Introduction

Lithium selenide (Li2Se) is an inorganic compound that has garnered significant attention in recent years due to its unique properties and potential applications in various fields, particularly in energy storage and semiconductor technology. As the demand for advanced materials continues to grow, understanding the role of lithium selenide and the importance of sputtering targets in its application becomes crucial. This article delves into the properties, uses, and significance of lithium selenide, with a particular focus on its role as a sputtering target in thin-film deposition processes.

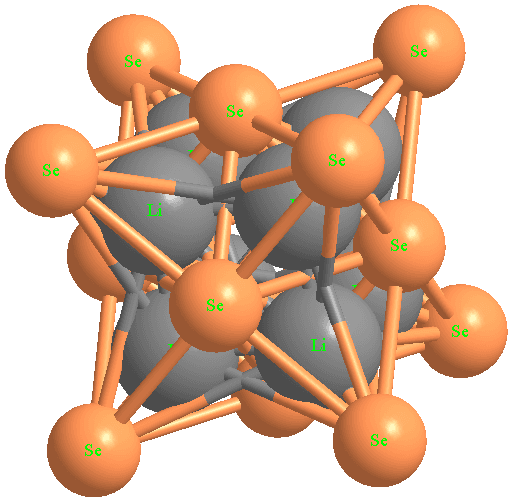

Properties of Lithium Selenide

Lithium selenide is a binary compound composed of lithium (Li) and selenium (Se) with the chemical formula Li2Se. It is a crystalline solid that exhibits several interesting properties:

- High Ionic Conductivity: Lithium selenide is known for its high ionic conductivity, making it a promising candidate for solid-state electrolytes in lithium-ion batteries. This property is crucial for enhancing the performance and safety of energy storage devices.

- Thermal Stability: Li2Se exhibits good thermal stability, which is essential for applications in high-temperature environments. This stability ensures that the material maintains its structural integrity and performance under varying thermal conditions.

- Optical Properties: Lithium selenide has unique optical properties, including a wide bandgap, which makes it suitable for use in optoelectronic devices. Its ability to absorb and emit light in specific wavelengths can be harnessed in photovoltaic cells and light-emitting diodes (LEDs).

- Chemical Reactivity: Li2Se is highly reactive with water and moisture, which necessitates careful handling and storage. This reactivity, however, can be advantageous in certain chemical synthesis processes.

Applications of Lithium Selenide

The unique properties of lithium selenide make it suitable for a wide range of applications, particularly in the fields of energy storage, electronics, and materials science. Some of the key applications include:

1. Lithium-Ion Batteries

One of the most promising applications of lithium selenide is in the development of advanced lithium-ion batteries. As a solid-state electrolyte, Li2Se can enhance the ionic conductivity and thermal stability of the battery, leading to improved performance and safety. The high ionic conductivity of Li2Se allows for faster charge and discharge rates, which is critical for applications in electric vehicles (EVs) and portable electronics.

Moreover, the use of lithium selenide in solid-state batteries can potentially eliminate the need for liquid electrolytes, which are prone to leakage and pose safety risks. Solid-state batteries with Li2Se electrolytes are expected to offer higher energy densities, longer lifespans, and improved safety profiles compared to conventional lithium-ion batteries.

