Introduction: Understanding Crucibles and Their Importance

A crucible is a container designed to withstand extreme temperatures and hold molten materials, typically metals or chemicals, during high-temperature processing. Crucibles are essential in various industries, from metalworking and casting to laboratories and research applications. They must be made from materials that can resist thermal stress, chemical corrosion, and mechanical wear, ensuring they perform efficiently and last long under harsh conditions.

The selection of the right crucible material depends on factors like the temperature of the material being melted, the chemical properties of the material, and the desired mechanical strength. In this article, we will explore five of the most commonly used materials for crucibles, examining their advantages and ideal applications.

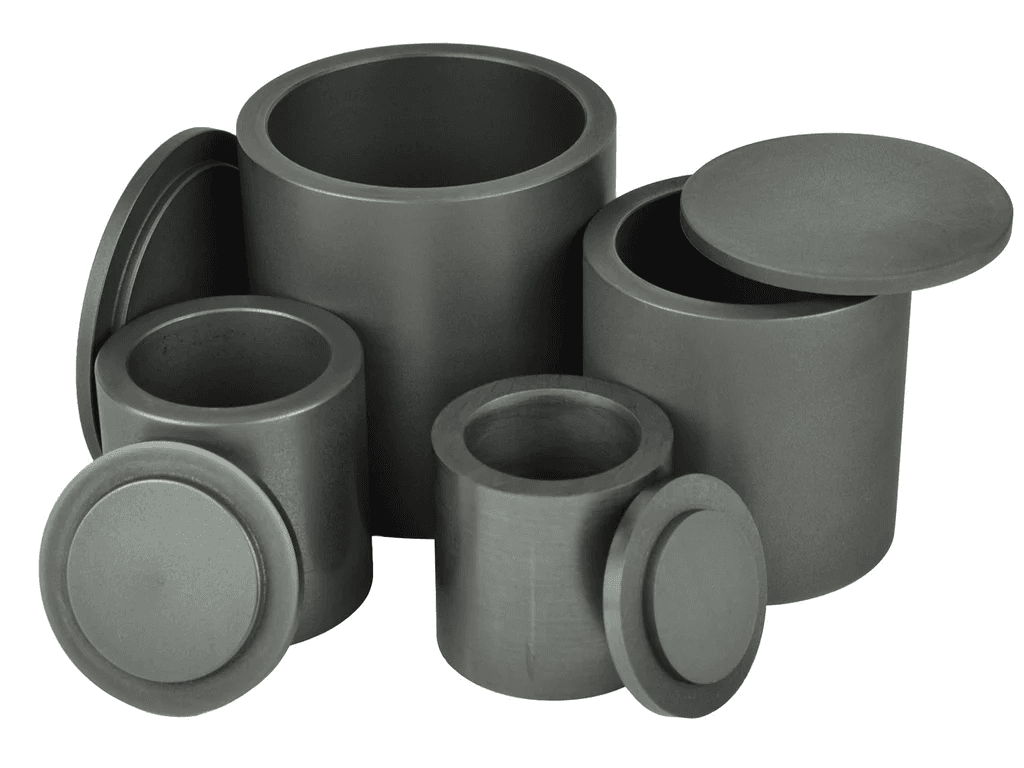

1. Graphite Crucibles

Properties and Characteristics

Graphite is one of the most popular crucible materials, known for its high thermal conductivity, ability to withstand extreme temperatures, and resistance to thermal shock. It can handle temperatures up to 3,000°C, which makes it ideal for melting metals like gold, silver, and copper, as well as non-ferrous alloys. Graphite crucibles are often used in the casting industry, particularly in the production of jewelry and coins.

Benefits

- High Thermal Conductivity: Graphite heats up quickly and efficiently, saving time in many industrial applications.

- Thermal Shock Resistance: Graphite can withstand rapid temperature changes without cracking.

- Cost-Effective: Compared to other high-temperature materials, graphite crucibles are relatively affordable.

Applications

- Casting and Metalworking: Graphite crucibles are commonly used for melting non-ferrous metals and alloys due to their cost-effectiveness and high-temperature resistance.

- Laboratory Uses: They are also utilized in laboratories for high-temperature experiments involving chemical reactions or metals.

Limitations

While graphite is resistant to heat, it is relatively soft compared to other materials and may degrade over time, particularly if exposed to certain chemicals like oxygen at very high temperatures.

2. Platinum Crucibles

Properties and Characteristics

Platinum is one of the most chemically stable and high-performance materials used for crucibles. It can withstand high temperatures (up to 1,750°C) and is resistant to oxidation and corrosion, making it an ideal choice for applications involving highly reactive or pure substances. Platinum is widely used in laboratories, especially in chemical analyses and high-purity melting.

