Iridium Manganese Sputtering Target Description

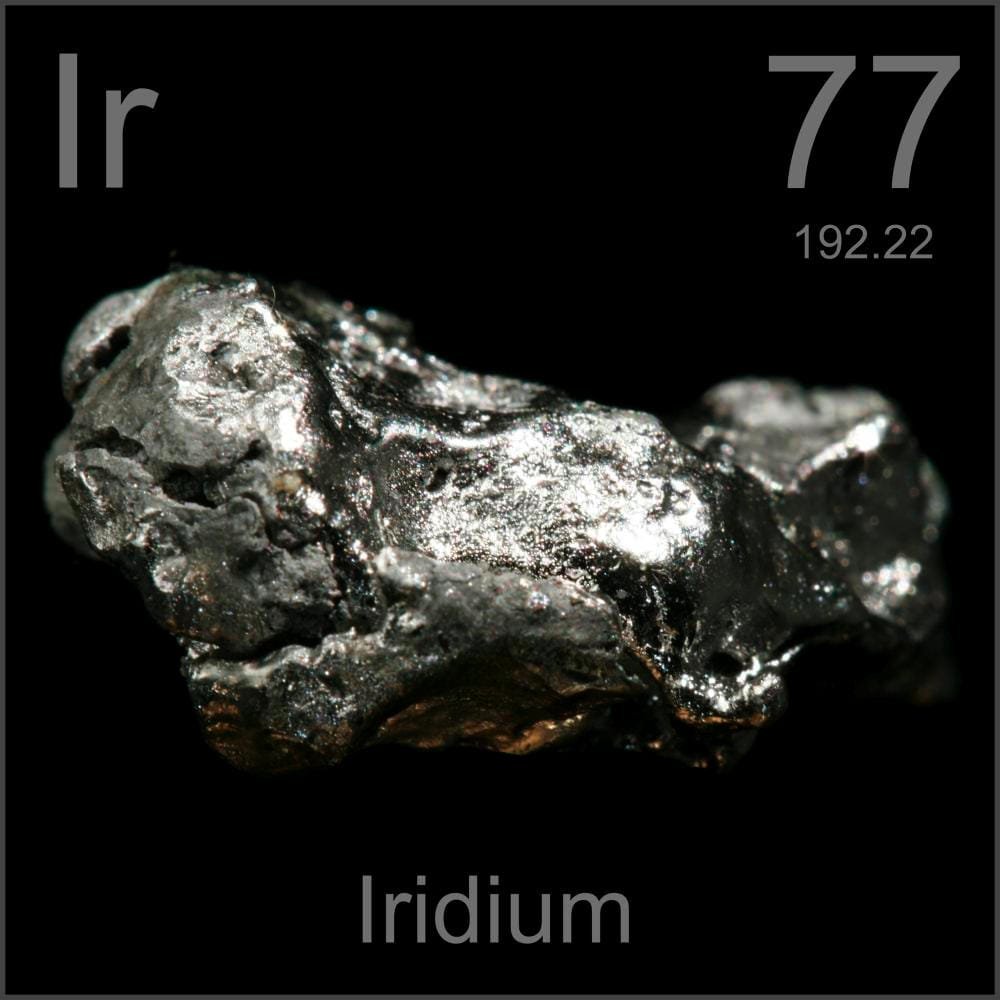

Iridium is a rare and exceptionally dense metal, known for its hardness, lustrous appearance, and brittleness. It is highly resistant to corrosion, making it one of the most enduring metals, withstanding attack from nearly all acids. Iridium is often recognized as the second densest element, following osmium, though calculations related to their space lattices suggest that iridium may, in fact, be denser.

Iridium is a rare and exceptionally dense metal, known for its hardness, lustrous appearance, and brittleness. It is highly resistant to corrosion, making it one of the most enduring metals, withstanding attack from nearly all acids. Iridium is often recognized as the second densest element, following osmium, though calculations related to their space lattices suggest that iridium may, in fact, be denser.

Manganese is a chemical element with a name derived either from the Latin word ‘magnes’, meaning magnet, or from the term ‘magnesia nigra’, referring to black magnesium oxide. First identified in 1770 by O. Bergman, its isolation was later achieved by G. Gahn. The chemical symbol for manganese is “Mn,” and it has an atomic number of 25. Located in Period 4 and Group 7 of the periodic table, manganese belongs to the d-block of elements. Its relative atomic mass is 54.938045(5) Dalton, with the number in parentheses indicating the degree of uncertainty.

Manganese is a chemical element with a name derived either from the Latin word ‘magnes’, meaning magnet, or from the term ‘magnesia nigra’, referring to black magnesium oxide. First identified in 1770 by O. Bergman, its isolation was later achieved by G. Gahn. The chemical symbol for manganese is “Mn,” and it has an atomic number of 25. Located in Period 4 and Group 7 of the periodic table, manganese belongs to the d-block of elements. Its relative atomic mass is 54.938045(5) Dalton, with the number in parentheses indicating the degree of uncertainty.

Related Products: Iridium Sputtering Target, Manganese Sputtering Target.

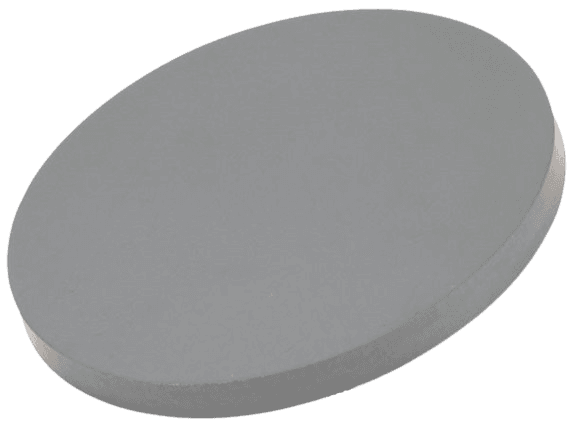

Iridium Manganese Sputtering Target Specifications

| Material Type | Iridium Manganese |

| Symbol | Ir/Mn |

| Color/Appearance | Gray metallic solid in various forms |

| Melting Point | 117 °C |

| Density | / |

| Available Sizes | Dia.: 2.0″, 3.0″, 4.0″, 5.0″, 6.0″ Thick: 0.125″, 0.250″ |

We also offer other customized shapes and sizes of the sputtering targets; please Contact Us for more information.

Iridium Manganese Sputtering Target Application

The Iridium Manganese Sputtering Target is ideal for a range of applications including thin film deposition, decorative coatings, and semiconductor fabrication. It is also used in the production of displays, LEDs, and photovoltaic devices. This target is suited for functional coatings and plays a role in optical information storage, as well as in the glass coating industry, such as automotive and architectural glass. Additionally, it is utilized in optical communication technologies.

Iridium Manganese Sputtering Target Packing

Our Iridium Manganese Sputtering Targets are meticulously tagged and labeled on the outside to facilitate easy identification and uphold rigorous quality control standards. We prioritize the protection of these targets from potential damage during both storage and transportation.

Reviews

There are no reviews yet.