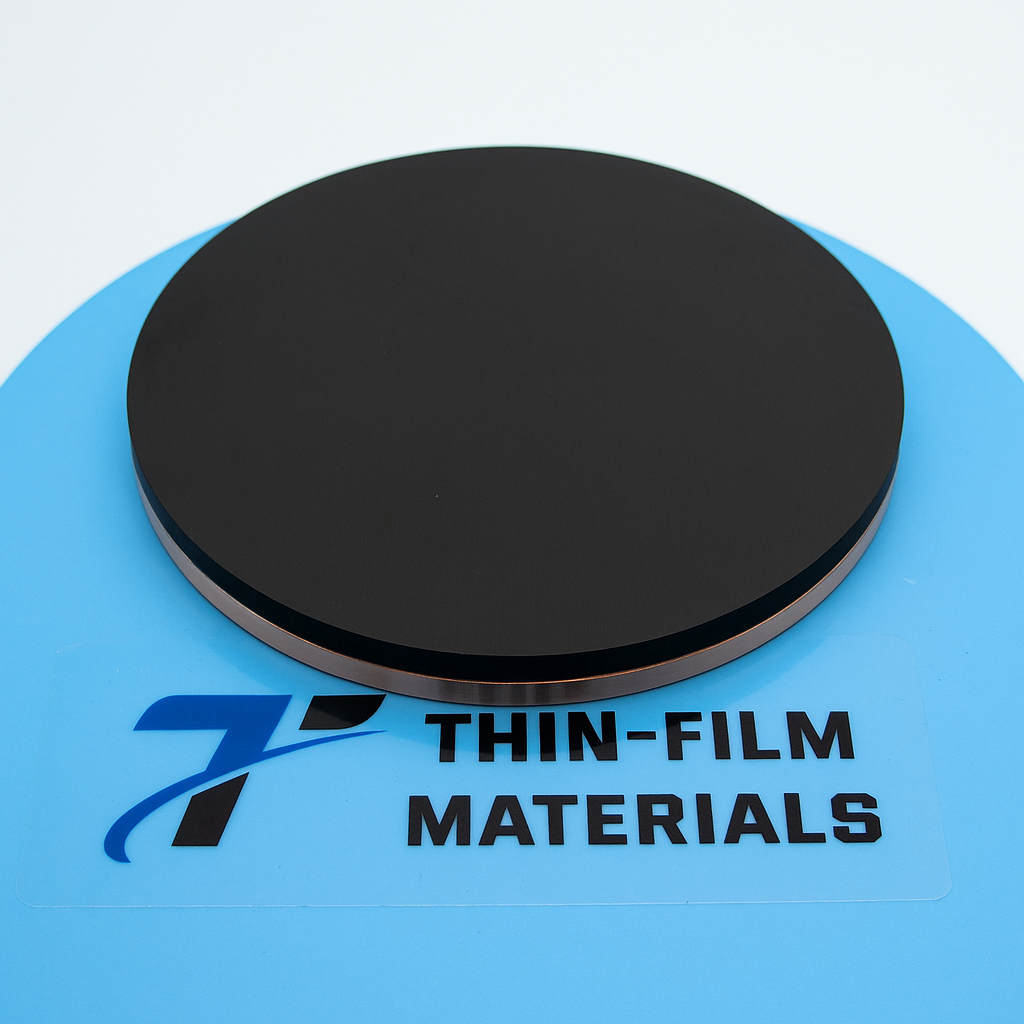

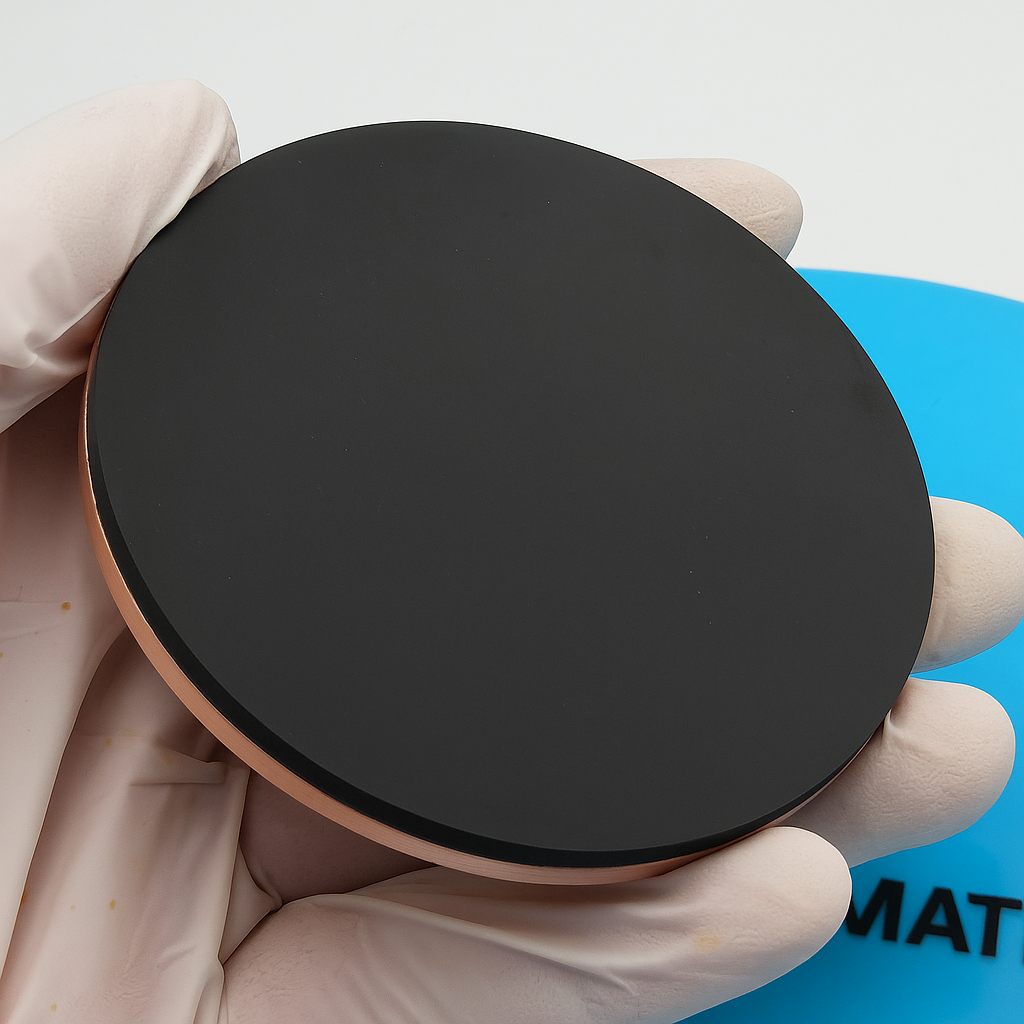

Nickel oxide (NiO) doped with lithium oxide (LiO₂) is becoming one of the most important functional oxide materials in modern thin-film engineering. When manufactured into a NiO–LiO₂ sputtering target, this material enables highly conductive, transparent, and stable p-type oxide films for a wide range of electronic and energy-related applications.

From transparent electronics and smart windows to gas sensors and thin-film batteries, Li-doped NiO sputtering targets offer exceptional performance advantages that pure NiO cannot achieve.

This article provides a comprehensive, keyword-rich overview covering composition, properties, deposition techniques, and real-world applications for NiO doped with LiO₂ sputtering targets.

What Is a NiO Doped with LiO₂ Sputtering Target?

A NiO doped with LiO₂ sputtering target is a ceramic or composite sputter-deposition material made by adding lithium oxide to nickel oxide. Typical Li doping levels range from 1–10 mol%, depending on the electrical and optical performance required.