Benefits

- Chemical Resistance: Platinum crucibles are resistant to corrosion from acids, bases, and other corrosive materials.

- Purity: Platinum does not contaminate the materials it holds, making it ideal for precise and sensitive applications.

- Long Lifespan: With proper care, platinum crucibles can last for a long time without degrading, even under extreme conditions.

Applications

- Chemical and Pharmaceutical Industry: Platinum crucibles are essential in industries that require high purity, such as in the production of pharmaceuticals or in chemical research.

- High-Purity Metallurgy: In the production of high-purity metals, platinum’s resistance to contamination is invaluable.

Limitations

The main drawback of platinum crucibles is their cost, as platinum is an expensive metal. However, for high-precision work or when purity is a priority, the benefits often outweigh the expense.

3. Ceramic (Alumina) Crucibles

Properties and Characteristics

Alumina (Al₂O₃) ceramic crucibles are some of the most commonly used crucibles due to their high mechanical strength, thermal stability, and resistance to wear and corrosion. Alumina crucibles can withstand temperatures up to 2,000°C and offer excellent resistance to both acidic and basic environments.

Benefits

- High Mechanical Strength: Ceramic crucibles are robust and can endure mechanical stresses and wear.

- Thermal Shock Resistance: Alumina has good thermal shock resistance, making it suitable for rapid heating and cooling cycles.

- Chemical Resistance: Alumina is resistant to most acids and alkalis, making it an excellent choice for aggressive chemical environments.

Applications

- Metallurgy: Alumina crucibles are widely used in the casting and processing of metals, particularly in applications involving molten steel, aluminum, or other metals.

- Laboratory Applications: They are also used in labs for experiments requiring high temperatures and the handling of reactive chemicals.

Limitations

Ceramic crucibles, while strong, are brittle and may crack under mechanical impact or rapid temperature fluctuations. They can also be porous if not manufactured correctly, which may limit their applications.

4. Silicon Carbide (SiC) Crucibles

Properties and Characteristics

Silicon carbide crucibles are known for their exceptional mechanical strength, thermal shock resistance, and ability to withstand very high temperatures. They can handle temperatures up to 1,800°C and are resistant to wear, making them ideal for industrial applications where durability is critical.

Benefits

- Mechanical Strength: Silicon carbide crucibles are incredibly strong and durable, capable of handling heavy loads without breaking.

- Thermal Shock Resistance: They can withstand extreme and rapid changes in temperature, which makes them suitable for high-efficiency processing.

- High Heat Resistance: Silicon carbide maintains its integrity at very high temperatures, making it ideal for molten metal processing.

Applications

- Foundries and Casting: SiC crucibles are widely used in foundries for casting metals like steel, copper, and brass.

- Laboratory and Research: They are used in applications where both high temperature and resistance to abrasion are necessary.

Limitations

While silicon carbide is extremely durable, it can be prone to oxidation at higher temperatures if exposed to oxygen, making it unsuitable for certain oxidative environments.

5. Tungsten Crucibles

Properties and Characteristics

Tungsten is one of the most heat-resistant metals, with a melting point of 3,422°C. Tungsten crucibles are ideal for melting and processing materials at extreme temperatures. They have excellent mechanical strength and are dense, which helps in withstanding thermal expansion and contraction.

Benefits

- Highest Temperature Resistance: Tungsten crucibles can withstand the highest temperatures of any material, making them perfect for specialized high-temperature applications.

- Mechanical Strength: Tungsten is one of the strongest metals, offering superior resistance to deformation under high stress.

- Durability: Tungsten crucibles are long-lasting and can survive under conditions that would destroy other crucible materials.

Applications

- High-Temperature Metallurgy: Tungsten crucibles are often used for melting metals with extremely high melting points, such as tungsten, titanium, and tantalum.

- Scientific Research: Due to their high-temperature capabilities, tungsten crucibles are used in research environments where high temperatures are required.

Limitations

Tungsten is brittle at room temperature and can be difficult to work with, requiring specialized equipment for shaping and forming. It is also relatively expensive compared to other crucible materials.

Conclusion: Choosing the Best Crucible Material for Your Needs

Selecting the right crucible material depends on your specific application. Each material offers unique advantages in terms of temperature resistance, mechanical strength, chemical resistance, and cost. Graphite is ideal for high thermal conductivity and cost-effective casting. Platinum is perfect for high-purity applications but comes at a premium price. Ceramic (alumina) is robust and resistant to most chemicals but is prone to brittleness. Silicon carbide offers exceptional strength and thermal shock resistance, while tungsten stands out for extreme high-temperature applications.

Understanding the specific demands of your process—whether it’s metalworking, chemical processing, or scientific experimentation—will guide your choice. With careful selection, you can ensure that your crucible delivers reliable performance, safety, and cost-effectiveness for your high-temperature applications.