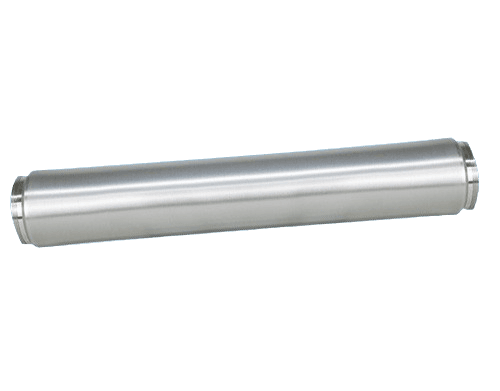

Chromium Cr Rotary Sputtering Target

TFM offers high-quality Chromium Cr rotary sputtering targets, designed for thin-film deposition in a variety of advanced applications, including semiconductors, coatings, and electronics. Chromium Cr targets are known for their exceptional hardness, high wear resistance, and corrosion resistance, making them ideal for producing thin films that require superior durability and reliability in harsh environments.

The rotary sputtering target design ensures efficient, uniform deposition of Chromium Cr films, which are commonly used in hard coatings, optical coatings, and magnetic thin films. Chromium Cr films provide high adhesion strength, making them ideal for protective coatings on materials exposed to extreme temperatures and abrasion. Chromium oxide (Cr₂O₃) films are also widely used in decorative coatings, where their aesthetic appeal and excellent resistance to corrosion are highly valued.

Chromium Cr films are frequently used for tribological coatings to enhance the wear resistance of components such as cutting tools, engine parts, and molds. Additionally, Chromium nitride (CrN) films, created from Chromium targets, are widely employed in hard coatings for tooling and machinery, offering enhanced durability and high-temperature performance. Chromium-based films also play a crucial role in magnetic storage devices and thin-film transistors due to their electrical properties.

TFM provides customized Chromium Cr rotary sputtering targets, ensuring precise control over material composition and purity to meet the specific requirements of high-performance applications. These targets deliver consistent and reliable results for thin-film deposition in industries such as electronics, automotive, aerospace, and medical devices.

Our Chromium Cr rotary sputtering targets are manufactured to the highest standards, offering superior material quality and consistent sputtering performance. With low impurity levels, high density, and optimized sputtering characteristics, TFM’s Chromium Cr targets are ideal for producing high-quality thin films for next-generation technologies.

Specifications

| Materials | Chromium Rotary Sputtering Target |

|---|---|

| Symbol | Cr |

| Purity | 99.5% – 99.95% |

| Theoretical Density (g/cc) | 7.2 |

| Melting Point (°C) | 1,857 |

| Production Method | Spraying Type, Monolithic Type (HIP) |

| Size | As per customer’s drawings |

| Relative Density | >= 95% |

| Grain Sizes | < 100 µm |

| Oxygen Content (ppm) | 5000 (Spraying Type), 800-1500 (HIP) |

| Film Coating Uniformity | High uniformity & density |

| Film Coating Current Density | Not suitable for prolonged high current operation |

| High Power Stability | Stable under high power and extended operation |

Applications

- Thin Film Photovoltaic Solar Industry

- Flat Panel Display Industry

- Construction / Automotive Glass Industry

- Decorative / Functional Coating Industry

Reviews

There are no reviews yet.