Overview

Zirconia (ZrO₂) crucibles are renowned for their outstanding durability and high-performance capabilities in extreme temperatures. These crucibles are designed to endure temperatures as high as 2200°C, making them ideal for applications such as melting superalloys and precious metals. They excel in chemical inertness, thermal shock resistance, and resistance to both acids and alkalis.

Key Features

- Maximum Operating Temperature: Up to 2200°C, ideal for high-temperature processes.

- Chemical Resistance: Exceptional resistance to acids and alkalis, preserving material purity.

- Thermal Shock Resistance: Capable of handling rapid temperature changes up to 2200°C without damage.

- Material Composition: Manufactured from high-purity Zirconia (ZrO₂).

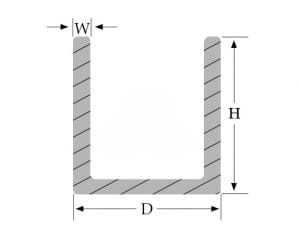

Specifications

| Working temperature | 2200℃ |

| Corrosion Resistant | Acids, alkalis |

| Approx. Capacity | 2~300 mL |

| Outer Diameter (OD) | 9~80 mm |

| Height | 15~80 mm |

| Wall thickness | 1.5~3.5 mm |

Cylindrical Shape ZrO₂ Crucible (Yttria-Stabilized Zirconia)

ZC0937 Zirconia Crucible (ZrO2 Crucible)

| No. | Item Code | Product Code | Shape | Capacity (mL) | Dimensions (mm) (Outer Diameter × Height × Wall Thickness) | Action |

| 1 | GG0906 | GG11255201011 | Cylindrical | 1.2 | Ø8 × 19 × 2–3 | |

| 2 | GG0282 | GG11175201001 | Cylindrical | 1.5 | Ø16 × 13 × 2–3 | |

| 3 | GG0919 | GG11656201002 | Cylindrical | 8 | Ø18 × 50 × 2–3 | |

| 4 | GG0920 | GG11575201002 | Cylindrical | 25 | Ø23 × 100 × 2–3 | |

| 5 | GG0283 | GG11185201001 | Cylindrical | 15 | Ø30 × 30 × 2–3 | |

| 6 | GG0284 | GG11195201001 | Cylindrical | 25 | Ø35 × 35 × 2–3 | |

| 7 | GG0285 | GG11205201001 | Cylindrical | 45 | Ø40 × 60 × 2–3 | |

| 8 | GG0286 | GG11215201001 | Cylindrical | 90 | Ø50 × 60 × 2–3 | |

| 9 | GG0287 | GG11225201001 | Cylindrical | 120 | Ø50 × 100 × 2–3 | |

| 10 | GG0288 | GG11235201001 | Cylindrical | 150 | Ø50 × 120 × 2–3 | |

| 11 | GG0922 | GG11595201002 | Cylindrical | 200 | Ø55 × 90 × 2–3 | |

| 12 | GG0289 | GG11245201001 | Cylindrical | 220 | Ø60 × 90 × 2–3 | |

| 13 | GG0905 | GG11255201001 | Cylindrical | 300 | Ø60 × 130 × 2–3 | |

| 14 | GG0924 | GG11325201002 | Cylindrical | 200 | Ø100 × 80 × 2–3 | |

| 15 | GG0923 | GG11315201002 | Cylindrical | 300 | Ø120 × 120 × 2– |

Custom sizes and shapes of Zirconia crucibles are available upon request. For personalized solutions, please reach out to us.

Applications

Zirconia Crucibles are indispensable in sectors demanding high purity and durability under severe conditions:

- Chemical Calcining: Perfect for processes that involve high temperatures and exposure to aggressive chemicals.

- Metal Casting and Melting: Ideal for melting precious metals and superalloys, ensuring a clean and uncontaminated process.

- Thermal Analysis: Used extensively in thermal analysis due to their stability at elevated temperatures.

Advanced Manufacturing and Customization

We offer bespoke crucibles designed to meet your specific requirements, including custom sizes and shapes. Our cutting-edge manufacturing techniques ensure each crucible adheres to rigorous quality standards, with precise control over purity, grain size, and microstructure.

Handling and Packaging

Each crucible is carefully packaged to maintain its pristine condition, minimizing any risk of damage during transit and storage.

Frequently Asked Questions (FAQs)

Q1: What makes Zirconia Crucibles stand out for high-temperature uses?

A1: Zirconia Crucibles are superior due to their excellent thermal shock resistance and chemical inertness, allowing them to operate at high temperatures without degrading or reacting with the processed materials.

Q2: Can I get Zirconia Crucibles in custom sizes?

A2: Yes, we offer customization for size and shape. Please contact us with your specifications.

Q3: Are these crucibles suitable for melting precious metals?

A3: Yes, they are highly suitable for melting precious metals as they are chemically inert and prevent contamination.

Q4: How should Zirconia Crucibles be handled and stored?

A4: Store the crucibles in a dry environment and handle them carefully to avoid impacts that could cause cracks or fractures.

Q5: What support do you offer if there are issues with the crucibles?

A5: We provide comprehensive customer support to address any technical issues or inquiries regarding our products.

Contact Us

For more information or to request a quote, please contact us. Our expert team is here to help you find the perfect Zirconia Crucible to suit your needs, ensuring optimal performance and value.

Reviews

There are no reviews yet.