Introduction

Niobium Powder is a high-performance refractory metal material widely used in advanced manufacturing, electronics, energy, and aerospace applications. Known for its high melting point, excellent corrosion resistance, and superconducting properties at low temperatures, niobium powder plays a critical role in powder metallurgy, additive manufacturing, capacitor technology, and advanced alloy development. High-purity niobium powder ensures consistent processing behavior and reliable end-use performance in both research and industrial environments.

Detailed Description

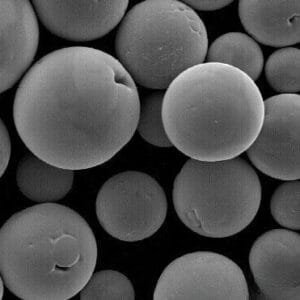

Niobium powder is produced through carefully controlled processes such as hydrogenation–dehydrogenation (HDH), reduction, or atomization, depending on the required particle size distribution and application. The resulting powder exhibits high chemical purity, controlled oxygen content, and stable morphology, which are essential for predictable sintering behavior and mechanical performance.

Due to niobium’s strong affinity for oxygen, powder handling and packaging are tightly controlled to minimize surface oxidation. High-quality niobium powder offers good flowability and compressibility, making it suitable for powder pressing, hot isostatic pressing (HIP), metal injection molding (MIM), and laser-based additive manufacturing processes.

Niobium powder is also an important precursor material for niobium-based alloys and compounds, enabling precise composition control in advanced material systems.

Applications

Niobium powder is widely used in:

Powder metallurgy components and near-net-shape parts

Additive manufacturing and 3D printing of refractory metal parts

Superconducting materials and research applications

Electrolytic capacitor anodes and electronic components

Aerospace and high-temperature structural alloys

Chemical processing and corrosion-resistant components

Academic and industrial materials research

Technical Parameters

| Parameter | Typical Value / Range | Importance |

|---|---|---|

| Material | Niobium (Nb) | Core refractory metal |

| Purity | 99.5% – 99.99% | Affects electrical and mechanical properties |

| Particle Size | 1 – 150 µm (custom available) | Determines sintering and flow behavior |

| Apparent Density | Application-dependent | Influences packing and compaction |

| Oxygen Content | Controlled, low ppm level | Critical for ductility and conductivity |

| Processing Routes | PM, HIP, AM, alloying | Broad manufacturing compatibility |

Comparison with Related Metal Powders

| Material | Key Advantage | Typical Application |

|---|---|---|

| Niobium Powder | High melting point, superconductivity | PM parts, superconductors |

| Tantalum Powder | Excellent biocompatibility | Medical implants, capacitors |

| Tungsten Powder | Extreme temperature resistance | High-density components |

| Titanium Powder | Lightweight, high strength | Aerospace, additive manufacturing |

FAQ

| Question | Answer |

|---|---|

| Can particle size be customized? | Yes, particle size distribution can be tailored to your process. |

| Is niobium powder suitable for additive manufacturing? | Yes, specific grades are available for AM and 3D printing. |

| How is the powder packaged? | Vacuum-sealed or inert-gas packaging to prevent oxidation. |

| Can small quantities be supplied? | Yes, laboratory and pilot-scale quantities are supported. |

| Is chemical analysis provided? | Yes, typical chemical composition data can be supplied upon request. |

Packaging

Our Niobium Powder is carefully vacuum-sealed or packed under inert gas and clearly labeled to ensure traceability and quality control. Moisture-resistant, shock-protective packaging is used to preserve powder integrity during storage and international transportation.

Conclusion

Niobium Powder offers exceptional performance for high-temperature, electronic, and advanced manufacturing applications. With controlled purity, flexible particle size options, and reliable quality, it is a trusted material choice for researchers, engineers, and industrial users worldwide.

For detailed specifications and a quotation, please contact us at sales@thinfilmmaterials.com.

Reviews

There are no reviews yet.