Introduction

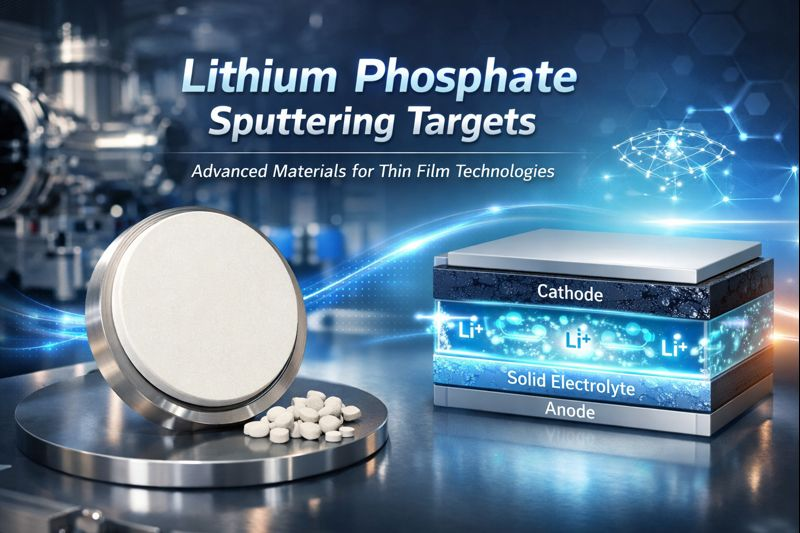

As thin-film technologies continue to evolve toward higher functionality, stability, and integration density, material selection for sputtering targets has become increasingly critical. Among various compound targets, Lithium Phosphate Sputtering Targets occupy a distinctive position due to their unique chemical structure, deposition behavior, and functional relevance in energy-related and electronic applications. Unlike conventional metal or simple oxide targets, lithium phosphate targets combine structural stability with lithium-ion compatibility, making them particularly attractive for solid-state batteries, micro-energy devices, and advanced functional coatings.

This article provides an in-depth analysis of the unique characteristics of lithium phosphate sputtering targets, focusing on their structural nature, sputtering behavior, thin-film properties, and application-level advantages. Rather than offering generic descriptions, the discussion emphasizes why lithium phosphate stands apart from other lithium-based or phosphate-based sputtering materials.

1. Structural Uniqueness at the Material Level

1.1 Stable Phosphate Framework

Lithium phosphate belongs to a class of inorganic compounds built around PO₄ tetrahedral units. These phosphate groups form highly stable covalent P–O bonds, which are among the strongest in oxide chemistry. This structural feature gives lithium phosphate an inherent resistance to thermal decomposition and chemical instability during vacuum processing.

Compared with lithium oxide or lithium-rich mixed oxides, lithium phosphate is far less reactive toward residual moisture or oxygen fluctuations inside the deposition chamber. This stability is not only beneficial for storage and handling but also plays a crucial role during plasma exposure in sputtering processes.

1.2 Lithium Incorporated in a Robust Network

Lithium is a lightweight and highly mobile element, which often causes difficulties in thin-film deposition due to preferential sputtering or re-evaporation. In lithium phosphate, however, lithium ions are embedded within a rigid phosphate network. This structural “anchoring” effect reduces uncontrolled lithium loss during sputtering and contributes to better stoichiometric transfer from target to film.

This intrinsic stabilization of lithium distinguishes lithium phosphate sputtering targets from many other lithium-containing targets, where lithium deficiency in the deposited film is a common challenge.

2. Distinctive Sputtering Behavior

2.1 Improved Stoichiometric Transfer

One of the most notable advantages of lithium phosphate sputtering targets is their relatively stable compositional transfer during deposition. In multi-element sputtering systems, differences in atomic mass and bonding energy often lead to elemental imbalance in the growing film.

Lithium phosphate mitigates this issue through:

- Strong P–O bonding that resists selective sputtering,

- Reduced volatility of lithium when bonded within the phosphate lattice,

- More uniform sputtered species energy distribution under RF plasma.

As a result, lithium phosphate films deposited under optimized conditions often exhibit chemical compositions closer to the target material than films derived from simpler lithium compounds.

2.2 Compatibility with RF Sputtering

Lithium phosphate is typically an insulating or semi-insulating ceramic material, making RF sputtering the preferred deposition method. Under RF excitation, plasma stability is high, target charging is minimized, and arcing risks are significantly reduced.

Compared with some oxide targets that suffer from target poisoning or unstable discharge, lithium phosphate targets generally demonstrate:

- Smooth plasma operation,

- Predictable deposition rates,

- Minimal target surface degradation over extended runs.

This operational reliability is a key practical advantage for research laboratories and pilot-scale production environments.

2.3 Process Window Flexibility

Lithium phosphate sputtering targets show a relatively wide process tolerance with respect to:

- Working gas pressure,

- RF power density,

- Substrate temperature.