The target is used in:

- RF magnetron sputtering

- DC sputtering (with proper power control)

- Reactive sputtering systems

During deposition, lithium ions incorporate into the NiO lattice, improving carrier concentration and modifying film properties.

Why Use LiO₂-Doped NiO for Thin Films?

Pure NiO is a stable p-type oxide semiconductor but suffers from high resistivity and limited carrier mobility. Lithium doping solves these limitations.

Key Advantages of Li-Doped NiO Thin Films:

- Higher p-type conductivity

- Lower resistivity

- Improved transparency in the visible range

- Enhanced electrochromic performance

- Better catalytic activity

- Greater film uniformity and density

The combination makes Li-NiO an excellent material for electrochromic devices, TCO structures, sensors, and thin-film batteries.

Doping Mechanism of LiO₂ in NiO

Lithium ions (Li⁺) substitute for nickel in the NiO crystal lattice:

- Li⁺ replaces Ni²⁺

- Charge imbalance occurs

- Ni²⁺ becomes Ni³⁺ to compensate

This oxidation creates additional holes (positive carriers), dramatically improving conductivity.

Resulting material effects:

- Reduced bandgap (depending on doping level)

- Higher hole mobility

- Improved electrical performance

- Modified microstructure and grain size

This mechanism is why LiO₂-doped NiO sputtering targets are widely used for high-performance oxide electronics.

