Introduction

Claisse® Platinum Crucibles & Molds are precision-manufactured noble metal laboratory vessels designed for high-temperature fusion, analytical sample preparation, and advanced materials processing. Widely used in XRF (X-ray fluorescence) analysis and glass bead preparation, platinum crucibles and molds provide unmatched chemical inertness, thermal stability, and dimensional reliability.

In fusion laboratories where contamination control and repeatability are critical, platinum labware ensures consistent analytical accuracy and long service life under extreme thermal conditions.

Detailed Description

Claisse® Platinum Crucibles & Molds are typically fabricated from high-purity platinum (≥99.95%) or platinum-rhodium (Pt-Rh) alloys to enhance mechanical strength and resistance to deformation at elevated temperatures.

Key performance characteristics include:

High melting point (~1768°C for pure Pt)

Exceptional resistance to acids and molten fluxes

Excellent oxidation resistance at red heat

Dimensional stability during repeated heating cycles

Smooth polished interior surfaces for easy cleaning

Crucible configurations include:

Standard cylindrical crucibles

Tall-form crucibles

Low-form crucibles

Reinforced rim designs

Crucibles with matching platinum lids

Molds are engineered for:

Glass bead casting

Fusion sample preparation

Analytical pellet formation

High-purity material solidification

Pt-Rh alloys are often selected when enhanced mechanical strength is required, especially in automated fusion systems where repeated mechanical handling is involved.

Applications

Claisse® Platinum Crucibles & Molds are extensively used in:

XRF fusion sample preparation

Geological and mining laboratories

Cement and mineral analysis

Glass and ceramic melting

Chemical laboratory research

Precious metal refining

High-temperature analytical procedures

In analytical chemistry, platinum labware ensures minimal sample contamination and accurate quantitative results.

Technical Parameters

| Parameter | Typical Value / Range | Importance |

|---|---|---|

| Material | Pt ≥99.95% / Pt-Rh alloys | Ensures purity & durability |

| Melting Point | ~1768°C (Pt) | Supports extreme temperature use |

| Capacity | 5 – 300 mL (custom options) | Matches fusion requirements |

| Wall Thickness | 0.3 – 1.0 mm (custom) | Balances durability & heat transfer |

| Surface Finish | Polished interior | Reduces residue and contamination |

| Customization | Size, shape, alloy grade | Tailored to fusion systems |

Custom fabrication based on fusion machine compatibility and laboratory workflow is available.

Comparison with Alternative Crucible Materials

| Material | Key Advantage | Typical Application |

|---|---|---|

| Platinum (Pt) | Maximum chemical inertness | XRF & analytical fusion |

| Pt-Rh Alloy | Improved high-temp strength | Automated fusion systems |

| Zirconia | Cost-effective ceramic | General high-temp melting |

| Graphite | High thermal conductivity | Metal melting applications |

Compared to ceramic or graphite vessels, platinum crucibles provide superior chemical resistance and minimal contamination risk, making them essential for precision analytical laboratories.

FAQ

| Question | Answer |

|---|---|

| What alloy grades are available? | High-purity platinum and platinum-rhodium alloys are available. |

| Can crucibles be customized? | Yes, capacity, wall thickness, and design can be tailored. |

| Are lids supplied? | Matching platinum lids can be provided upon request. |

| Is platinum suitable for repeated thermal cycling? | Yes, platinum maintains structural integrity under repeated high-temperature cycles. |

| Is recycling or refining service available? | Precious metal reclaim options can be discussed depending on customer needs. |

Packaging

Our Claisse® Platinum Crucibles & Molds are meticulously tagged and labeled externally to ensure efficient identification and maintain high standards of quality control. Each unit is carefully protected with cushioning materials and secure packaging to prevent deformation or surface damage during storage and transportation.

Conclusion

Claisse® Platinum Crucibles & Molds provide reliable, high-purity performance for analytical fusion, glass bead preparation, and advanced laboratory applications. With superior thermal stability, chemical resistance, and customizable configurations, they remain the preferred choice for laboratories requiring precision and durability.

For detailed specifications and a quotation, please contact us at sales@thinfilmmaterials.com.

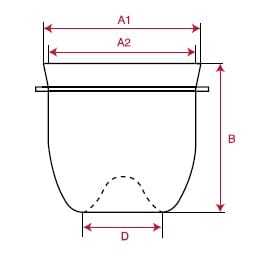

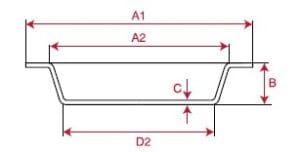

All weights are in grams and all dimensions are in millimeters.

Claisse® Platinum Crucibles

Code | Description | Capacity | B | A2 | D | A1 | Weight |

PT0501 | BIS with dimple | 25ml | 32 | 37 | 20 | 43 | 26 |

PT0502 | BIS reinforced with dimple | 25ml | 32 | 37 | 20 | 43 | 30 |

PT0503 | Flat base no dimple | 25ml | 35 | 35 | 21 | 44 | 26 |

PT0504 | Flat base no dimple | 25ml | 35 | 35 | 21 | 44 | 30 |

PT0505 | Optimix | 25ml | 32 | 37 | 20 | 43 | 30 |

Claisse® Platinum Molds

Code | D2 | A2 | A1 | B | C | Weight |

PT0506 | 30 | 31 | 39 | 6 | 0.6 | 18 |

PT0507 | 30 | 31 | 39 | 6 | 1 | 30 |

PT0508 | 32 | 34 | 42 | 6 | 0.6 | 21 |

PT0509 | 32 | 34 | 42 | 6 | 1 | 36 |

PT0510 | 35 | 37 | 44 | 6 | 0.6 | 25 |

PT0511 | 35 | 37 | 44 | 6 | 0.9 | 48 |

PT0512 | 38 | 41 | 49 | 6 | 0.6 | 29 |

PT0513 | 38 | 41 | 49 | 6 | 0.9 | 48 |

PT0514 | 40 | 42 | 49 | 6 | 0.6 | 34 |

PT0515 | 40 | 42 | 49 | 6 | 0.9 | 48 |

Reviews

There are no reviews yet.