2. Thin-Film Deposition

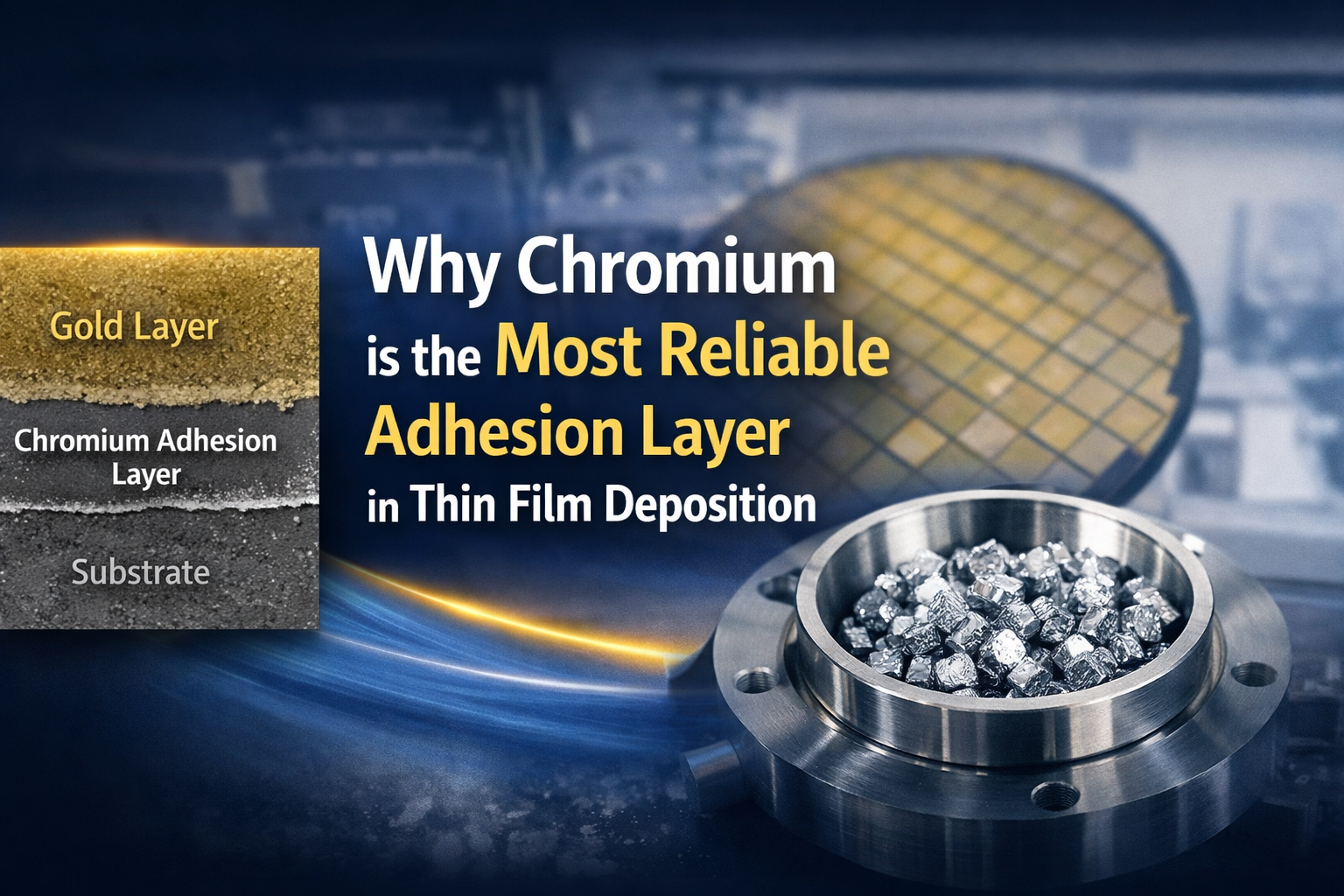

Lithium selenide is also used as a sputtering target in thin-film deposition processes. Sputtering is a widely used technique in the semiconductor industry for depositing thin films of materials onto substrates. The sputtering process involves bombarding a target material with high-energy ions, causing atoms to be ejected from the target and deposited onto a substrate.

In the case of lithium selenide, sputtering targets are used to deposit thin films of Li2Se onto various substrates for applications in optoelectronics, photovoltaics, and energy storage. The ability to precisely control the thickness and composition of the deposited films is crucial for optimizing the performance of devices such as solar cells, LEDs, and thin-film batteries.

3. Optoelectronic Devices

The optical properties of lithium selenide make it a suitable material for use in optoelectronic devices. For instance, Li2Se can be used as a buffer layer in thin-film solar cells to improve the efficiency of light absorption and charge carrier separation. Additionally, its wide bandgap makes it a potential candidate for use in ultraviolet (UV) photodetectors and LEDs.

4. Chemical Synthesis

Lithium selenide is also used as a precursor in the synthesis of other selenium-containing compounds. Its high reactivity with water and other chemicals makes it a valuable reagent in organic and inorganic synthesis processes. For example, Li2Se can be used to synthesize selenides of other metals, which have applications in catalysis, sensors, and thermoelectric materials.

