1. Introduction: The Economics of Sputtering Target Usage

Sputtering deposition is the backbone of modern thin-film fabrication across industries such as semiconductors, optics, photovoltaics, data storage, and aerospace. At the core of the process are sputtering targets, the consumable materials eroded to deposit functional thin films.

Target design has evolved over decades to meet increasing demands for film quality, deposition throughput, and cost control. Among the most significant factors influencing target performance and economics is its thickness.

- Thin targets are less material-intensive, easier to cool, and faster to fabricate.

- Thick targets provide longer lifetimes, fewer interruptions, and potentially lower downtime costs.

However, the choice between thin and thick sputtering targets is far from straightforward. It involves balancing process efficiency, target utilization rates, capital costs, and film quality stability.

This article explores the performance of thin versus thick sputtering targets, their application scenarios, and the trade-offs between cost and efficiency.

2. Fundamentals of Sputtering Targets

2.1 Role of Targets in Thin-Film Deposition

Sputtering targets are blocks or plates of materials—metals, alloys, or ceramics—placed inside a vacuum chamber. When bombarded with energetic ions, atoms are ejected from the target surface and deposited onto substrates to form thin films.

The target’s geometry, thickness, and bonding directly affect:

- Lifetime before replacement

- Deposition uniformity

- Cooling efficiency

- Process stability

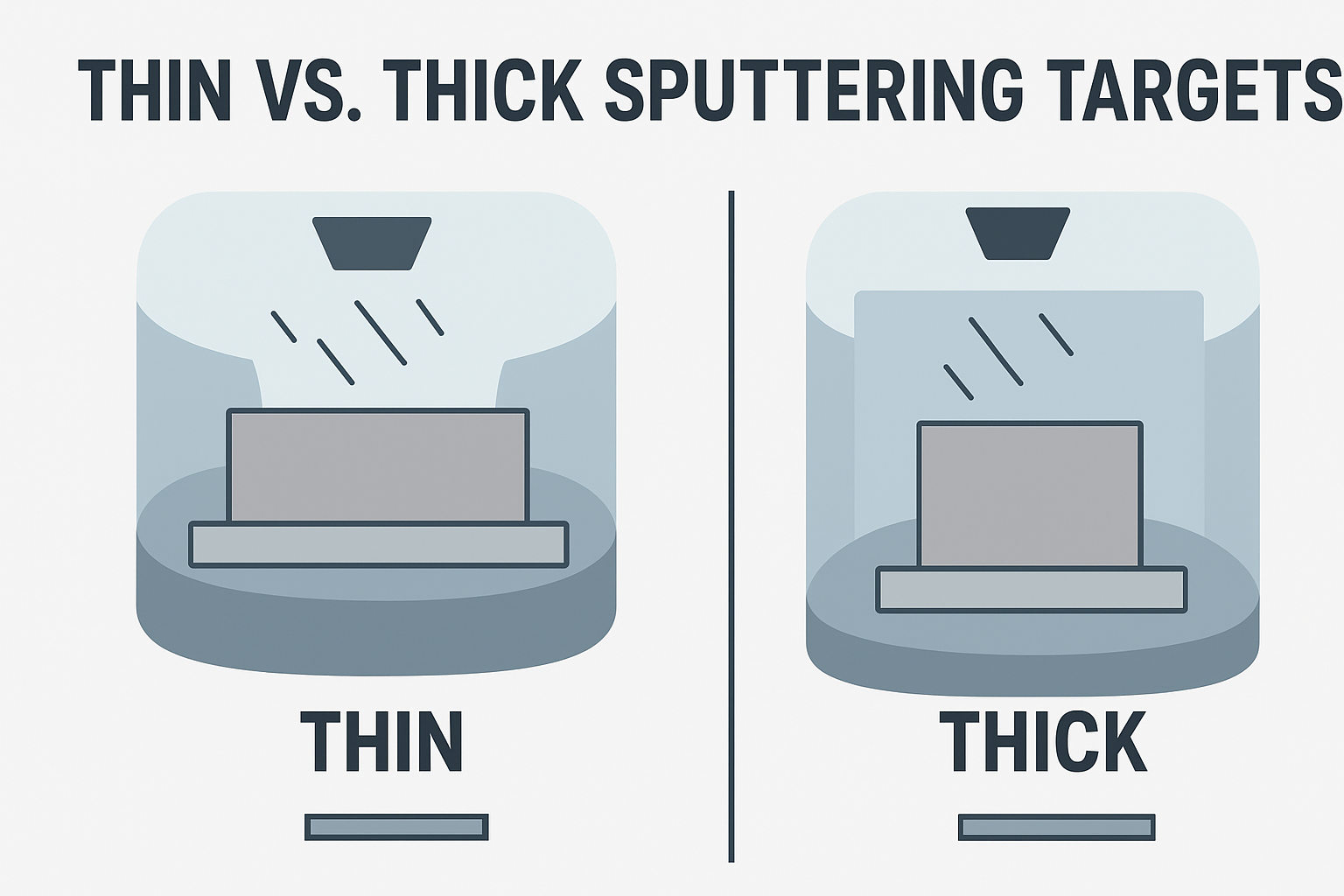

2.2 Target Thickness Categories

- Thin targets: Typically 1–5 mm in thickness, often bonded to a backing plate for mechanical support and cooling.

