Spherical Cobalt-Based Powder (CoCrW): A Premier Solution for Advanced 3D Printing Applications

In the fast-paced realm of additive manufacturing, the demand for high-performance materials continues to escalate. One such standout material is the Spherical Cobalt-Based Powder (CoCrW), a meticulously engineered alloy designed for superior performance in high-stress, high-temperature, and biocompatible applications. This article explores the intricacies of this CoCrW powder, examining its composition, properties, and broad spectrum of applications, while optimizing for popular Google search terms such as “CoCrW powder for 3D printing,” “spherical cobalt alloy powder,” and “high-temperature metal powder.”

1. Introduction to Cobalt-Based Alloys in Additive Manufacturing

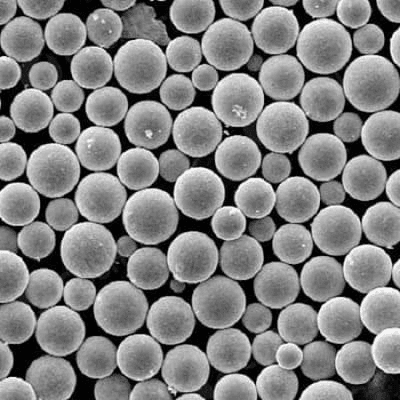

Cobalt-chromium-tungsten (CoCrW) alloys have long been prized for their exceptional wear resistance, strength, and corrosion resistance. These characteristics make them particularly valuable in industries where performance and reliability are paramount. With the advent of metal 3D printing, or additive manufacturing, the use of cobalt-based powders has expanded significantly. This spherical CoCrW powder stands at the forefront of this evolution, thanks to its spherical morphology and tightly controlled particle size distribution.

2. Overview of Spherical Cobalt-Based Powder

This CoCrW powder is characterized by its high purity (99.9%), spherical particle shape, and precise sieved particle size range of 15 to 33 microns. These attributes are critical for ensuring uniform flowability, high packing density, and consistent melting behavior during printing processes.

Key Features:

- Composition: Primarily Cobalt (Co), Chromium (Cr), and Tungsten (W)

- Purity: 99.9%

- Particle Size Distribution: 15–33µm (sieved)

- Shape: Spherical

- Manufacturing Method: Gas atomization

3. Advantages of Spherical Morphology in Metal Powders

Spherical powders are essential for high-precision additive manufacturing. The spherical shape of this CoCrW powder enhances:

- Powder flowability, reducing clogging in recoaters

- Uniform powder bed density, crucial for achieving high-quality layers

- Consistent melt pool dynamics, which improves microstructural integrity

- Reduced porosity in printed parts, leading to higher mechanical strength

These advantages align perfectly with the requirements of laser powder bed fusion (LPBF), direct metal laser sintering (DMLS), and electron beam melting (EBM) systems.

4. Mechanical and Chemical Properties

CoCrW alloys offer a unique combination of hardness, strength, and resistance to corrosion and oxidation at elevated temperatures. These properties make this powder an excellent candidate for parts exposed to harsh environments.

Mechanical Properties (typical of printed parts):

- Ultimate Tensile Strength: >1000 MPa

- Yield Strength: >800 MPa

- Elongation at Break: ~10–15%

- Hardness: 35–45 HRC

Chemical Resistance:

- Exceptional resistance to acids, bodily fluids, and oxidizing environments

- Low magnetic permeability (useful in medical and electronic applications)

5. Applications in Advanced Industries

5.1 Medical and Dental Implants

Due to its excellent biocompatibility and resistance to bodily fluids, this CoCrW powder is widely used in the fabrication of:

- Dental crowns and bridges

- Hip and knee implants

- Spinal fusion devices

The non-reactive nature of the alloy ensures long-term stability and safety in human body environments. It meets stringent standards required by the medical industry, including ASTM F75 for surgical implants.

5.2 Aerospace Components

In aerospace, materials must endure extreme mechanical stress and thermal loads. This powder’s high-temperature strength and oxidation resistance make it ideal for:

- Turbine blades and vanes

- Combustor liners

- Thermal shielding components

The ability to 3D print complex geometries with this powder streamlines the production of optimized, lightweight aerospace parts.

5.3 Automotive and Motorsports

High-performance automotive applications, particularly in motorsports, benefit from this powder’s wear resistance and mechanical stability. Common uses include:

- Exhaust valves

- Turbocharger parts

- High-load bushings

5.4 Industrial Tooling and Wear Parts

This CoCrW powder is also an ideal material for:

- Cutting tools

- Injection mold inserts

- Bearings and valve seats

Its wear resistance dramatically extends the service life of components subjected to abrasive conditions.

6. Processing and Handling Considerations

6.1 3D Printing Techniques

This powder is compatible with several additive manufacturing technologies:

- Laser Powder Bed Fusion (LPBF): Provides excellent resolution and mechanical strength.

- Electron Beam Melting (EBM): Ideal for large parts requiring deep penetration.

- Binder Jetting: Effective for mass production of smaller parts with post-sintering.

6.2 Post-Processing Options

Post-processing enhances the final properties of components made from this powder:

- Hot Isostatic Pressing (HIP): Reduces porosity and increases density

- Heat Treatment: Improves toughness and fatigue resistance

- Surface Finishing: Polishing, coating, or machining for aesthetic and functional purposes

7. Quality Control and Certifications

This powder undergoes rigorous quality assurance steps:

- Particle size analysis (laser diffraction)

- Flowability testing (Hall flow and spreadability)

- Morphology evaluation (SEM imaging)

- Chemical purity (ICP-OES or GDMS analysis)

It conforms to industry standards such as ISO 5832-4, ASTM F75, and ISO 13485 (for medical device manufacturing).

8. Storage and Safety

To maintain the integrity of this CoCrW powder:

- Store in a dry, inert atmosphere (argon/nitrogen)

- Avoid exposure to moisture or contaminants

- Use PPE during handling to avoid inhalation of fine particles

Proper handling ensures safe usage and consistent performance during printing.

9. Environmental and Economic Impact

Cobalt-based alloys like this one are relatively sustainable when used efficiently in additive manufacturing:

- Reduced waste compared to subtractive methods

- Recyclable powders from unused feedstock

- Optimized inventory due to on-demand production

Though the raw materials are costly, the long-term savings from reduced material waste, increased part longevity, and minimized tooling make this CoCrW powder an economically viable choice.

10. Future Prospects and Innovations

With the growth of 3D printing in regulated sectors, demand for reliable metal powders like this CoCrW variant is rising. Innovations may include:

- Nano-enhanced CoCrW formulations

- Hybrid manufacturing with embedded sensors

- AI-driven process optimization

These advancements will likely broaden the scope of CoCrW applications and improve process efficiency.

Conclusion

Spherical Cobalt-Based Powder (CoCrW) represents a top-tier solution for high-performance 3D printed parts in demanding applications. Its combination of spherical morphology, high purity, and superior mechanical properties ensures its role in shaping the future of additive manufacturing across medical, aerospace, and industrial sectors.

For engineers, designers, and manufacturers seeking a reliable material that meets the challenges of advanced manufacturing, this powder offers both versatility and performance.