Introduction

Spherical Cobalt-Based Powder (CoNiCrAlY) is a high-performance alloy powder engineered primarily for thermal spray and additive manufacturing applications requiring superior oxidation resistance and high-temperature durability. As a member of the MCrAlY family (where M = Co, Ni, or a combination), CoNiCrAlY is widely used as a bond coat material in thermal barrier coating (TBC) systems for gas turbines and aerospace components.

With its balanced composition of cobalt, nickel, chromium, aluminum, and yttrium, CoNiCrAlY delivers excellent adhesion, oxidation resistance, and structural stability under extreme thermal cycling conditions.

Detailed Description

CoNiCrAlY is designed to form a stable, protective oxide layer (primarily Al₂O₃) during high-temperature exposure. This thermally grown oxide (TGO) layer acts as a diffusion barrier, protecting the substrate and enhancing the lifespan of ceramic topcoats.

Typical nominal composition (wt%, customizable):

Co: Balance

Ni: 20–35%

Cr: 15–25%

Al: 5–10%

Y: 0.3–0.8%

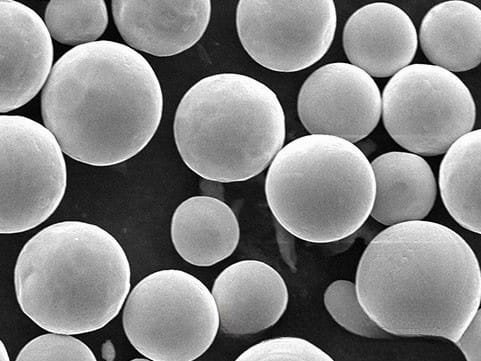

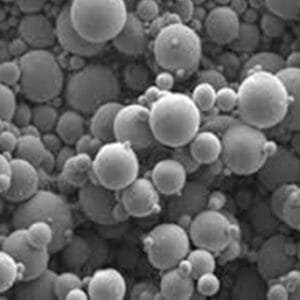

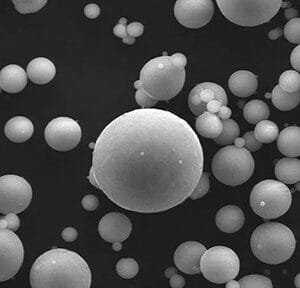

Spherical CoNiCrAlY Powder is generally produced via gas atomization to ensure:

High sphericity for improved flowability

Controlled particle size distribution (PSD)

Low oxygen content

Homogeneous alloy microstructure

Spherical morphology is critical for uniform feeding in plasma spray (APS), high-velocity oxy-fuel (HVOF), and laser cladding processes. The presence of yttrium improves oxide scale adherence, reducing spallation during thermal cycling.

CoNiCrAlY powders can be tailored in composition to optimize performance for specific turbine, aerospace, or industrial furnace applications.

Applications

Spherical CoNiCrAlY Powder is widely used in:

Thermal barrier coating (TBC) bond coats

Gas turbine blades and vanes

Combustion chambers and transition ducts

Aerospace engine components

Industrial furnace hardware

High-temperature corrosion-resistant coatings

Additive manufacturing of oxidation-resistant components

As a bond coat, CoNiCrAlY enhances adhesion between superalloy substrates and ceramic topcoats such as yttria-stabilized zirconia (YSZ).

Technical Parameters

| Parameter | Typical Value / Range | Importance |

|---|---|---|

| Alloy Type | CoNiCrAlY | Defines bond coat chemistry |

| Particle Size | 15–45 µm / 45–106 µm (custom) | Matches spray or AM process |

| Morphology | Spherical (gas atomized) | Ensures stable powder feeding |

| Oxygen Content | Controlled (low ppm) | Influences coating integrity |

| Melting Range | ~1250–1400°C (approx.) | Defines processing window |

| Application Method | APS / HVOF / Laser Cladding | Ensures coating performance |

Custom chemistry adjustments and PSD options are available based on specific performance requirements.

Comparison with Related MCrAlY Alloys

| Material | Key Advantage | Typical Application |

|---|---|---|

| CoNiCrAlY | Balanced oxidation resistance & thermal fatigue strength | Gas turbine bond coats |

| NiCrAlY | Strong oxidation resistance | Industrial high-temp coatings |

| CoCrAlY | Excellent hot corrosion resistance | Marine & turbine parts |

| Alloy 625 | Corrosion resistance without TBC system | Structural components |

Compared to NiCrAlY, CoNiCrAlY offers enhanced thermal fatigue resistance and mechanical stability in certain aerospace applications.

FAQ

| Question | Answer |

|---|---|

| Is this powder suitable for HVOF spraying? | Yes, spherical gas-atomized CoNiCrAlY is commonly used in HVOF systems. |

| Can composition be customized? | Yes, alloy chemistry can be adjusted to meet specific performance requirements. |

| Is it compatible with additive manufacturing? | Yes, selected PSD ranges can support laser-based AM processes. |

| What is the role of yttrium? | Yttrium improves oxide layer adhesion and reduces spallation. |

| Are certifications provided? | Yes, chemical composition reports and batch traceability are available. |

Packaging

Our Spherical Cobalt-Based Powder (CoNiCrAlY) are meticulously tagged and labeled externally to ensure efficient identification and maintain high standards of quality control. Powders are packaged in sealed, moisture-resistant containers to prevent contamination during storage and transportation.

Conclusion

Spherical Cobalt-Based Powder (CoNiCrAlY) delivers reliable oxidation resistance, thermal stability, and bond coat performance for demanding aerospace and industrial applications. With spherical morphology, controlled chemistry, and customizable particle size distribution, it supports advanced thermal spray and additive manufacturing technologies.

For detailed specifications and a quotation, please contact us at sales@thinfilmmaterials.com.

Reviews

There are no reviews yet.