Furnace Chamber

High-temperature Vacuum Furnace Chambers are critical components in industries requiring precise control over extreme heat and vacuum environments. These chambers, built with materials like molybdenum and tungsten, ensure high thermal resistance, strength, and stability under intense conditions. They are widely used in applications such as sintering, heat treatment, brazing, and crystal growth, where material purity and process integrity are paramount.

Benefits of High-Temperature Vacuum Furnace Chambers

- Precision: Enables tight control over temperature and atmosphere for accurate processing of materials.

- Material Integrity: Vacuum environments prevent contamination and oxidation, preserving the purity of the materials.

- Durability: Molybdenum and tungsten chambers are engineered to last, providing excellent resistance to high-temperature degradation.

- Versatility: Suitable for a range of industrial applications, from metal processing to research and development in advanced materials.

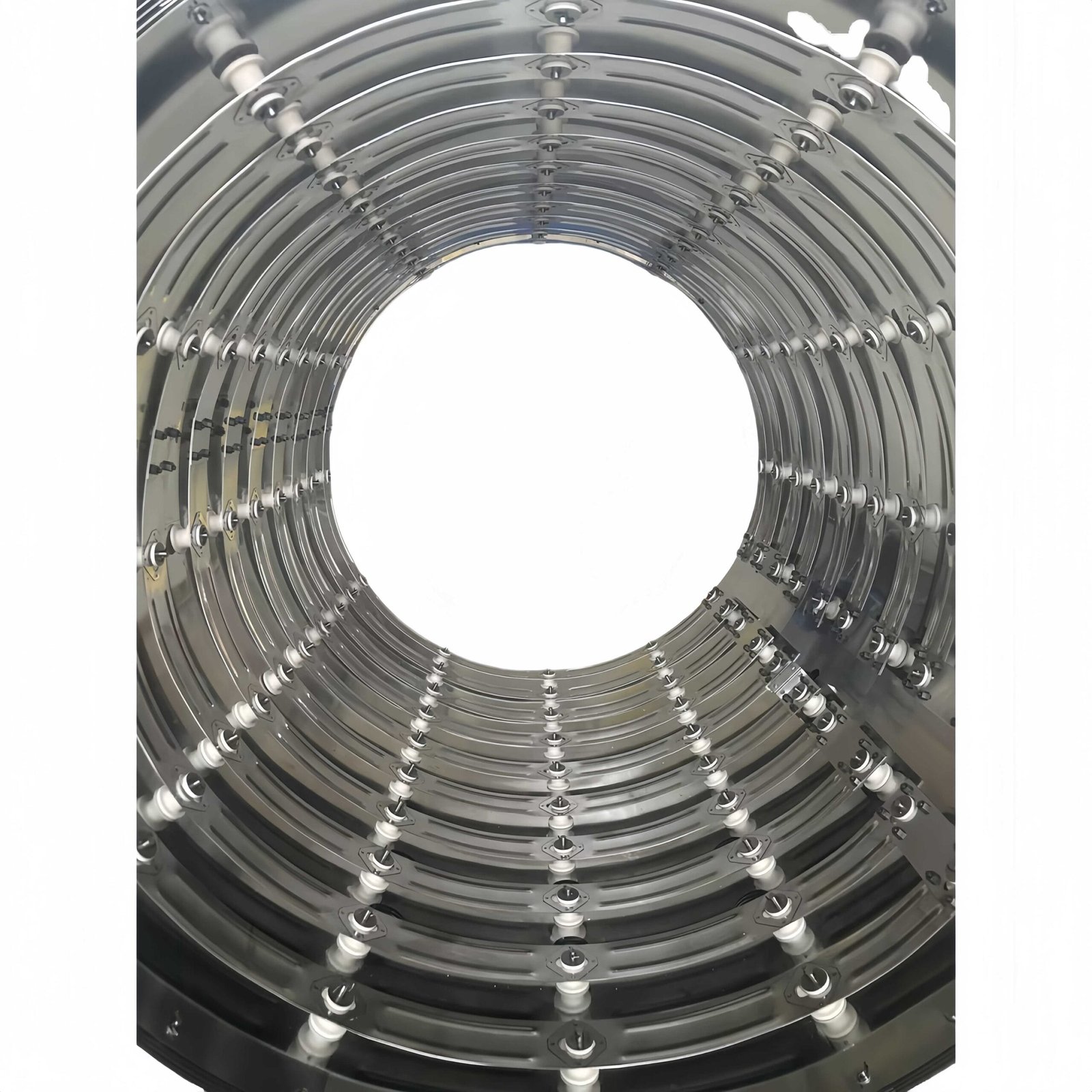

Molybdenum Vacuum Furnace Chamber

Molybdenum (Mo) is a refractory metal known for its high melting point, exceptional strength at elevated temperatures, and excellent thermal conductivity. Molybdenum vacuum furnace chambers are designed to handle high-temperature processes while maintaining structural integrity in a vacuum environment.

