Indium Oxide (In₂O₃) Sputtering Target

The Indium Oxide (In₂O₃) Sputtering Target from Thin Film Materials (TFM) is a high-purity ceramic target used in thin film deposition for semiconductors, optoelectronics, transparent conducting coatings, and energy devices. In₂O₃ is a wide bandgap semiconductor with excellent optical transparency and electrical conductivity, making it a vital material in advanced thin film research and production.

Detailed Description

TFM’s indium oxide sputtering targets are engineered with high density, uniform grain structure, and purities typically ranging from 99.9% (3N) to 99.99% (4N). This ensures consistent sputtering rates and high-quality films with low contamination.

Chemical Formula: In₂O₃

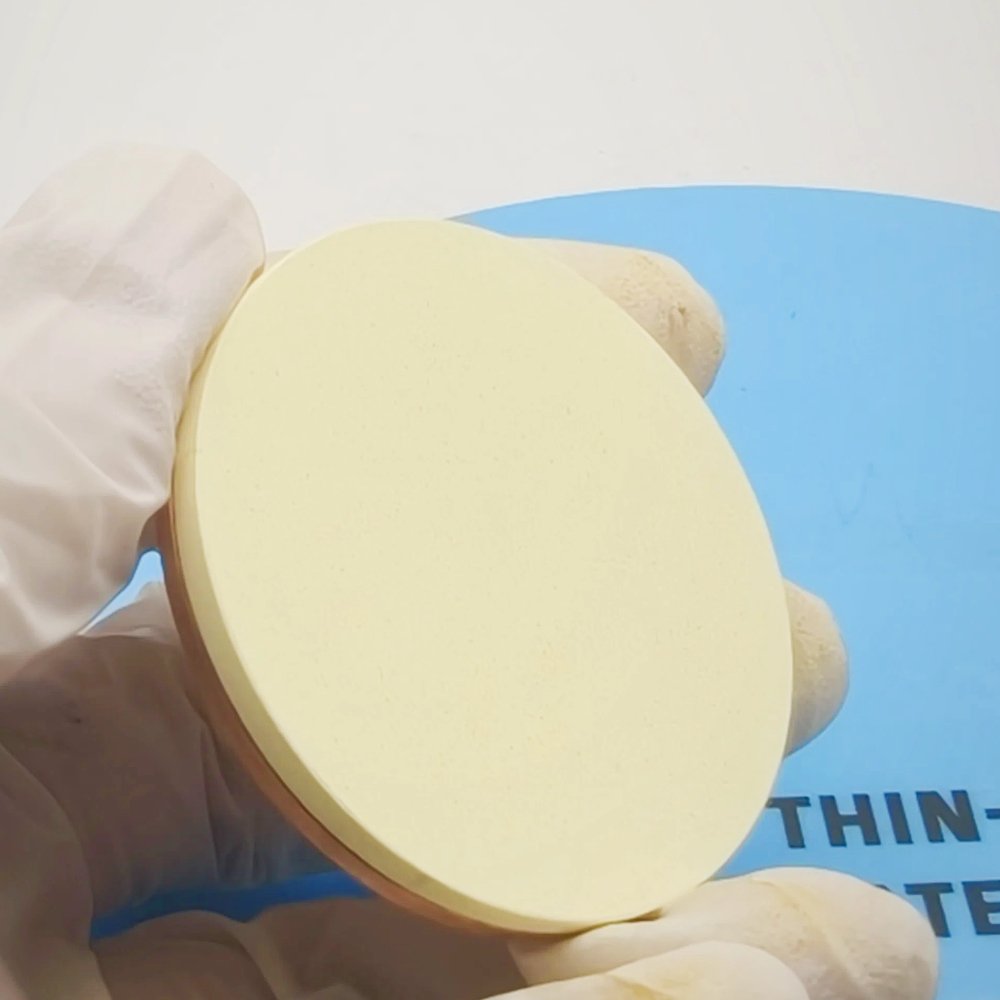

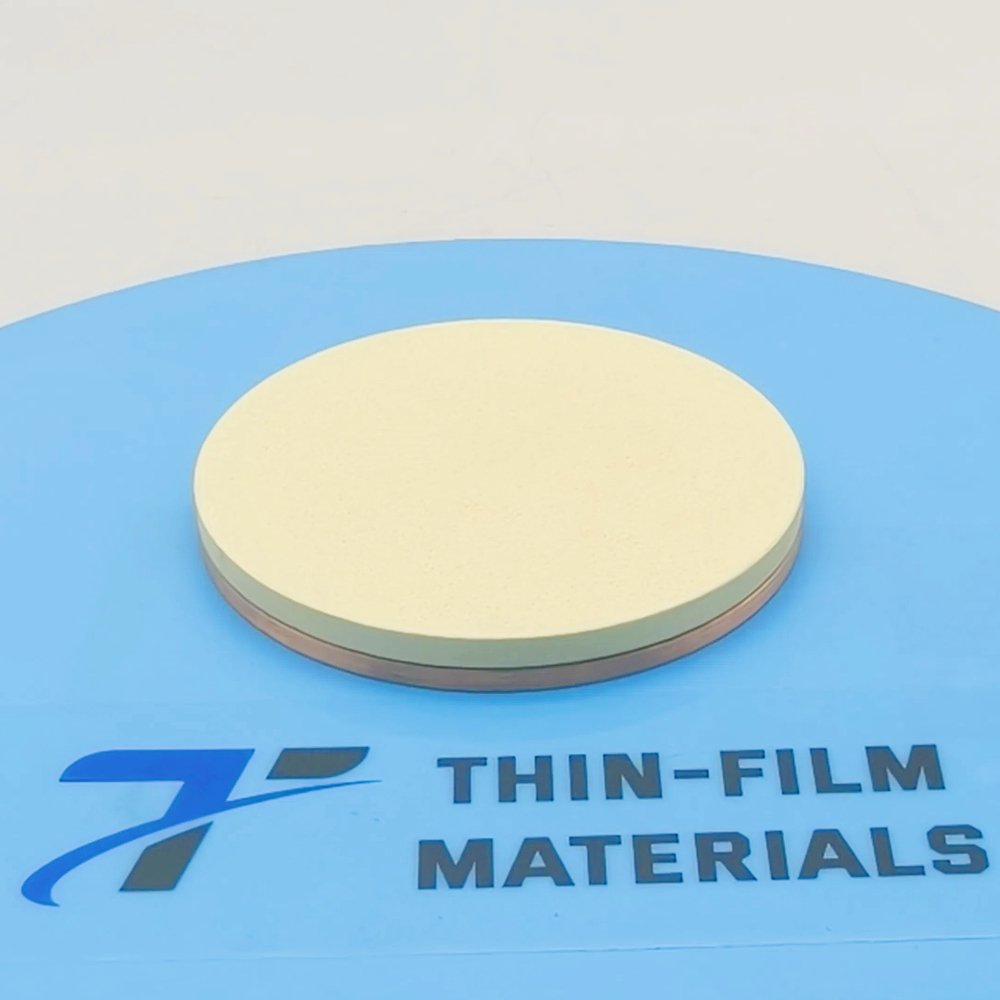

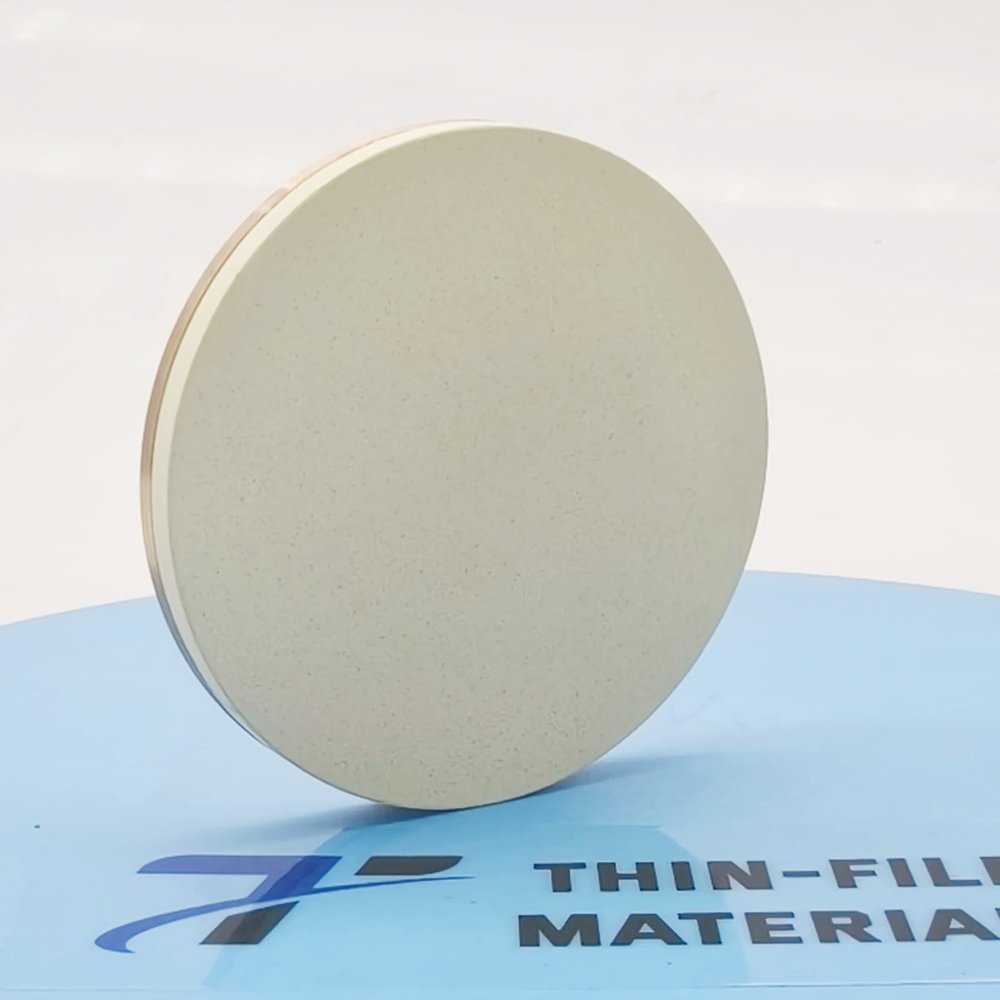

Appearance: Yellowish to pale brown ceramic

Density: ~7.18 g/cm³

Melting Point: ~1,910 °C

Crystal Structure: Cubic (bixbyite type)

We supply In₂O₃ sputtering targets in disc, rectangular, and custom forms. For improved thermal management and durability, bonding services with indium or elastomer onto copper or titanium backing plates are available.

Applications

