Introduction

Scandium Gallium Iron Oxide Sputtering Targets are advanced complex-oxide materials engineered for next-generation thin film deposition. By combining scandium’s lattice-stabilizing effect, gallium’s electronic modulation capability, and iron’s magnetic functionality, this material system enables precise control over electrical, magnetic, and optical properties. It is widely studied and applied in functional oxide electronics, spintronic research, and advanced optoelectronic devices where compositional accuracy and film uniformity are critical.

Detailed Description

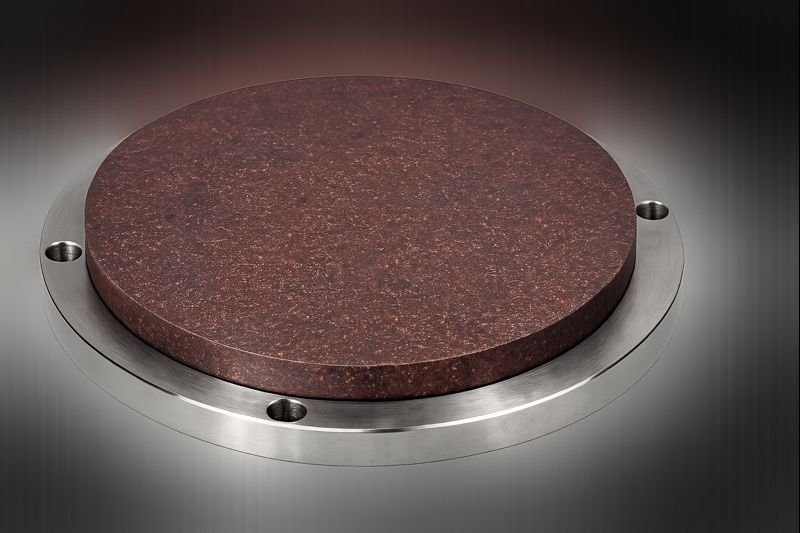

The Scandium Gallium Iron Oxide Sputtering Target is typically manufactured as a dense ceramic target through high-purity powder synthesis, controlled stoichiometric mixing, and hot-pressing or HIP sintering. This process ensures excellent phase uniformity and minimizes porosity, which directly contributes to stable sputtering behavior and consistent film composition.

Scandium plays a key role in stabilizing crystal structures and reducing defect density in deposited films. Gallium contributes to bandgap tuning and carrier transport optimization, while iron introduces magnetic ordering or magneto-optical response depending on deposition conditions and substrate selection. The resulting oxide films can exhibit tailored conductivity, dielectric response, and magnetic anisotropy.

Targets are available in planar or customized geometries, with optional metallic backing plates to improve thermal conductivity and mechanical stability during high-power sputtering. Strict control of impurity levels is maintained to support research-grade and pilot-scale production requirements.

Applications

Scandium Gallium Iron Oxide Sputtering Targets are used across a range of advanced research and industrial thin-film applications, including:

Functional oxide thin films for semiconductor and oxide electronics

Spintronic devices and magnetic oxide research

Magneto-optical coatings and sensors

Transparent or semi-conductive oxide layers

R&D for multiferroic and strongly correlated materials

Advanced academic and industrial materials research programs

Technical Parameters

| Parameter | Typical Value / Range | Importance |

|---|---|---|

| Chemical Composition | Sc–Ga–Fe–O (custom stoichiometry) | Determines electrical & magnetic properties |

| Purity | 99.9% – 99.99% | Reduces defects and contamination |

| Diameter | 25 – 300 mm (custom available) | Compatible with most sputtering systems |

| Thickness | 3 – 6 mm | Influences sputtering stability |

| Density | ≥ 95% of theoretical | Ensures uniform sputter rate |

| Bonding | Copper or Titanium backing | Improves heat dissipation & target life |

| Sputtering Mode | RF sputtering (typical) | Suitable for oxide materials |

Comparison with Related Materials

| Material | Key Advantage | Typical Application |

|---|---|---|

| Scandium Gallium Iron Oxide | Tunable magnetic & electronic behavior | Spintronics, oxide electronics |

| Gallium Iron Oxide | Strong magnetic response | Magneto-optical devices |

| Scandium Oxide | Structural stabilization | Dielectric and optical coatings |

| Iron Oxide | Cost-effective magnetism | Sensors, catalysts |

FAQ

| Question | Answer |

|---|---|

| Can the composition be customized? | Yes. Scandium, gallium, and iron ratios can be adjusted based on application needs. |

| Is the target suitable for RF sputtering? | Yes. RF sputtering is recommended for stable oxide film deposition. |

| Are backing plates available? | Copper or titanium backing plates can be supplied upon request. |

| What research fields commonly use this target? | Semiconductor research, spintronics, functional oxides, and advanced materials R&D. |

| How is the target packaged? | Vacuum-sealed with protective foam in export-grade cartons or wooden crates. |

Packaging

Our Scandium Gallium Iron Oxide Sputtering Targets are carefully labeled and externally tagged for clear identification and quality traceability. Each target is vacuum-sealed and protected against moisture, contamination, and mechanical damage to ensure it arrives in optimal condition for immediate use.

Conclusion

Scandium Gallium Iron Oxide Sputtering Targets offer a versatile platform for depositing high-performance functional oxide films with precisely engineered magnetic and electronic properties. With reliable material quality, flexible customization options, and strict quality control, this target is well-suited for both cutting-edge research and advanced development projects.

For detailed specifications and a quotation, please contact us at sales@thinfilmmaterials.com.

Reviews

There are no reviews yet.