Key Features:

- High Melting Point: Molybdenum’s melting point exceeds 2600°C, making it suitable for heat-intensive applications.

- Oxidation Resistance: Operates in a vacuum environment to prevent oxidation, ensuring the purity of processed materials.

- Thermal Stability: Molybdenum maintains its strength and structural properties under high heat, allowing for precise control of heating and cooling cycles.

- Applications: Sintering, brazing, heat treatment of metals, and processing of ceramic components.

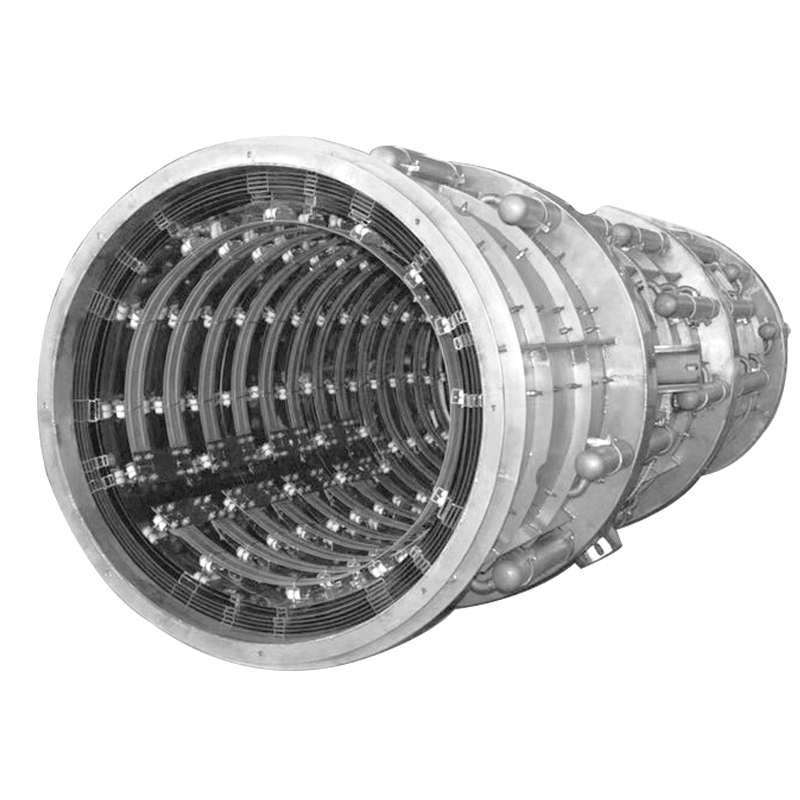

Tungsten Vacuum Furnace Chamber

Tungsten (W), with its extremely high melting point of over 3400°C, is another preferred material for high-temperature vacuum furnace chambers. Its superior heat resistance and mechanical properties make it ideal for even more demanding applications.

Key Features:

- Ultra-High Heat Resistance: Tungsten can withstand the highest temperatures of any refractory metal, making it ideal for ultra-high temperature processes.

- Structural Integrity: Exceptional strength and rigidity at elevated temperatures ensure long service life even in the most extreme environments.

- Low Vapor Pressure: Tungsten’s low vapor pressure minimizes material evaporation during high-temperature processing in a vacuum, ensuring the chamber’s longevity and operational efficiency.

- Applications: Ideal for crystal growth, advanced material research, aerospace, and nuclear industries.

Applications

Sintering of Powdered Metals and Ceramics

Vacuum furnace chambers are widely used for the sintering of metal powders (like tungsten carbide) and advanced ceramics. The high temperatures and vacuum environment help consolidate materials into solid objects while preventing oxidation and contamination.Brazing

These chambers are ideal for vacuum brazing, where metals are joined without flux, ensuring clean, strong joints for aerospace, electronics, and automotive industries.Heat Treatment of High-Strength Alloys

Molybdenum and tungsten furnace chambers are used for the heat treatment of superalloys, stainless steel, titanium, and other metals. This enhances their mechanical properties, such as toughness, strength, and fatigue resistance.Crystal Growth

Vacuum furnace chambers support the production of large single crystals, including sapphire, silicon, and gallium arsenide, for use in semiconductors, LEDs, and solar cells.Vacuum Annealing

Used to soften metals and relieve internal stresses without oxidation, vacuum annealing is crucial for industries dealing with specialty steels, titanium alloys, and other reactive metals.Graphitization of Carbon-Based Materials

In processes where graphite is formed from carbon-based materials, such as in the production of electrodes for electric arc furnaces, vacuum furnace chambers ensure the integrity of the material at high temperatures.Carburizing

The carburizing process involves infusing carbon into steel parts to improve their surface hardness. High-temperature vacuum furnace chambers allow this to be done with precise control, critical for gear manufacturing and tool production.Vacuum Melting and Alloy Production