This flexibility allows users to tailor film microstructure—from amorphous to partially crystalline—without introducing severe compositional deviations. Such adaptability is particularly valuable during early-stage material screening and device prototyping.

3. Unique Properties of Lithium Phosphate Thin Films

3.1 Chemical and Thermal Stability

Lithium phosphate thin films inherit the chemical resilience of the bulk material. Once deposited, these films exhibit strong resistance to:

- Moisture-induced degradation,

- Oxygen exchange reactions,

- Thermal stress during post-annealing.

This stability makes lithium phosphate films suitable as functional buffer layers or protective interlayers in multilayer thin-film stacks, especially where long-term reliability is essential.

3.2 Lithium-Ion Compatibility

A defining characteristic of lithium phosphate thin films is their intrinsic compatibility with lithium-ion systems. Unlike metallic lithium coatings or reactive lithium oxides, lithium phosphate remains chemically stable when in contact with lithium-containing electrodes.

In practical terms, this means lithium phosphate films can:

- Serve as lithium-ion transport layers,

- Act as diffusion barriers that suppress undesirable interfacial reactions,

- Improve interface stability in solid-state electrochemical devices.

This property is one of the core reasons lithium phosphate sputtering targets are increasingly used in energy-related thin-film research.

3.3 Tunable Electrical Behavior

Depending on deposition conditions and post-treatment, lithium phosphate thin films can exhibit a range of electrical behaviors:

- Highly insulating films for dielectric or passivation layers,

- Ionically conductive films suitable for electrolyte or interface engineering.

This tunability allows lithium phosphate films to function not as a single-purpose material, but as a versatile platform adaptable to different device architectures.

4. Comparison with Other Lithium-Based Sputtering Targets

4.1 Versus Lithium Oxide Targets

Lithium oxide targets are known for their high reactivity and strong tendency to absorb moisture. In contrast, lithium phosphate:

- Is significantly more stable during storage,

- Exhibits lower hygroscopicity,

- Provides better film composition control.

From a process engineering perspective, lithium phosphate targets are easier to manage and deliver more consistent results over repeated deposition cycles.

4.2 Versus Lithium-Transition-Metal Oxide Targets

Lithium transition-metal oxides introduce additional complexity due to variable oxidation states and potential redox reactions during sputtering. Lithium phosphate avoids these issues entirely, as it contains no multivalent metal cations.

This absence of redox-active species results in:

- Reduced plasma-induced chemical fluctuations,

- More predictable film chemistry,

- Lower risk of unintended phase formation.

5. Application-Driven Uniqueness

5.1 Solid-State Battery and Energy Devices

Lithium phosphate sputtering targets are particularly well-suited for solid-state battery research, where thin, uniform, and chemically stable lithium-containing films are required. Lithium phosphate layers are often explored as:

- Solid electrolyte components,

- Interfacial buffer layers between electrodes and electrolytes,

- Protective coatings to enhance cycling stability.

Their compatibility with vacuum deposition techniques enables precise thickness control at the nanometer to micrometer scale, which is critical for micro-battery architectures.

5.2 Microelectronics and Functional Thin Films

Beyond energy storage, lithium phosphate thin films are also relevant in:

- Microelectronic passivation layers,

- Ion-blocking or ion-selective coatings,

- Specialized dielectric or functional oxide systems.

The ability to deposit uniform, pinhole-free films over complex substrates adds to their appeal in advanced device fabrication.

5.3 Research and Development Platforms

For research institutions, lithium phosphate sputtering targets provide a low-risk, high-stability material system for exploring lithium-containing thin films without the handling difficulties associated with more reactive lithium compounds. This makes them ideal for exploratory studies, combinatorial material screening, and interface science research.

6. Manufacturing and Customization Advantages

Lithium phosphate sputtering targets can be fabricated in a variety of forms, including:

- Planar disc targets,

- Rectangular targets,

- Bonded targets with copper or titanium backing plates.

Their ceramic nature allows for controlled densification, which improves thermal conductivity and mechanical integrity during sputtering. Customization in terms of purity, density, and geometry further enhances their suitability for both laboratory and industrial environments.

Conclusion

The uniqueness of Lithium Phosphate Sputtering Targets lies not in a single outstanding parameter, but in a balanced combination of structural stability, sputtering reliability, and functional relevance. By embedding lithium within a robust phosphate framework, these targets overcome many of the challenges traditionally associated with lithium-based thin-film deposition.

From stable stoichiometric transfer and wide process windows to chemically resilient and lithium-compatible thin films, lithium phosphate sputtering targets offer a compelling solution for advanced thin-film applications. Their growing adoption in solid-state batteries, micro-energy systems, and functional coatings reflects a broader trend toward materials that combine performance with process practicality.

For researchers and engineers seeking a dependable pathway to lithium-containing thin films, lithium phosphate sputtering targets represent a uniquely capable and forward-looking material choice.