Importance of Sputtering Targets in Thin-Film Deposition

Sputtering targets play a critical role in the thin-film deposition process, and the choice of target material directly impacts the quality and performance of the deposited films. In the context of lithium selenide, sputtering targets are essential for producing high-quality Li2Se thin films with precise control over their properties. The importance of sputtering targets can be understood through the following aspects:

1. Material Purity and Composition

The purity and composition of the sputtering target are crucial for achieving the desired properties in the deposited thin films. High-purity lithium selenide targets ensure that the resulting films are free from impurities that could adversely affect their performance. Additionally, the stoichiometry of the target material must be carefully controlled to achieve the correct composition of Li2Se in the deposited films.

2. Film Uniformity and Thickness Control

Sputtering targets must have a uniform composition and density to ensure the deposition of uniform thin films. Non-uniform targets can lead to variations in film thickness and composition, which can negatively impact the performance of the final device. The ability to control the thickness of the deposited films is particularly important in applications such as thin-film batteries and optoelectronic devices, where precise thickness control is essential for optimal performance.

3. Target Morphology and Microstructure

The morphology and microstructure of the sputtering target also play a significant role in the deposition process. Targets with a fine-grained microstructure and smooth surface finish are preferred, as they result in more consistent and reproducible thin films. The target’s microstructure can influence the sputtering rate, the energy distribution of the ejected atoms, and the overall quality of the deposited films.

4. Target Longevity and Cost-Effectiveness

The durability and longevity of sputtering targets are important considerations, especially in industrial-scale deposition processes. High-quality lithium selenide targets with good mechanical strength and thermal stability can withstand prolonged sputtering without significant degradation. This not only reduces the frequency of target replacement but also contributes to cost-effectiveness in large-scale production.

Challenges and Future Perspectives

Despite the promising applications of lithium selenide, there are several challenges that need to be addressed to fully realize its potential. Some of the key challenges include:

1. Handling and Storage

Lithium selenide is highly reactive with moisture and air, which makes its handling and storage challenging. Special precautions, such as the use of inert atmospheres and moisture-free environments, are required to prevent degradation and ensure the material’s stability. Developing effective encapsulation and storage solutions will be crucial for the widespread adoption of Li2Se in various applications.

2. Synthesis and Processing

The synthesis of high-purity lithium selenide with controlled stoichiometry is a complex process that requires precise control over reaction conditions. Advances in synthesis techniques, such as solid-state reactions and chemical vapor deposition, are needed to produce high-quality Li2Se with consistent properties. Additionally, optimizing the processing parameters for sputtering targets, such as sintering temperature and pressure, is essential for achieving the desired target properties.

3. Integration with Existing Technologies

Integrating lithium selenide into existing technologies, such as lithium-ion batteries and thin-film devices, requires careful consideration of compatibility and interface engineering. For example, in solid-state batteries, the interface between the Li2Se electrolyte and the electrode materials must be optimized to minimize interfacial resistance and enhance charge transfer. Similarly, in thin-film devices, the adhesion and compatibility of Li2Se films with underlying substrates must be carefully controlled to ensure device performance and reliability.

4. Scalability and Cost

Scaling up the production of lithium selenide and its sputtering targets while maintaining high quality and consistency is a significant challenge. Developing cost-effective and scalable synthesis and processing methods will be essential for the commercial viability of Li2Se-based technologies. Additionally, reducing the cost of raw materials and production processes will be crucial for making lithium selenide competitive with other materials in the market.

Conclusion

Lithium selenide is a versatile material with a wide range of applications in energy storage, electronics, and materials science. Its unique properties, such as high ionic conductivity, thermal stability, and optical characteristics, make it a promising candidate for advanced technologies, including solid-state batteries, thin-film devices, and optoelectronic applications. The use of lithium selenide sputtering targets in thin-film deposition processes is particularly important for achieving high-quality films with precise control over their properties.

However, several challenges, including handling and storage, synthesis and processing, integration with existing technologies, and scalability, need to be addressed to fully realize the potential of lithium selenide. Continued research and development efforts in these areas will be crucial for advancing the state-of-the-art in Li2Se-based technologies and unlocking new opportunities for innovation.

As the demand for advanced materials continues to grow, understanding the properties, uses, and importance of lithium selenide and its sputtering targets will be essential for driving progress in energy storage, electronics, and beyond. With ongoing advancements in materials science and engineering, lithium selenide is poised to play a significant role in shaping the future of technology.