Lithium Iron Phosphate (LiFePO₄, LFP) sputtering targets represent a specialized class of functional ceramic targets developed primarily for thin-film electrochemical and energy-storage applications. Unlike LiFePO₄ powders used in conventional lithium-ion battery cathodes, sputtering targets are designed to enable precise thin-film deposition, supporting device-level integration, interface control, and fundamental electrochemical research.

This article provides a comprehensive and application-specific analysis of LiFePO₄ sputtering targets, focusing on where they are actually used, why sputtering is required, and what technical problems they solve in modern energy storage and electronic systems.

1. Background: Why LiFePO₄ in Thin-Film Form?

LiFePO₄ is widely recognized for its olivine crystal structure, strong P–O covalent bonding, and stable Fe²⁺/Fe³⁺ redox couple. These features give bulk LiFePO₄ cathodes:

- High thermal stability

- Flat discharge voltage (~3.4 V vs. Li/Li⁺)

- Long cycle life

- Excellent safety compared with Co- or Ni-based cathodes

However, bulk LiFePO₄ powder electrodes rely on carbon coating, binders, and liquid electrolytes, which are incompatible with micro-scale, solid-state, or integrated battery architectures. This limitation drives the demand for LiFePO₄ thin films, where sputtering becomes one of the most controllable fabrication routes.

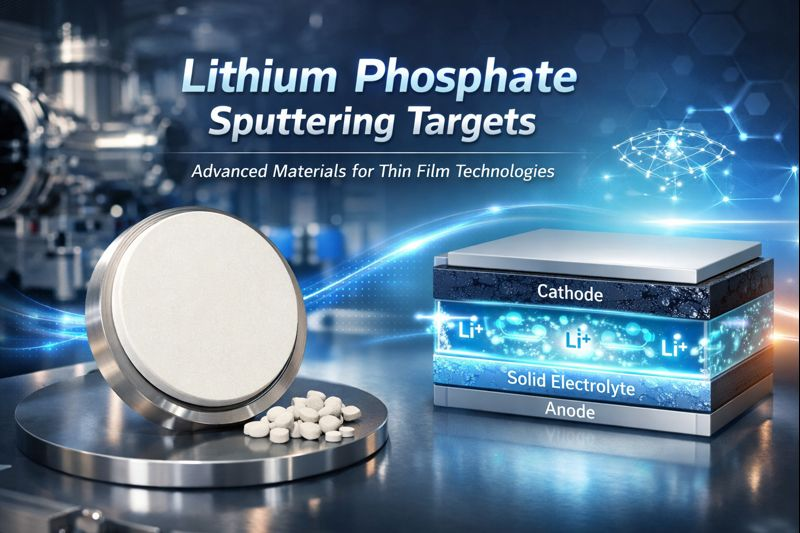

2. Thin-Film Lithium-Ion Batteries (TF-LIBs)

2.1 Cathode Layers in All-Solid or Semi-Solid Thin-Film Cells

The most mature and direct application of LiFePO₄ sputtering targets is in thin-film lithium-ion batteries, where LiFePO₄ serves as the cathode active layer.

Typical characteristics of sputtered LiFePO₄ cathodes include:

- Film thickness: 100 nm to 5 μm

- Deposition method: RF magnetron sputtering

- Post-deposition annealing to enhance crystallinity

- Substrates: Si, glass, sapphire, stainless steel, Pt-coated wafers

These thin-film batteries are widely used in:

- Microelectromechanical systems (MEMS)

- Wireless sensor nodes

- Backup power for real-time clocks and memory chips

- Self-powered microsystems

2.2 Why Sputtered LiFePO₄ Is Required

In TF-LIBs, the cathode layer must be:

- Binder-free

- Highly dense

- Uniform across wafer-scale substrates

- Precisely thickness-controlled

Sputtering targets enable atomic-scale control of film growth, ensuring consistent electrochemical behavior across the entire device area—something slurry-based methods cannot achieve.

3. Embedded Power Sources for MEMS and Integrated Electronics

3.1 On-Chip and Near-Chip Energy Storage

As electronic systems continue to miniaturize, embedded energy storage becomes increasingly important. LiFePO₄ sputtering targets are widely used to fabricate embedded cathode layers directly on electronic substrates.

Representative applications include:

- Implantable medical electronics

- Micro-sensors for pressure, gas, and biosensing

- Autonomous IoT sensor nodes

- Energy-harvesting systems with micro-storage buffers

3.2 Advantages of LiFePO₄ in Embedded Systems

Compared with LiCoO₂ or NMC thin films, LiFePO₄ offers:

- Lower risk of thermal runaway

- Higher tolerance to over-charge and over-discharge

- Reduced toxic and regulatory concerns

These properties are especially important in medical and safety-critical electronics, where device failure is unacceptable.

