Zinc Telluride Powder (ZnTe) is a pivotal material in modern material science, bridging the gap between optoelectronics, infrared technologies, thermoelectric devices, and photovoltaic systems. Its unique combination of electrical, optical, and thermal properties makes it a highly sought-after compound in a range of advanced technologies. As industries push the boundaries of miniaturization, efficiency, and integration, Zinc Telluride Powder has emerged as a critical component in both research and commercial sectors.

In this comprehensive article, we’ll explore the material characteristics, production processes, key applications, deposition techniques, and emerging research trends of Zinc Telluride Powder. By the end, you’ll understand why this compound continues to gain momentum across multiple industries.

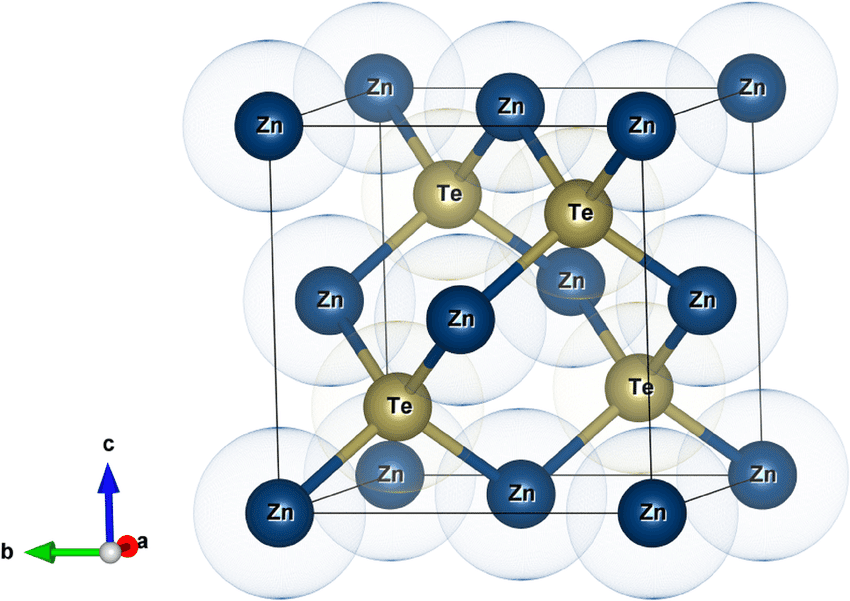

1. Understanding Zinc Telluride Powder: Composition and Crystal Structure

Zinc Telluride (ZnTe) is a II-VI compound semiconductor material, combining zinc (Zn) from group II and tellurium (Te) from group VI in the periodic table. It naturally crystallizes in a zinc blende (cubic) crystal structure, although under certain conditions, it can also form a hexagonal wurtzite structure.

Key Physical Properties of Zinc Telluride Powder:

- Molecular Weight: 193.99 g/mol

- Band Gap: Approximately 2.26 eV (direct) at room temperature

- Crystal Structure: Cubic (zinc blende)

- Density: 6.34 g/cm³

- Melting Point: ~1238°C

- Thermal Conductivity: Low (~10 W/m·K), important for thermoelectric behavior

These features make Zinc Telluride Powder highly compatible for use in infrared optics, thin-film semiconductors, and thermoelectric devices.

2. Synthesis Methods: Producing High-Purity Zinc Telluride Powder

The performance of ZnTe-based materials in advanced applications is strongly tied to the purity and particle size distribution of the powder. To ensure consistent quality, manufacturers employ several synthesis methods:

a. Solid-State Reaction

A direct method involves heating elemental zinc and tellurium under an inert atmosphere:

Zn (s) + Te (s) → ZnTe (s)

This reaction is typically performed in a vacuum or argon-filled quartz ampoule. The resulting ingot is then ground into a fine powder.

b. Chemical Vapor Transport (CVT)

To obtain ultra-high purity ZnTe, a chemical transport agent (e.g., iodine or bromine) is used to sublime the material at high temperature, purify it in vapor phase, and recrystallize it. The final solid can be milled into micron or nano-scale powders.

c. Solvothermal & Hydrothermal Synthesis

For nanostructured powders, solvothermal methods are popular. Zinc salts and tellurium precursors are reacted under high temperature and pressure in the presence of a surfactant, resulting in ZnTe nanoparticles with narrow size distribution.