Indium oxide sputtering targets are widely used in:

Transparent conducting oxides (TCOs) for displays, touchscreens, and photovoltaics

Optoelectronic devices such as LEDs, photodetectors, and sensors

Energy-efficient coatings on architectural and automotive glass

Semiconductors: buffer layers and thin film transistors (TFTs)

Research: development of functional oxide films and nanostructures

Technical Parameters

| Parameter | Typical Value / Range | Importance |

|---|---|---|

| Purity | 99.9% – 99.99% | Ensures minimal contamination for high-performance films |

| Diameter | 25 – 150 mm (custom up to 300 mm) | Fits common sputtering systems |

| Thickness | 3 – 6 mm | Controls sputtering rate and film thickness |

| Bonding Options | Indium / Elastomer | Improves adhesion and thermal stability |

| Backing Plate | Copper / Titanium | Provides mechanical support and efficient heat transfer |

Comparison with Related Materials

| Material | Key Advantage | Typical Application |

|---|---|---|

| Indium Oxide (In₂O₃) | Transparency + conductivity | Displays, sensors, solar cells |

| ITO (In₂O₃–SnO₂) | Higher conductivity & film uniformity | Touchscreens, photovoltaics |

| ZnO | Low cost, n-type semiconductor | Displays, transparent coatings |

FAQ

| Question | Answer |

|---|---|

| Can In₂O₃ sputtering targets be customized? | Yes, TFM provides custom diameters, thicknesses, and bonded targets. |

| Do you offer bonding services? | Yes, with indium or elastomer to Cu/Ti backing plates. |

| How are the targets packaged? | Each target is vacuum-sealed, cushioned with foam, and shipped in export-safe cartons or crates. |

| Which industries use In₂O₃ targets? | Semiconductors, displays, energy-efficient glass, and optoelectronics. |

Packaging

All Indium Oxide sputtering targets are vacuum-sealed, moisture-protected, and securely packaged with protective foam. Export-approved cartons or wooden crates ensure safe delivery worldwide.

Conclusion

The Indium Oxide (In₂O₃) Sputtering Target from TFM provides high purity, excellent transparency, and stable deposition properties, making it a reliable choice for advanced thin film applications. With customizable specifications and professional bonding services, our In₂O₃ targets support both research innovation and industrial-scale production.

For detailed specifications, quotations, and tailored solutions, please contact us at sales@thinfilmmaterials.com.

Reviews

There are no reviews yet.