High-entropy alloys (HEAs) are a class of materials that combine five or more metals in roughly equal proportions. These alloys have gained significant interest in the fields of materials science and engineering due to their exceptional properties. Research shows that certain high-entropy alloys exhibit superior specific strength compared to conventional alloys. Additionally, HEAs often demonstrate enhanced resistance to fracture, higher tensile strength, and improved resistance to corrosion and oxidation, making them highly desirable for advanced applications.

Specifications of FeAlNiCrX High-Entropy Alloys

| Particle size | 0-25,15-53,45-105,75-105μm |

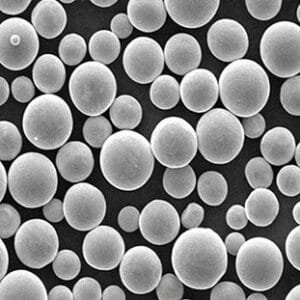

| Form | Spherical |

| Flowability | ≤20s |

| Apparent density | ≥4.0g/cc |

| Oxygen content | ≤300ppm |

| Nitrogen content | ≤100ppm |

| Composition | FeAlNiCr |

| FeAlNiCrMn | |

| FeAlNiCrAl | |

| FeAlNiCrTi | |

| FeAlNiCrCuTi | |

| FeAlNiCrMn |

Applications of FeAlNiCrX High-Entropy Alloys

High-entropy alloys like FeAlNiCrX are versatile and suitable for a range of manufacturing processes, including:

- Laser/Electron Beam Additive Manufacturing (SLM/EBM)

- Direct Laser Deposition (DLD)

- Powder Hot Isostatic Pressing (HIP)

- Metal Injection Molding (MIM)

These methods benefit from the unique properties of HEAs, particularly their strength and resistance to various forms of degradation.

Packaging Options for FeAlNiCrX High-Entropy Alloys

The packaging can be customized based on specific requirements, with typical options including:

- Weight: Available in 2.5kg, 5kg, or 25kg units

- Containers: Packaged in plastic bottles, cans, or iron containers for optimal protection

Reviews

There are no reviews yet.