These methods enable customization of grain size, morphology, and surface characteristics — key factors in tailoring the powder for specific applications like infrared coatings, thermoelectric materials, and photovoltaic cells.

3. Optical and Electronic Properties

Zinc Telluride Powder is particularly prized for its wide band gap and transparency in the infrared (IR) spectrum. Its electronic and optical characteristics position it between cadmium telluride (CdTe) and zinc selenide (ZnSe), offering advantages such as lower toxicity compared to Cd-based compounds.

a. Wide Bandgap Semiconductor

With a direct band gap of ~2.26 eV, ZnTe is suitable for blue to green light emission. This property also makes it an ideal p-type semiconductor in heterojunction solar cells, often paired with materials like CdS, ZnO, or GaAs.

b. Infrared Transparency

ZnTe exhibits low absorption in the near-IR range (2–12 µm), making it excellent for infrared window materials, optical coatings, and laser systems. It can also be doped with transition metals (e.g., Cr, Fe) for active optical components.

c. Thermoelectric Properties

Due to its relatively low thermal conductivity and modifiable Seebeck coefficient, ZnTe powder shows promise in thermoelectric generators (TEGs) and Peltier cooling modules.

4. Applications of Zinc Telluride Powder Across Industries

The versatility of Zinc Telluride Powder is reflected in its use across multiple high-tech domains. Let’s explore some of the most impactful applications.

a. Infrared Optics and Coatings

ZnTe is frequently used to produce infrared lenses, beam splitters, windows, and prisms for thermal imaging systems and spectroscopy. Its powder form enables thermal spraying or hot pressing to fabricate IR-transparent ceramics.

b. Thin-Film Photovoltaics

Zinc Telluride serves as an absorber or buffer layer in CdTe-based solar cells, contributing to junction formation and overall efficiency. ZnTe can also be alloyed with selenium to create ZnTeSe, improving solar spectrum absorption.

c. Thermoelectric Devices

Researchers are exploring ZnTe for solid-state cooling and waste heat recovery due to its potential as an eco-friendly thermoelectric material. Doping and nanostructuring are used to enhance its ZT figure of merit.

d. Optoelectronic Devices

ZnTe-based compounds are being tested in blue and green LEDs, photodetectors, and nonlinear optical devices. Their compatibility with wide-bandgap heterojunctions expands opportunities in high-frequency electronics.

e. Sputtering and Evaporation Targets

In thin film deposition, Zinc Telluride Powder is pressed or bonded into sputtering targets. These are used in vacuum chambers to deposit uniform ZnTe coatings on glass, silicon, or sapphire substrates.

5. Zinc Telluride in Thin Film Deposition

One of the most promising uses of Zinc Telluride Powder lies in thin film technologies, especially for photonic and optoelectronic devices.

a. Sputtering

ZnTe targets made from the powder are used in RF or DC magnetron sputtering to create films with excellent crystalline quality and stoichiometry. Parameters like argon pressure, substrate temperature, and deposition rate are carefully optimized.

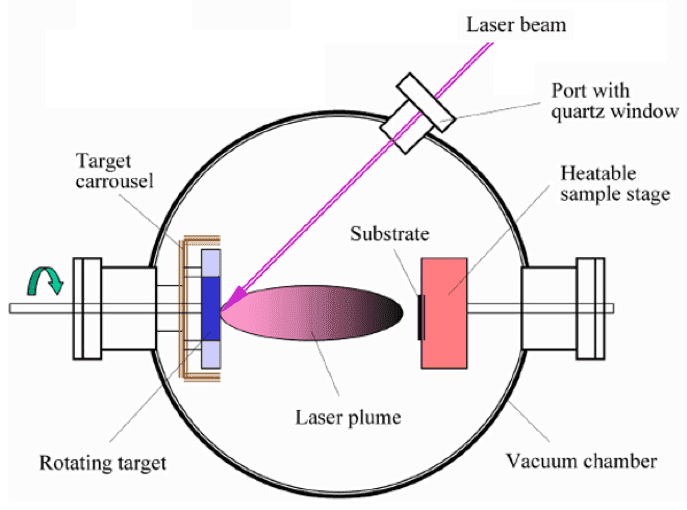

b. Pulsed Laser Deposition (PLD)

