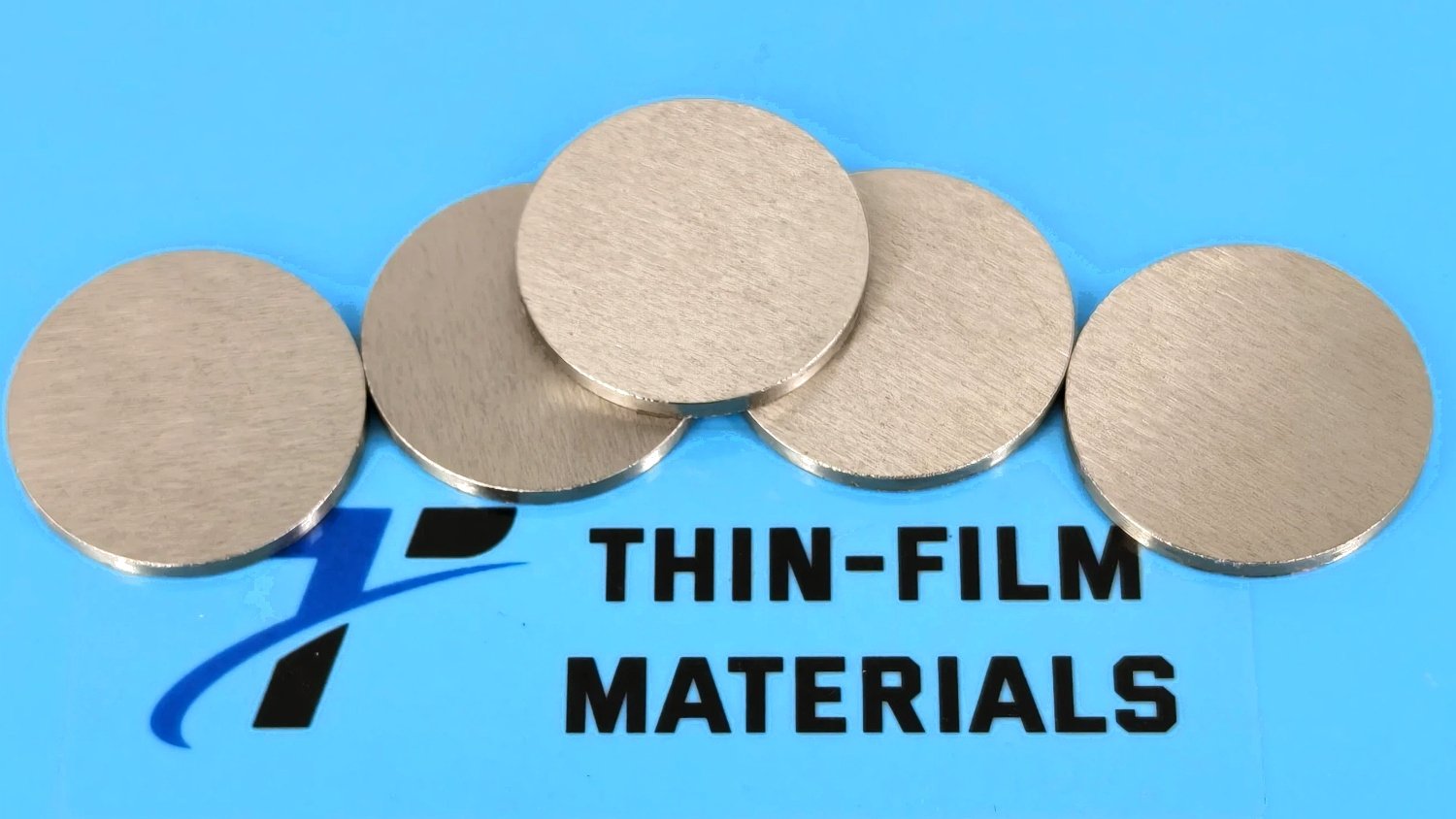

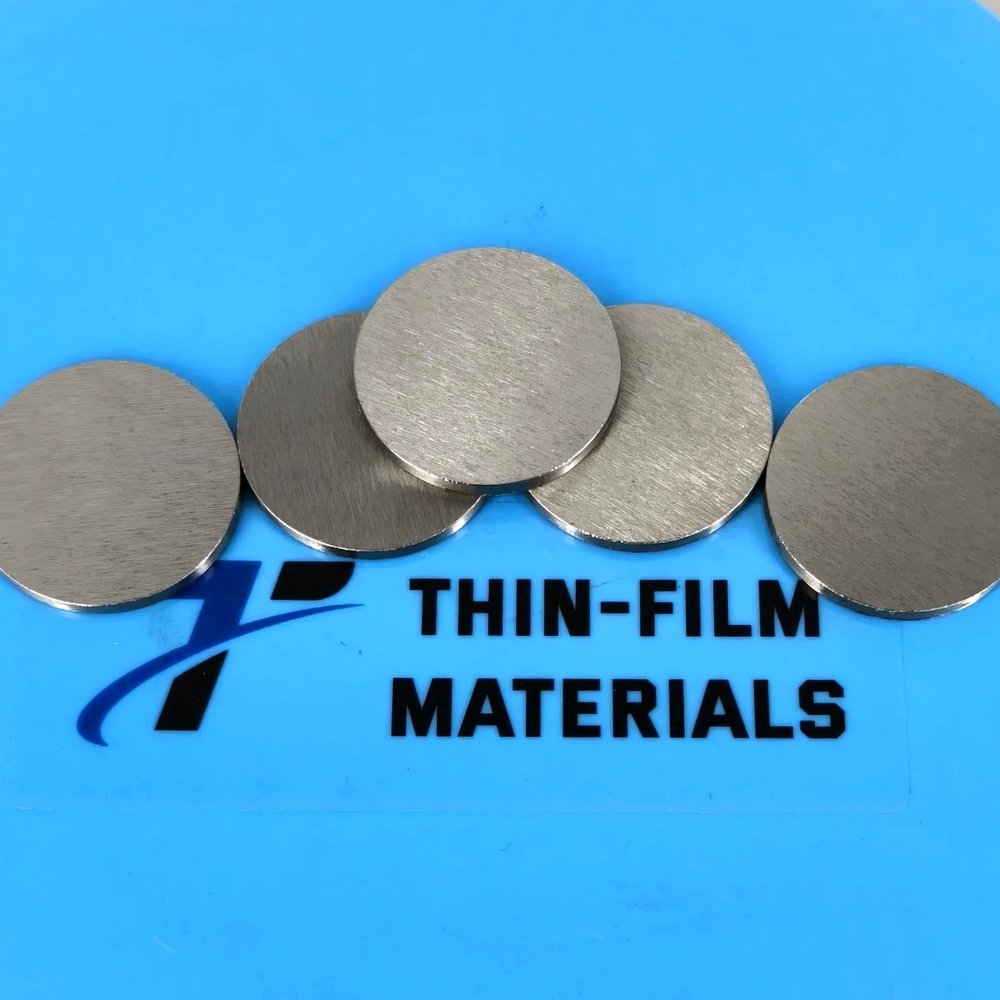

Zirconium Sputtering Target Description

Zirconium Sputtering Target Specification

| Material Type | Zirconium |

| Symbol | Zr |

| Melting Point | 1,852 °C |

| Color/Appearance | Silvery White, Metallic |

| Theoretical Density | 6.49 g/cc |

| Sputter | DC |

| Type of Bond | Indium, Elastomer |

| Comments | Alloys with W. Films oxidize readily. |

| Available Sizes | Dia.: 1.0″, 2.0″, 3.0″, 4.0″, 5.0″, 6.0″ Thick: 0.125″, 0.250″ |

We also offer other customized shapes and sizes of the sputtering targets; please Contact Us for more information.

Zirconium Sputtering Target Application

The zirconium sputtering target is widely used for thin film deposition, fuel cells, decoration, semiconductors, displays, LEDs, and photovoltaic devices. It also plays a crucial role in functional coatings and various optical information storage industries, as well as the glass coating industry, including car and architectural glass, optical communication, and more.

Zirconium metal itself is extensively used in the nuclear industry for cladding fuel elements in nuclear reactors due to its low absorption cross-section for neutrons. Its high resistance to corrosion by many common acids, alkalis, and seawater makes it invaluable in the chemical industry where corrosive agents are employed. Additionally, zirconium is used as an alloying agent in steel, for manufacturing surgical appliances, and for making superconducting magnets using zirconium/niobium alloys, which exhibit superconductivity at low temperatures. Alloys with zinc become magnetic below 35 K. Furthermore, zirconium is used as a “getter” in vacuum tubes, in flashbulbs for photography, explosive primers, and lamp filaments due to its diverse and robust properties.

Zirconium Sputtering Target Target Bonding

Specialized bonding services for Zirconium Sputtering Targets, including indium and elastomeric bonding techniques, enhance performance and durability. Thin Film Materials (TFM) ensures high-quality solutions that meet industry standards and customer needs.

We also offer custom machining of backing plates, which is essential for sputtering target assembly. This comprehensive approach improves target design flexibility and performance in thin film deposition. Our channels provide detailed information about bonding materials, methods, and services, helping clients make informed decisions.

Packing

Get Contact

TFM offers Zirconium Sputtering Targets in various forms, purities, sizes, and prices. We specialize in high-purity thin film deposition materials with optimal density and minimal grain sizes, which are ideal for semiconductor, CVD, and PVD applications in display and optics. Contact Us for current pricing on sputtering targets and other deposition materials that are not listed.

Reviews

There are no reviews yet.