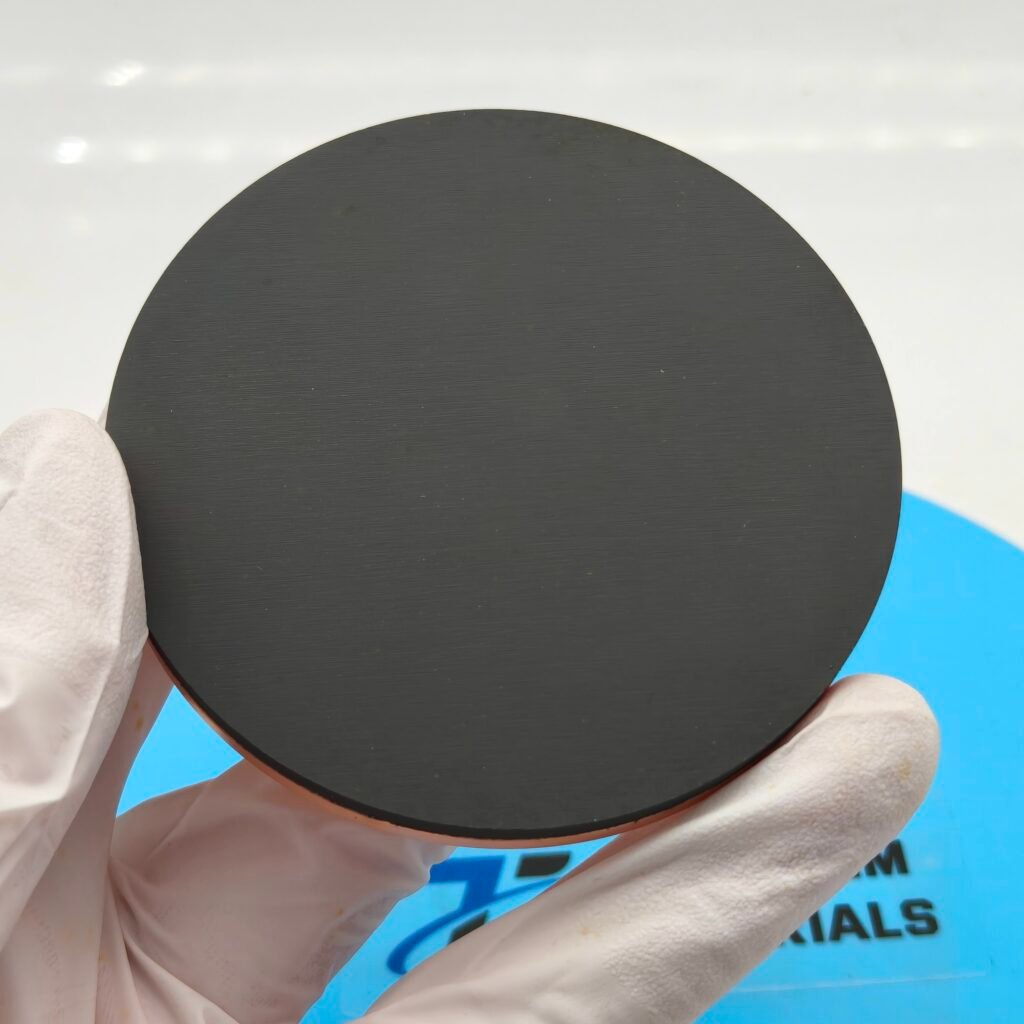

Manufacturing Process of NiO–LiO₂ Sputtering Targets

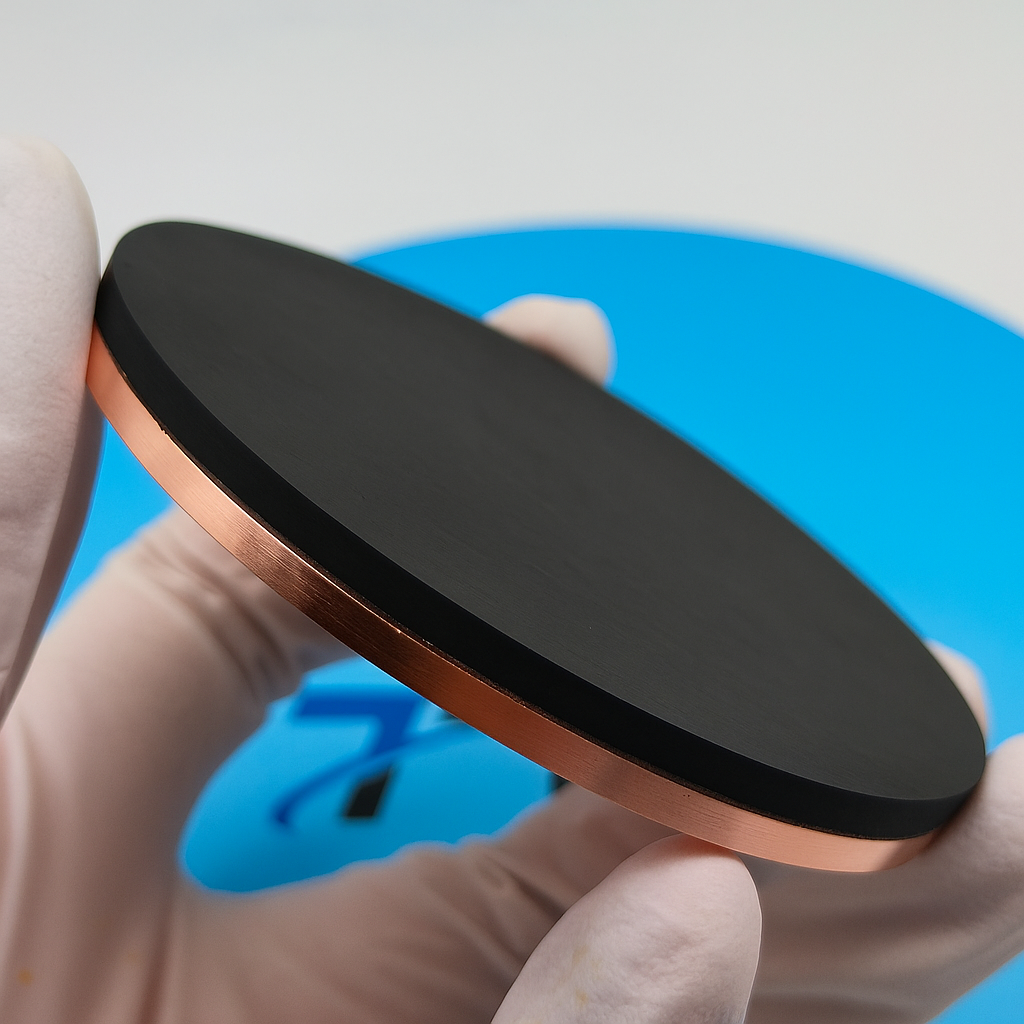

High-quality targets are crucial for stable sputter deposition. Manufacturers typically use:

1. Solid-State Sintering (Conventional Ceramic Processing)

- NiO and LiO₂ powders are weighed and mixed

- Ball milling ensures uniform dopant distribution

- Powders are pressed into molds and pre-sintered

- Final sintering occurs at 1200–1400°C

2. Hot Pressing or HIP (Hot Isostatic Pressing)

Improves density and eliminates microvoids, resulting in:

- Higher target density

- Better deposition uniformity

- Lower particle generation

3. Bonding to Backing Plates

Large-area targets may be:

- Indium bonded

- Elastomer bonded

- Copper/Titanium backing plates

These improve heat transfer and prevent cracking during sputtering.

Sputtering Performance of Li-Doped NiO Targets

Lithium-doped NiO sputtering targets are compatible with:

- RF magnetron sputtering (most common)

- Pulsed DC sputtering

- Reactive sputtering (in O₂/Ar mixes)

Typical Film Properties Achievable:

- Resistivity reduction by several orders of magnitude

- Optical transmittance >75% (depending on thickness)

- Smooth, compact microstructure

- Excellent adhesion on glass, ITO, Si, and sapphire

- High electrochemical stability

This makes Li-NiO films suitable for both research and industrial production.

Applications of NiO Doped with LiO₂ Sputtering Targets

1. Electrochromic Devices & Smart Windows

Li-doped NiO is one of the best p-type electrochromic materials, offering:

- High coloration efficiency

- Faster switching times

- Long cycling durability

Used in:

- Smart glass

- Architectural windows

- Automobiles and building energy systems

2. Transparent Electronics

Li-NiO is a promising p-type transparent conducting oxide (TCO) for:

- Transparent thin-film transistors (TFTs)

- Complementary oxide electronics (p-type NiO with n-type IGZO or ZnO)

3. Gas Sensors

Increased hole concentration improves detection of:

- Hydrogen

- Ethanol

- CO/NO₂

- VOCs

Li-doped NiO sensors show higher sensitivity and lower detection limits.

4. Lithium-Ion Batteries

Li-doped NiO thin films can be used as:

- Anode coatings

- Solid electrolyte interlayer films

- Protective layers for cathode materials

5. Photovoltaics & Photocatalysis

Li-NiO enhances:

- Hole transport in solar cells

- Photocatalytic degradation

- Water-splitting efficiency

6. Resistive Switching & Memristors

Li-NiO thin films exhibit stable:

- Switching voltages

- Filament formation

- Nonlinear conduction

Used in neuromorphic and memory-device research.

Choosing the Right NiO–LiO₂ Sputtering Target

When selecting a Li-doped NiO sputtering target, users should consider:

- Doping percentage (commonly 2%, 5%, 10%)

- Purity level (standard: 99.9% to 99.99%)

- Target density (higher density = better thin-film quality)

- Grain uniformity

- Single-piece or bonded construction

- Backing plate compatibility

High-density targets reduce arcing, increase deposition stability, and improve film uniformity.

Why NiO Doped with LiO₂ Is Becoming Essential

With the global demand for high-performance oxide thin films rising, Li-doped NiO sputtering targets offer a reliable route to:

- More efficient smart windows

- Faster electrochromic devices

- Better transparent p-type layers

- Next-generation sensors and batteries

- Emerging applications in IoT and flexible electronics

Its tunable conductivity, transparency, and chemical stability give it a competitive edge over many traditional p-type materials.