- Medium targets: 5–10 mm thickness, offering intermediate lifetimes.

- Thick targets: >10 mm thickness, sometimes extending to several centimeters for long campaigns.

3. Lifetime Differences Between Thin and Thick Targets

3.1 Thin Targets

- Lifetime: Shorter, typically requiring replacement after 50–200 hours of operation (depending on erosion rate and plasma conditions).

- Material Utilization: High bonding-to-target ratio may reduce utilization efficiency, often 50–70%.

- Erosion Profiles: Narrow erosion grooves due to magnetron confinement lead to uneven wear.

3.2 Thick Targets

- Lifetime: Extended, often lasting 500–2000 hours, reducing replacement frequency.

- Material Utilization: Potentially higher utilization (>75%) if cooling and bonding are optimized.

- Risk: Thermal stress buildup and cracking can occur due to thicker material mass.

4. Application Scenarios

4.1 When Thin Targets Are Preferred

- Research and Development (R&D): Flexibility and small batch needs make thin targets cost-effective.

- Specialty Materials: Precious or rare elements (e.g., platinum, iridium, ruthenium) where minimizing upfront material investment is critical.

- Frequent Composition Changes: In exploratory thin-film research, short campaigns prevent thick target utilization.

4.2 When Thick Targets Are Preferred

- High-Volume Manufacturing (HVM): Semiconductor fabs, flat-panel displays, and photovoltaics require uninterrupted operation and benefit from fewer changeovers.

- Large-Area Coatings: Architectural glass or solar panel manufacturing demands long campaign runs.

- High-Power Magnetrons: Thick targets withstand prolonged erosion under continuous load.

5. Cost vs. Efficiency: The Trade-Off

5.1 Cost Factors

- Thin Targets:

- Lower material cost upfront.

- Higher downtime cost due to frequent replacement.

- Potentially lower material utilization (more residual waste).

- Thick Targets:

- Higher upfront investment, especially for expensive materials.

- Lower downtime cost (less frequent changeovers).

- Higher utilization efficiency if erosion is uniform.

5.2 Efficiency Factors

- Deposition Stability:

- Thin targets may suffer from changing erosion zones more quickly.

- Thick targets provide consistent deposition rates over longer periods.

- Process Yield:

- Thick targets reduce contamination risk from frequent handling.

- Thin targets are easier to swap without long conditioning periods.

6. Case Studies

6.1 Semiconductor Manufacturing

In EUV mask blank production, molybdenum and silicon targets are used. Thin Si targets are often chosen for flexibility, while thicker Mo targets are used for stable multilayer deposition.

6.2 Architectural Glass Coatings

Large sputter coaters use thick ZnO, ITO, or Ag targets that last for weeks of continuous production. The extended lifetime reduces downtime, critical in continuous glass manufacturing lines.

6.3 Precious Metal Applications

In optical coatings (e.g., ruthenium, iridium), thin targets are favored to minimize locked-in capital and reduce waste of expensive materials.

7. Engineering Challenges

- Thermal Stress: Thick targets are more prone to cracking due to differential thermal expansion.

- Bonding Issues: Thin targets require reliable bonding to avoid delamination during sputtering.

- Cooling Efficiency: Thick targets can trap heat, necessitating advanced cooling systems.

- Erosion Uniformity: Both thin and thick targets require precise magnetron design to maximize utilization.

8. Innovations and Future Outlook

- Segmented Targets: Combining multiple thin segments to mimic thick target lifetimes while controlling stress.

- Advanced Bonding Techniques: Indium bonding, diffusion bonding, and active brazing improve heat transfer.

- Target Utilization Algorithms: AI-driven process control optimizes erosion patterns for both thin and thick targets.

- Hybrid Targets: Medium-thickness designs offering a compromise between lifetime and upfront cost.

9. Conclusion

The debate between thin versus thick sputtering targets reflects the ongoing balance between cost efficiency and operational stability.

- Thin targets excel in R&D, specialty materials, and cost-sensitive rare element applications.

- Thick targets dominate in high-volume manufacturing, large-area coatings, and long campaign processes.

For companies like TFM, the ability to deliver both thin and thick targets with optimized bonding, high purity, and uniform microstructures ensures adaptability to customer needs. Future innovations in target fabrication and utilization strategies will continue to push the boundary of efficiency, enabling sputtering to remain the cornerstone of thin-film technology.