4. Solid-State Battery (SSB) Research and Development

4.1 Model Cathode Films for Interface Studies

In solid-state battery research, LiFePO₄ sputtering targets are extensively used to create model cathode thin films for fundamental studies.

Researchers use sputtered LiFePO₄ layers to investigate:

- Cathode–solid electrolyte interface stability

- Lithium diffusion pathways

- Space-charge layer formation

- Interfacial impedance evolution during cycling

Common material stacks include:

- LiFePO₄ / LiPON

- LiFePO₄ / LLZO

- LiFePO₄ / sulfide electrolytes

4.2 Why Sputtering Is Critical in SSB Research

Solid-state battery performance is often limited by interfacial phenomena rather than bulk material properties. Sputtering enables:

- Smooth, dense, and uniform cathode surfaces

- Well-defined interfaces without binder contamination

- High reproducibility across experiments

As a result, LiFePO₄ sputtering targets are standard materials in academic and industrial SSB laboratories.

5. Multilayer Thin-Film Battery Architectures

5.1 Complex Layer Stacks

Advanced thin-film batteries often employ multilayer architectures, consisting of:

- Metal current collectors (Pt, Au, Al)

- Cathode functional layers (LiFePO₄)

- Solid electrolytes

- Protective or buffer layers

LiFePO₄ sputtering targets must support:

- Stable sputtering rates

- Minimal lithium loss

- Uniform stoichiometry across the film

5.2 Role in Prototype and Pilot-Scale Manufacturing

Although thin-film batteries are not produced at the same scale as conventional LIBs, pilot-scale manufacturing requires:

- Batch-to-batch target consistency

- Long target lifetime

- Minimal compositional drift

High-density, well-sintered LiFePO₄ sputtering targets are therefore critical to ensure process stability during extended deposition runs.

6. Micro-Power Systems for Aerospace and Defense Applications

6.1 High-Reliability Energy Storage

LiFePO₄ thin films deposited from sputtering targets are increasingly used in high-reliability micro-power systems, particularly in:

- Aerospace electronics

- Satellite sensors

- Defense communication modules

- Extreme-environment instrumentation

6.2 Why LiFePO₄ Is Favored

In aerospace and defense environments, materials must withstand:

- Temperature extremes

- Radiation exposure

- Mechanical shock and vibration

LiFePO₄’s strong covalent bonding and stable crystal structure provide superior chemical and thermal robustness, making it a preferred cathode material for long-life, maintenance-free micro-energy systems.

7. Fundamental Electrochemical and Materials Research

7.1 Thin-Film Model Systems

Beyond applied devices, LiFePO₄ sputtering targets are widely used in fundamental materials research, including:

- Phase transition studies

- Li-ion diffusion kinetics

- Strain effects in thin-film cathodes

- Doping and substitution experiments

Thin-film LiFePO₄ allows researchers to isolate intrinsic material behavior without the complexities introduced by powders, binders, and conductive additives.

8. Technical Considerations for LiFePO₄ Sputtering Targets

8.1 Target Density and Microstructure

High-quality LiFePO₄ sputtering targets typically require:

- High sintered density (>95% theoretical)

- Fine and uniform grain size

- Minimal secondary phases

These factors directly affect sputtering yield, film composition, and target lifetime.

8.2 Lithium Stoichiometry Control

Lithium volatility is a known challenge during sputtering. Target composition and process conditions must be carefully optimized to:

- Minimize Li loss

- Ensure consistent film stoichiometry

- Maintain electrochemical performance

This is one reason why target fabrication quality is as important as deposition parameters.

9. Comparison with Powder-Based LiFePO₄

| Aspect | Powder-Based LiFePO₄ | Sputtered LiFePO₄ |

|---|---|---|

| Application scale | Bulk electrodes | Thin-film devices |

| Thickness control | Limited | nm–μm precision |

| Binder requirement | Required | None |

| Interface quality | Variable | Highly controlled |

| Integration capability | Low | Excellent |

LiFePO₄ sputtering targets therefore occupy a complementary, not competing, role relative to conventional cathode powders.

10. Conclusion

Lithium Iron Phosphate sputtering targets are not designed for conventional power battery production, but instead serve as enabling materials for thin-film, solid-state, and micro-scale energy storage technologies.

Their primary application areas include:

- Thin-film lithium-ion battery cathodes

- Embedded power sources in MEMS and microelectronics

- Solid-state battery interface and mechanism research

- Multilayer thin-film battery architectures

- High-reliability aerospace and defense micro-power systems

For researchers and engineers working at the intersection of energy storage, microfabrication, and advanced materials, LiFePO₄ sputtering targets provide a level of precision, reproducibility, and safety that cannot be achieved using powder-based approaches.

For detailed specifications, purity levels, target dimensions, and custom fabrication options, please contact sales@thinfilmmaterials.com.