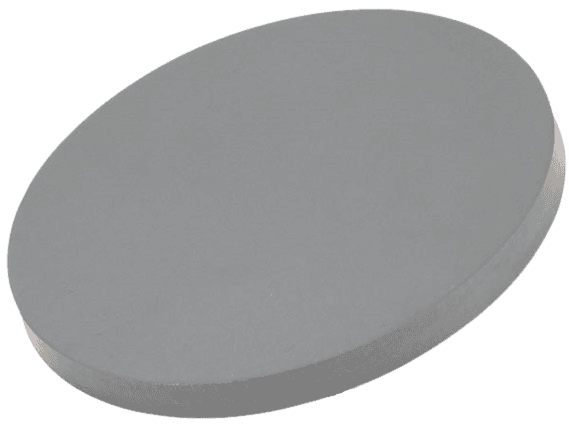

Iron Carbide Sputtering Target Description

Iron Carbide sputtering targets from TFM are high-quality carbide ceramic materials with the chemical formula Fe3C. Iron carbide, also known as cementite, is widely used in various applications due to its hardness and wear resistance. This material is commonly utilized in thin film deposition processes for applications in the semiconductor, display, LED, and photovoltaic industries, as well as for decorative and protective coatings.

Iron, also known as ferrum, is a chemical element with a rich history, dating back to its early use before 5000 BC. The name “iron” comes from the Anglo-Saxon word “iren,” while its Latin name “ferrum” is reflected in its chemical symbol “Fe.” Iron is a transition metal located in Period 4 and Group 8 of the periodic table, within the d-block. It has an atomic number of 26 and a relative atomic mass of 55.845(2) Dalton, with the number in brackets indicating the measurement uncertainty.

Iron, also known as ferrum, is a chemical element with a rich history, dating back to its early use before 5000 BC. The name “iron” comes from the Anglo-Saxon word “iren,” while its Latin name “ferrum” is reflected in its chemical symbol “Fe.” Iron is a transition metal located in Period 4 and Group 8 of the periodic table, within the d-block. It has an atomic number of 26 and a relative atomic mass of 55.845(2) Dalton, with the number in brackets indicating the measurement uncertainty.

Related Product: Iron Sputtering Target

Carbon, a chemical element symbolized as “C,” derives its name from the Latin word ‘carbo,’ meaning charcoal. This element has been known and utilized since around 3750 BC, with early uses attributed to the Egyptians and Sumerians. Carbon has an atomic number of 6 and is located in Period 2 and Group 14 of the periodic table, within the p-block. Its relative atomic mass is 12.0107(8) Dalton, with the number in brackets indicating the uncertainty of this measurement.

Carbon, a chemical element symbolized as “C,” derives its name from the Latin word ‘carbo,’ meaning charcoal. This element has been known and utilized since around 3750 BC, with early uses attributed to the Egyptians and Sumerians. Carbon has an atomic number of 6 and is located in Period 2 and Group 14 of the periodic table, within the p-block. Its relative atomic mass is 12.0107(8) Dalton, with the number in brackets indicating the uncertainty of this measurement.

Iron Carbide Sputtering Target Specification

| Compound Formula | Fe3C |

| Molecular Weight | 179.55 |

| Appearance | Solid |

| Melting Point | 1227 °C (2241 °F) |

| Density | 7.694 g/cm3 |

Iron Carbide Sputtering Target Packing

Our iron carbide sputtering targets are meticulously tagged and labeled externally to guarantee easy identification and strict quality control. We take great care in handling and packaging to prevent any damage during storage or transportation, ensuring that the targets arrive in perfect condition for use.

Reviews

There are no reviews yet.