High-purity metals and specialty alloys like titanium, zirconium, and other reactive metals can be melted and cast in a vacuum environment to prevent contamination and achieve the desired alloy composition.Degassing of Metals and Alloys

Vacuum furnace chambers are used to remove dissolved gases such as hydrogen and nitrogen from molten metals, which improves the quality and performance of components like turbine blades and aerospace parts.Coating and Deposition Processes

Used in physical vapor deposition (PVD) and chemical vapor deposition (CVD), vacuum chambers enable the creation of thin film coatings on metals, semiconductors, and other substrates, ensuring high adhesion and purity in electronics, optics, and tooling industries.Nuclear Fuel Fabrication

In nuclear technology, these chambers are used to sinter and process nuclear fuel pellets made from uranium or plutonium oxide, ensuring their durability and efficiency for use in reactors.Aerospace Component Manufacturing

Vacuum furnace chambers allow for the precise thermal processing of components used in aerospace applications, including jet engine parts, turbines, and high-performance structural materials.Medical Device Manufacturing

Components such as surgical tools, implants, and medical instruments require high-purity and oxidation-free processing, which can be achieved through vacuum heat treatment.Magnet Manufacturing

Production of neodymium and samarium-cobalt magnets requires vacuum sintering processes to maintain magnetic properties and structural integrity, which is best done in high-temperature vacuum furnace chambers.Hydrogen Embrittlement Relief

Post-processing for metals exposed to hydrogen, such as high-strength steels, benefits from vacuum heat treatment to relieve hydrogen embrittlement, essential in aerospace and automotive industries.Superconductor Fabrication

Manufacturing superconducting materials, such as niobium-tin and yttrium-barium-copper oxide (YBCO), requires high-temperature processing in a vacuum environment to ensure the material’s superconducting properties are maintained.Tool and Die Manufacturing

Vacuum furnace chambers are used to treat cutting tools, molds, and dies for enhanced hardness and wear resistance, which are crucial in manufacturing industries, including injection molding and metal stamping.

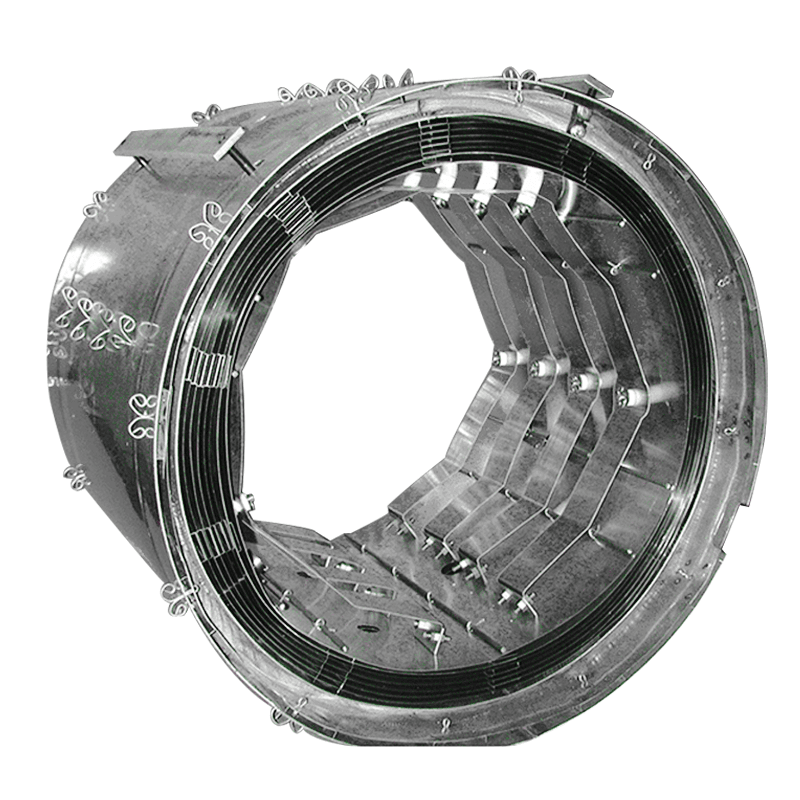

Why Choose TFM’s High-Temperature Vacuum Furnace Chambers?

At TFM (Thin Film Materials Engineering), we specialize in delivering cutting-edge high-temperature vacuum furnace chambers made from premium-grade molybdenum and tungsten. Our products are crafted to meet the stringent requirements of today’s advanced manufacturing and research industries, ensuring exceptional performance and reliability.

Our Commitment:

- Quality Materials: We use only the highest purity molybdenum and tungsten to ensure optimal performance.

- Custom Solutions: Chambers can be tailored to meet the specific needs of your application.

- Expertise in Vacuum Technology: With decades of experience, we provide expert guidance and support to help optimize your processes.

For more information on our Molybdenum and Tungsten Vacuum Furnace Chambers or to discuss your specific needs, Contact Us today!

Our Factory

Cetificates