PLD offers high control over film thickness and stoichiometry. ZnTe powder is sintered into a target, which is then ablated by a high-energy laser in vacuum or inert gas atmosphere to deposit on a heated substrate.

c. Thermal and E-Beam Evaporation

Zinc Telluride’s thermal stability enables it to be used in thermal evaporation or electron-beam evaporation setups for high-uniformity films on optical devices.

6. Emerging Research and Future Directions

Research on Zinc Telluride Powder is growing rapidly, driven by the quest for eco-friendly, non-toxic, and abundant alternatives to traditional semiconductors.

a. Nanostructured ZnTe

Nanoparticles and quantum dots of ZnTe are showing promising results in bioimaging, LEDs, and photocatalysis due to their tunable bandgap and high surface area.

b. ZnTe Alloys and Heterostructures

By alloying with Se, S, or Mg, scientists are engineering bandgap-tunable materials for custom optoelectronic applications. ZnTe/CdS and ZnTe/ZnO junctions are particularly explored in solar photovoltaics.

c. Flexible Electronics

ZnTe powder is being developed for printed electronics and flexible devices. Inkjet or aerosol jet printing using ZnTe nanoparticle inks opens the door to cost-effective production of wearable sensors and displays.

d. Green Manufacturing

New routes like sol-gel synthesis, microwave-assisted processing, and mechanochemical methods are enabling low-energy, scalable production of ZnTe powders with minimal environmental impact.

7. Handling and Storage Guidelines

Zinc Telluride Powder is generally stable in air but can degrade under humid or acidic conditions.

- Storage: Should be kept in a dry, sealed container, ideally under inert gas.

- Handling: Use gloves and a fume hood to avoid inhalation or direct contact.

- Disposal: Must follow local regulations for semiconductor waste or tellurium compounds.

Proper handling ensures longevity and performance consistency, especially when using ZnTe in cleanroom environments or high-vacuum systems.

8. Commercial Availability and Forms

Zinc Telluride Powder is available from various specialty material suppliers. Common specifications include:

- Purity Levels: 99.9%, 99.99%, and 99.999% (for optoelectronic use)

- Particle Sizes: 1–10 µm (standard); <100 nm (nanopowder)

- Packaging: In sealed bottles, often with inert gas or desiccant

High-purity ZnTe powder is often used to fabricate custom sputtering targets, infrared ceramics, or compound crystals depending on the end application.

Conclusion: Why Zinc Telluride Powder Matters

Zinc Telluride Powder stands at the intersection of multiple technological revolutions — from clean energy to advanced optics and quantum devices. Its tunable properties, compatibility with thin-film technologies, and growing eco-friendliness make it a material of the future.

Whether you’re designing next-generation solar cells, IR sensors, or thermoelectric modules, Zinc Telluride Powder offers a flexible, high-performance material base. With ongoing advancements in synthesis, deposition, and nanostructuring, its potential is only beginning to unfold.

Hot FAQs About Zinc Telluride Powder

- What is Zinc Telluride Powder used for?

It’s used in infrared optics, thin film semiconductors, thermoelectric devices, and laser systems. - Is ZnTe a direct bandgap semiconductor?

Yes, with a bandgap of approximately 2.26 eV, it’s ideal for optoelectronic applications. - Can Zinc Telluride be used in solar cells?

Absolutely. It often serves as a p-type layer or buffer in CdTe and other thin-film solar technologies. - What are the benefits of using ZnTe powder in thermoelectric devices?

Its low thermal conductivity and modifiable electronic properties make it suitable for energy conversion. - How do you deposit ZnTe thin films?

Common methods include sputtering, PLD, thermal evaporation, and e-beam deposition.