such as titanium and stainless steel benefits from tungsten furnace chambers, which provide precise temperature control, reduce surface contamination and improve material properties.

Vacuum Melting and Alloy Production Tungsten chambers are ideal for melting and casting high-purity metals and alloys under vacuum conditions. This process is crucial in producing advanced materials used in the aerospace, medical, and defense industries.

Nuclear Fuel Processing Tungsten vacuum furnace chambers are used to fabricate nuclear fuel pellets, where the material’s purity and integrity are critical for safe and efficient reactor performance.

High-Temperature Coating and Deposition Tungsten vacuum chambers are employed in physical vapor deposition (PVD) and chemical vapor deposition (CVD) processes, which apply high-performance coatings to tools, electronic components, and optical materials.

Graphitization These chambers are ideal for graphitizing carbon-based materials, where high temperatures are needed to convert carbon into graphite, which is essential for the production of electrodes and other advanced materials.

Why Us

Our Advantages

FACTORY DIRECT SALE

GENUINE MATERIALS

SUPPORT FOR CUSTOM

VARIED SPECIFICATIONS

DETAILS OF THE FINE

INTIMATE AFTER-SALES